China Aluminum Frame Extrusion Profiles - Large Cross Extrusion Section for Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

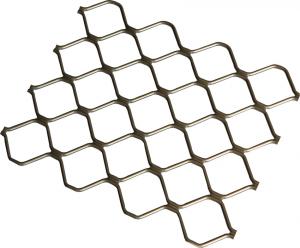

Large Cross Extrusion Section For Tubes

1. Surface: Mill surface treatment or others.

2. Alloy:6082T6 alloy temper

3. Size:various dimensions in order to meet customer’s requirement

4. Life time: Last for 50 years

5. Standard: EN755-9 standard

6. Advantage:

The tubes are resistant to water corrosion, many marine-based industries use these tubes to make parts. Tubes made from this metal are used to manufacture submarines, ships, boats and large ferries. Also many large industries have started using tubes made from aluminium because it is easy to make designs and shapes from these tubes. Another benefit of using these tubes is that their thickness can be varied depending on the specification required.

The alloy temper with 6082 T6 which allows this structure to maintain good formability, good weldability, high hardness, good workability and good interface characteristics. Easy processing, easy coating and good corrosion resistance, oxidation resistance.

7. Package:

Each profile is wrapped by the particular paper to avoid the scratching between each profile and also prevent the moisture in the air. Outside the bundle is fixed with the four wooden boards including support board vertically and base board on horizontal level. There are steel belts outside the boards to strap and tighten.

- Q: Knowledge of aluminum profile warehouse management (detail)

- Warehouse management is the main task required under the factories and production equipment condition of overall planning, rational layout; to strengthen the internal economic responsibility system, scientific division, forming material export management guarantee system; business must implement the work quality standardization, application of modern management technology and the ABC classification method, and constantly improve the level of warehouse management. The main work is material inspection, income, inventory, storage and custody of materials, materials delivery, billing statements, etc.

- Q: Can aluminum profiles be used for greenhouse construction?

- Indeed, greenhouse construction can make use of aluminum profiles. The durability, lightweight characteristics, and corrosion resistance of aluminum make it a favored selection for greenhouse frames. Moreover, aluminum proves to be easily manageable, enabling flexibility in design and construction. The utilization of aluminum profiles yields a robust and steady structure capable of enduring severe weather conditions and providing enduring support for greenhouse coverings. Furthermore, aluminum frames necessitate minimal upkeep and possess a lengthier lifespan in comparison to alternative materials, rendering them a cost-efficient choice for greenhouse construction.

- Q: What are the specifications of aluminium alloy door and window profiles?

- The aluminum alloy door and window profiles of the same size series are quite complex in shape and size. Must be analyzed and treated in accordance with the drawings.The section of aluminum door and window profile is divided into solid section and hollow section according to the shape of section, and the application of hollow profile is larger.Aluminum door and window profiles of wall thickness, for aluminum alloy window of not less than 1.4mm, with aluminum alloy door is not less than 2mm.The length, size, dividing ruler, double ruler and indefinite ruler of aluminum door and window profiles are three kinds. Fixed length generally not more than 6m, variable length is not less than 1m.

- Q: This question asks for methods to guarantee the high quality of aluminum profiles used in a construction project.

- <p>To ensure high-quality aluminum profiles for your building project, start by selecting profiles from reputable manufacturers known for quality. Check for certifications such as ISO 9001 for quality management systems. Inspect the profiles for uniformity in thickness and color, and ensure they are free from defects like dents or scratches. Request third-party test reports to verify the strength and durability of the profiles. Additionally, consider the chemical composition and alloy type to ensure they meet the required specifications for your project. Always procure from suppliers who offer warranties and after-sales support.</p>

- Q: Are there any specific maintenance requirements for aluminum profiles?

- Yes, there are specific maintenance requirements for aluminum profiles. Firstly, regular cleaning is necessary to remove dirt, dust, and other contaminants that may have settled on the surface of the profiles. This can be done using a mild detergent or soap mixed with water and a soft cloth or sponge. Harsh or abrasive cleaners should be avoided as they can damage the protective coating on the aluminum. Secondly, it is important to inspect the aluminum profiles periodically for any signs of damage or wear. This includes checking for dents, scratches, or corrosion. If any damage is found, it should be addressed promptly to prevent further deterioration. Additionally, lubrication may be required for certain moving parts or joints in the aluminum profiles. This can be done using a suitable lubricant or silicone spray, following the manufacturer's recommendations. Furthermore, the protective coating on the aluminum profiles should be inspected and maintained. Over time, this coating may wear off, exposing the aluminum to potential corrosion. In such cases, applying a new coating or protective sealant is recommended to maintain the durability and appearance of the profiles. Lastly, it is important to follow any specific maintenance guidelines provided by the manufacturer of the aluminum profiles. They may have specific recommendations or instructions for cleaning, maintenance, and repair that should be followed to ensure the longevity and performance of the profiles. By following these maintenance requirements, the aluminum profiles can remain in good condition and retain their functionality and aesthetic appeal for a longer period of time.

- Q: Are aluminum profiles fire-resistant?

- Aluminum profiles are commonly acknowledged as being fire-resistant due to their non-combustible nature and inability to ignite or support combustion. Their high melting point of approximately 660 degrees Celsius surpasses typical fire temperatures. Nevertheless, it is crucial to acknowledge that while aluminum itself exhibits fire resistance, the accessories or components utilized alongside aluminum profiles, like gaskets or seals, may not possess the same level of fire resistance. These accessories might possess varying fire ratings, potentially influencing the overall fire resistance of the assembly. In specific scenarios, fire-resistant coatings or treatments can be applied to aluminum profiles to enhance their fire performance. These coatings offer supplementary protection and bolster the fire resistance of the profiles. To ensure fire safety in a particular application, it is always advisable to consult the manufacturer or supplier of the specific aluminum profile. They can provide insights into the profile's fire-resistant properties and suggest additional measures that can be taken to enhance fire safety.

- Q: Ask you, China aluminum plate production factory, supply distribution in the provinces in which the details, please.

- A large share of the domestic market, mainly in Shanghai, Guangdong, Chongqing and other provinces and cities, the other areas are relatively small.From the regional distribution, aluminum production in East China is the highest, followed by South Central China. The provinces and municipalities in Jiangsu, Zhejiang, Guangdong and Chongqing have the highest output.Fengcheng global resource recycling technology development Co., ltd..

- Q: This question asks for an explanation of various methods used to manufacture aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, but also including casting, rolling, and machining. Extrusion is the most common method, where aluminum is heated and forced through a die to create a desired shape. Casting involves pouring molten aluminum into molds to form specific profiles. Rolling is used to produce flat sheets or plates, which can then be further processed. Machining involves cutting and shaping aluminum using tools like lathes and mills. Other processes include forging, which deforms aluminum under high pressure, and powder metallurgy, where aluminum powder is compacted and sintered into a solid profile. Each process has its advantages and is chosen based on the desired profile shape, strength, and application.</p>

- Q: This question asks for a list of various fastening methods used to connect aluminum profiles to the structural frames of buildings.

- <p>There are several types of fasteners used to attach aluminum profiles to building frames, including: 1) Bolts and Nuts: Commonly used for strong, secure connections. 2) Rivets: Provide a permanent connection that is resistant to vibration. 3) Self-Tapping Screws: Can be used in materials without pre-drilling. 4) Structural Glue: Offers a strong bond and is often used in combination with mechanical fasteners. 5) Welding: Used for permanent, load-bearing connections, though not common for aluminum due to the risk of thermal distortion. 6) Clamps and Brackets: Used for temporary or adjustable connections. 7) Adhesive Tapes: Provide a quick and easy method of attachment, though not as strong as other methods. Each type of fastener has its own advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: Can aluminum profiles be used in electrical enclosure manufacturing?

- Certainly, the utilization of aluminum profiles is feasible for the manufacturing of electrical enclosures. Aluminum, being a flexible and lightweight material, presents numerous advantages for such enclosures. Its high conductivity ensures effective dissipation of heat, a vital feature for electronic components that generate heat while functioning. Moreover, aluminum exhibits exceptional resistance to corrosion, guaranteeing that the enclosure can endure even the harshest environmental conditions and prolong its lifespan. In addition, customization and fabrication of aluminum profiles to meet specific design requirements are easily achievable, making them suitable for various enclosure sizes and shapes. All in all, due to their remarkable conductivity, durability, and versatility, aluminum profiles are a favored option for electrical enclosure manufacturing.

Send your message to us

China Aluminum Frame Extrusion Profiles - Large Cross Extrusion Section for Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords