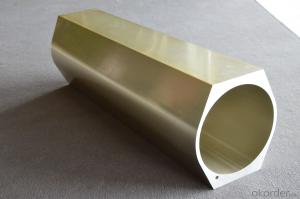

Custom Cina Extruded Aluminum Profiles - Aluminum Profile 003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What are the methods to reduce waste from aluminum profiles in construction?

- <p>To minimize waste generated from using aluminum profiles in building construction, consider the following strategies: 1) Accurate planning and design to reduce offcuts. 2) Utilize modular designs to maximize material usage. 3) Implement recycling programs to repurpose leftover profiles. 4) Opt for suppliers that provide aluminum profiles cut to exact specifications. 5) Educate workers on proper handling and waste reduction techniques. 6) Use digital tools for precise cutting to minimize material waste. 7) Encourage the use of aluminum due to its high recyclability and low energy consumption in the recycling process.</p>

- Q: I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- The price of the equipment is not primary, mainly because of the technical requirements of oxidation. "This is not as simple as you think."

- Q: How about the weight calculation of 180 series semi concealed curtain wall aluminum profile

- A section of properties in CAD labeled dynamic block, the section area and mark block association graph can be easily calculated, section area, surface area, weight theory, and the setting up of a variety of materials such as aluminum options.

- Q: Can aluminum profiles be used for balustrades?

- Yes, aluminum profiles can be used for balustrades. Aluminum is a lightweight and durable material that is commonly used in construction for its strength and resistance to corrosion. It is also easy to shape and work with, making it ideal for creating various designs and styles for balustrades. Additionally, aluminum profiles can be powder coated or anodized to provide a decorative finish and enhance its durability. Overall, aluminum profiles offer a practical and aesthetically pleasing solution for balustrades in both residential and commercial settings.

- Q: How can I distinguish aluminum from aluminium oxide or electrophoresis aluminum or spray aluminium material?

- The electrophoretic material looks very textured, very uniform, and full range. Spray paint will not spray in some places, and the color is not as good as electrophoresis.

- Q: Are aluminum profiles suitable for use in roofing or wall systems?

- <p>Yes, aluminum profiles are commonly used for both roofing and wall systems due to their durability, corrosion resistance, and lightweight properties. They offer a modern aesthetic and can be easily integrated into various architectural designs. Aluminum profiles are also known for their strength and flexibility, allowing for the creation of complex shapes and structures. Additionally, they require minimal maintenance and can withstand harsh weather conditions, making them a popular choice for construction projects.</p>

- Q: This question asks for an enumeration of the various types of aluminum profiles that are commonly utilized in interior wall systems.

- <p>Aluminum profiles for interior wall systems come in various types, each serving a specific purpose. These include: 1. Cover Profiles, which conceal the joints between wall panels; 2. Angle Profiles, used for creating corners and edges; 3. Connecting Profiles, facilitating the attachment of panels; 4. Support Profiles, providing structural support; 5. Joint Profiles, for aligning and securing panels at their joints; 6. Decorative Profiles, adding aesthetic appeal; 7. Insulation Profiles, for thermal insulation; and 8. Sealing Profiles, to prevent air and moisture infiltration. Each type of profile is designed to meet specific architectural and functional requirements, contributing to the overall integrity and appearance of the interior wall system.</p>

- Q: Are aluminum profiles suitable for exterior cladding systems that need to withstand fire?

- <p>Yes, aluminum profiles can be used for exterior cladding systems that require fire resistance. Aluminum is a non-combustible material, which means it does not support combustion. However, it's important to note that while aluminum itself doesn't burn, it can melt at high temperatures. To enhance fire resistance, aluminum profiles can be coated with intumescent paint or used with fire-resistant materials in the cladding system. These measures can help to slow the spread of fire and protect the structure. Always ensure compliance with local building codes and fire safety regulations when selecting materials for fire-resistant applications.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles in the construction of buildings.

- <p>Aluminum profiles in building construction offer several advantages such as high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures, and they are recyclable, contributing to sustainability. Additionally, aluminum profiles can be easily shaped and joined, making them versatile for various architectural designs. However, they also have disadvantages. Aluminum is a good conductor of heat, which can lead to thermal bridging and energy inefficiency if not properly insulated. It can also be more expensive than some traditional materials like steel or wood. Moreover, aluminum's light color can cause glare issues, and it may require additional protective coatings to prevent weathering and maintain its appearance over time.</p>

- Q: How do you clean and maintain aluminum profiles?

- To clean and maintain aluminum profiles, you can follow these simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum profiles using a soft brush or cloth. 2. Prepare a cleaning solution by mixing mild dish soap or a non-abrasive cleaner with warm water. Avoid using harsh chemicals or abrasive cleaners as they can damage the aluminum finish. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum profiles. Be sure to clean all the corners and crevices thoroughly. 4. Rinse the profiles with clean water to remove any soap residue. You can use a hose or a bucket of water for this step. 5. Dry the aluminum profiles completely using a soft, lint-free cloth. This will prevent water spots or streaks from forming. 6. For regular maintenance, you can use a specialized aluminum cleaner or polish to restore the shine and protect the surface. Follow the instructions on the product for best results. 7. It is important to avoid using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Also, never use acidic cleaners or vinegar on aluminum as they can cause corrosion. 8. If you notice any scratches or minor damages on the aluminum profiles, you can use a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Remember, regular cleaning and maintenance will help preserve the appearance and longevity of your aluminum profiles.

Send your message to us

Custom Cina Extruded Aluminum Profiles - Aluminum Profile 003

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords