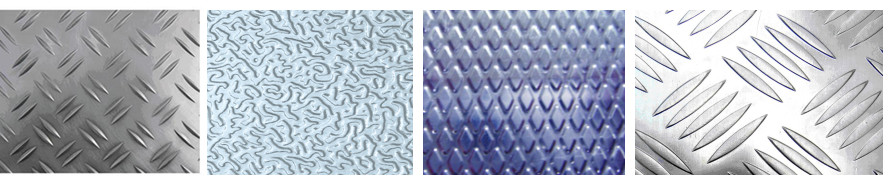

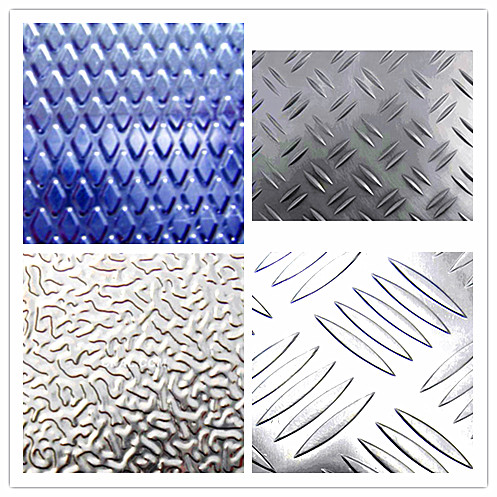

Embossed Aluminum Sheets Houston - Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminumtrade plate have great suctility, heat conductivity, anti-corrosion andmoisture resistance properties.

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754,5083,8011, etc

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm (Can be slitted)

Application:

Anti-slipery purpose in vehicles,packing and appliance, decorative purpose

Business Items

1. Payment: T/T or LC at sight

2. Delivery time: 20 Days

3. Packing:

(1) EPE:protect aluminum.

(2) Plastic sheet:water-proof

(3 )Carton:anti-shock.4 Steel bar:fix

4. Quality: Mill Finish, Totally free from defects like White Rust, Roll Marks, Edge damage , Camber,Dents,Holes,Break Lines, Scratch

Dimensions can be produced according to your specifications,if you need any further details,please be free to tell us,we assure you of our best servieces.

If you are interested in our products, please contact us.

- Q: How does the thickness of aluminum sheet affect its formability?

- The formability of an aluminum sheet is greatly impacted by its thickness. Generally, thinner sheets of aluminum are more easily shaped and are more malleable compared to thicker sheets. This is due to the fact that thinner sheets have less resistance to deformation and require less force to bend or stretch. On the other hand, thicker aluminum sheets have higher resistance to deformation and are less malleable. They necessitate more force and energy to shape, and are more susceptible to cracking or tearing during forming processes. Additionally, thicker sheets are more likely to experience springback, where the material partially returns to its original shape after being formed. The formability of aluminum sheets is also influenced by the specific forming process being used and the alloy composition. In certain cases, specific alloy compositions or heat treatments can enhance the formability of thicker sheets, making them easier to shape. In conclusion, the formability of an aluminum sheet is directly affected by its thickness. Thinner sheets are generally easier to shape and more malleable, while thicker sheets require more force and are less malleable. The alloy composition and specific forming processes being used can also impact the formability of aluminum sheets.

- Q: This aluminum is on a mobile home. I trying to repaint it and there is alot of areas were rust has ate the metal away. Especially in the seams. How can I get rid of the rust that already exists and stop it from coming back.

- Please check with a place like home depot. You could use some steel wool, to get some of the rust off, then paint over tha area with rustoleum. That helps prevent rust, Hope this helps.

- Q: Is it possible to utilize recycled aluminum scraps as an alternative to purchasing new aluminum sheets for a project?

- <p>Yes, you can use recycled aluminum scraps in your project instead of buying new aluminum sheets. Recycled aluminum is not only environmentally friendly but also cost-effective. It has similar properties to new aluminum, making it suitable for many applications. However, ensure the quality and purity of the recycled aluminum meet your project's requirements. Check for any impurities or inconsistencies that might affect the strength or performance of your final product. If the recycled aluminum is in good condition and appropriate for your needs, it can be a sustainable and economical choice.</p>

- Q: Can aluminum sheets be used for heat shields in appliances?

- Yes, aluminum sheets can be used for heat shields in appliances. Aluminum is a lightweight and highly conductive material that can effectively dissipate heat. It has a high melting point and can withstand high temperatures, making it ideal for heat shield applications. Additionally, aluminum is corrosion-resistant, which ensures the durability and longevity of the heat shield. Its flexibility allows for easy installation and shaping to fit different appliance designs. Aluminum sheets are commonly used in various appliances such as ovens, grills, and heating units to protect surrounding areas from excessive heat and prevent potential damage.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity and low density, making it an ideal material for cryogenic applications. It can withstand extremely low temperatures without losing its structural integrity or experiencing significant thermal expansion. Additionally, aluminum has good corrosion resistance and can be easily fabricated into various shapes and sizes. These properties make aluminum sheets commonly used in cryogenic systems, such as cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q: What are the different methods of surface preparation for adhesive bonding of aluminum sheet?

- There are several different methods of surface preparation for adhesive bonding of aluminum sheet. These methods include mechanical abrasion, chemical etching, and surface treatments such as anodizing or conversion coating. Mechanical abrasion involves roughening the surface of the aluminum sheet using sandpaper or other abrasive materials to improve adhesion. Chemical etching involves using acid or alkaline solutions to create a textured surface on the aluminum sheet. Surface treatments such as anodizing or conversion coating involve applying a protective layer or coating to the aluminum sheet to enhance adhesion. Ultimately, the choice of surface preparation method depends on the specific requirements of the adhesive bonding process and the type of adhesive being used.

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- Since Al is more reactive than Cu, no reaction would occur. A reaction would occur only if you had a piece of Al and a solution containing Cu2+ ions. The more active metal replaces the other metal in solution and the less active metal plates out.

- Q: How do aluminum sheets perform in terms of thermal conductivity?

- Aluminum sheets exhibit high thermal conductivity, making them efficient in transferring heat and facilitating heat dissipation.

- Q: does aluminum sheet need to conduct ROHS detection?it's metel material, how much detections should it conduct for ROHS detection?

- generally, all things in Europe needs ROSH EU's requirement, mainly detect the plumbum. ROSH detection is conducted by third party institution, and its report is also provided by the third party.

Send your message to us

Embossed Aluminum Sheets Houston - Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords