Aluminum Sheets Houston for Extruded Aluminum Plate in Architectural Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

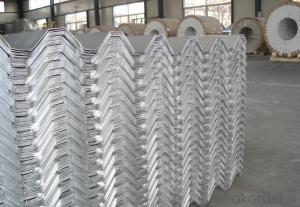

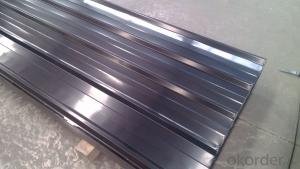

Extruded Aluminum Plate For Architecture Application

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

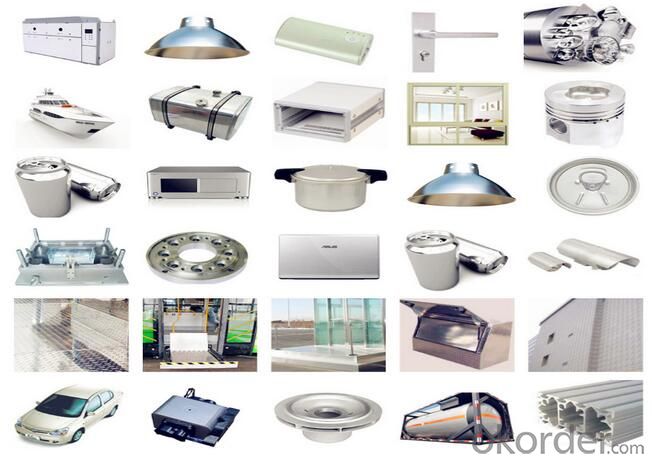

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

Packing

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: Can 101 aluminum sheets be embossed or textured?

- Yes, 101 aluminum sheets can be embossed or textured.

- Q: What is the lifespan of an aluminum sheet?

- The lifespan of an aluminum sheet can vary depending on various factors such as the thickness of the sheet, the quality of the aluminum, and the conditions it is exposed to. However, under normal circumstances, aluminum sheets can last for several decades or even longer if properly maintained and protected from corrosion.

- Q: Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is a versatile and lightweight material that offers several benefits for modular construction projects. It is durable, corrosion-resistant, and has a high strength-to-weight ratio, making it suitable for various structural applications. Aluminum sheets can be easily fabricated and formed into different shapes and sizes, allowing for flexibility in design and construction. Additionally, aluminum is recyclable, making it an environmentally friendly choice for sustainable construction practices. Overall, aluminum sheets are a viable option for modular construction due to their strength, durability, and versatility.

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets possess exceptional water resistance qualities. Thanks to the natural formation of an oxide layer on its surface, aluminum exhibits a high level of resistance to corrosion and effectively hinders water penetration. This oxide layer, referred to as aluminum oxide, acts as a protective barrier, preventing the interaction between aluminum and water molecules. Moreover, aluminum sheets can receive additional surface treatments, such as anodizing or coating, to further enhance their water resistance. These treatments result in a thicker and more durable oxide layer, significantly enhancing the sheets' resistance against water damage, moisture, and rust. In summary, aluminum sheets are a dependable option for applications that necessitate water resistance, guaranteeing enduring performance in diverse environments.

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically refers to the alloy used in their manufacturing. Aluminum alloy 101 is a commercially pure aluminum with a minimum of 99.0% aluminum content. It does not contain any significant amounts of other elements, making it the most basic and pure form of aluminum available. This high purity level makes it highly resistant to corrosion and provides excellent electrical conductivity. 101 aluminum sheets are often used in applications where a high degree of electrical conductivity or corrosion resistance is required, such as in electrical wiring, heat exchangers, and chemical processing equipment.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: Are aluminum sheets suitable for reflective signage?

- Indeed, reflective signage can effectively utilize aluminum sheets. This adaptable material is frequently employed for such signs because of its resilience, lightness, and capacity to reflect light. With a noteworthy reflectivity index, aluminum proves itself ideal for situations where visibility is of utmost importance, such as road signs, traffic signs, and safety signs. By applying reflective films or paints to aluminum sheets, their reflective properties can be further enhanced, guaranteeing optimal visibility even in dimly lit environments. Furthermore, aluminum's resistance to weathering, corrosion, and fading ensures that it remains a durable and economical option for reflective signage in the long run.

- Q: Can aluminum sheets be bent without breaking?

- Aluminum sheets possess the remarkable ability to endure bending without shattering. As a metal, aluminum boasts exceptional malleability and ductility, rendering it effortlessly moldable and pliable. This quality renders aluminum an optimal substance for a wide array of purposes, encompassing the production of aircraft, automobiles, and household articles. The pliability of aluminum sheets facilitates the crafting of intricate designs and intricate forms, establishing it as an exceptionally adaptable substance. It is, nonetheless, worth mentioning that the thickness and caliber of the aluminum sheet may impact its susceptibility to bending. Thicker sheets may necessitate increased force and specialized tools to achieve the desired curvature, whereas softer aluminum grades may yield to bending with greater ease.

- Q: What is the cost of aluminum sheets compared to other materials?

- The cost of aluminum sheets is typically lower compared to other materials such as steel or titanium.

- Q: Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable. Aluminum is a highly recyclable material, and the recycling process for aluminum sheets is relatively simple and efficient. Recycling aluminum sheets involves melting the metal down and reforming it into new sheets or other aluminum products. The recycling process for aluminum requires considerably less energy compared to the production of new aluminum, making it an environmentally-friendly option. Additionally, recycling aluminum sheets helps conserve natural resources and reduces the amount of waste sent to landfills. Therefore, it is encouraged to recycle aluminum sheets whenever possible to contribute to a more sustainable and eco-friendly future.

Send your message to us

Aluminum Sheets Houston for Extruded Aluminum Plate in Architectural Applications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords