High Quality Aluminum Sheets for Sale in Houston - Alloy Aluminum Plate with Orange Peel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Alloy Aluminium Plate with Orange Peel Description:

Alloy Aluminium Plate with Orange Peel are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Alloy Aluminium Plate with Orange Peel:

1)Light

2)Corrosion-resistant

3) The mechanical intensity is high

4) The conducting rate is high

5)The reflecting rate is high.

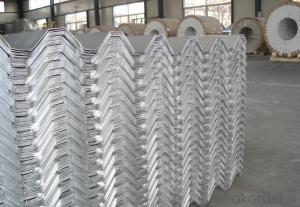

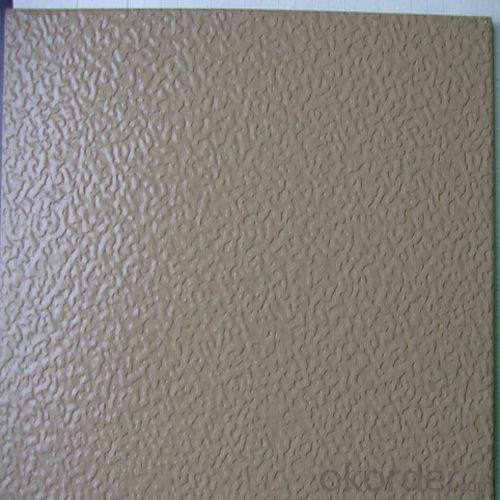

3. Alloy Aluminium Plate with Orange Peel Images:

4. Alloy Aluminium Plate with Orange Peel Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What is the lifespan of aluminum sheets?

- Various factors, such as the aluminum's grade and thickness, the environmental conditions it encounters, and the level of maintenance it receives, can impact the lifespan of aluminum sheets. Aluminum sheets are renowned for their durability and resistance to corrosion, which contributes to their long lifespan. Aluminum possesses natural resistance against rust and corrosion, making it suitable for a wide array of applications. When given proper care and maintenance, aluminum sheets can endure for numerous years. The construction, automotive, and aerospace industries frequently utilize aluminum sheets due to their lightweight nature and robust properties. In outdoor settings, aluminum sheets can withstand harsh weather conditions, including extreme temperatures, humidity, and exposure to UV radiation. Nevertheless, continuous exposure to certain chemicals or corrosive substances can gradually cause damage. To prolong the lifespan of aluminum sheets, it is crucial to regularly clean and safeguard them. This entails eliminating any dirt or debris that might accumulate on the surface and applying protective coatings or treatments as necessary. In conclusion, while it is challenging to provide an exact timeframe for the lifespan of aluminum sheets, they are generally regarded as a long-lasting material that can withstand the test of time when adequately maintained.

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 1. Identification of fluorocarbon spraying and powder spraying aluminum plate:(1) measuring thickness, fluorocarbon three coated with 40UM, and powder coating at least 60UM.(2) surface evenness, fluorocarbon is generally paint, surface smoothness is higher, leveling is better. The powder spraying has poor flatness. Orange peel phenomenon is obvious.(3) look at the back of the workpiece. The back of the workpiece in the transition area of powder coating spraying and spraying, obviously rude sense. And paint is better.(4), the experiment, with a knife or about 400 mesh sandpaper graze back coating, causes the inclined fault. If there are different colors, then fluorocarbon (if not found, you can use a magnifying glass).

- Q: My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q: This question asks for a list of various adhesive types that are suitable for bonding aluminum sheets together.

- <p>There are several types of adhesives used for bonding aluminum sheets, including epoxy adhesives, which are strong and resistant to heat and chemicals; acrylic adhesives, known for their flexibility and UV resistance; cyanoacrylate or super glue, which offers fast bonding; polyurethane adhesives, providing excellent adhesion and durability; and silicone adhesives, which are great for high-temperature applications. Each type has its specific properties and applications, making them suitable for different bonding requirements and environmental conditions.</p>

- Q: What are the different methods of cutting aluminum sheets?

- To cut aluminum sheets, one can utilize various methods based on specific requirements and material thickness. Some commonly employed techniques include: 1. Shearing: By means of a shearing machine, straight lines can be cut in the aluminum sheet. The machine applies force to a blade, resulting in material separation. Shearing is a swift and efficient approach, especially suitable for thinner gauges. 2. Sawing: For cutting aluminum sheets, circular or bandsaws equipped with specialized metal-cutting blades are commonly employed. This method allows for greater precision and controlled cuts, making it ideal for thicker sheets. 3. Laser cutting: This highly precise and efficient technique employs a concentrated beam of light to melt and vaporize the aluminum, resulting in a clean and smooth cut. Laser cutting is particularly advantageous for intricate designs and complex shapes. 4. Waterjet cutting: This method involves the use of a high-pressure stream of water mixed with abrasive particles to cut through aluminum sheets. It is applicable to various thicknesses and allows for precise cuts without generating heat. Waterjet cutting is often preferred for thicker sheets or when high precision is required. 5. Plasma cutting: By employing a high-temperature plasma torch, aluminum sheets can be melted and cut. The torch generates an electric arc, ionizing the gas and creating a plasma state. Although versatile and capable of cutting through different thicknesses, plasma cutting may yield rougher edges in comparison to laser or waterjet cutting. When selecting the most suitable method for cutting aluminum sheets, it is crucial to consider project-specific requirements such as desired cut quality, speed, and complexity.

- Q: I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q: What is the thickness range available for aluminum sheets?

- The thickness range available for aluminum sheets typically varies from 0.006 inches (0.15mm) to 0.25 inches (6.35mm), depending on the specific requirements and application.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets have excellent fire-resistant properties due to their high melting point, which is around 660°C (1220°F). They do not burn or release any harmful gases when exposed to fire. Additionally, the oxide layer that forms naturally on the surface of aluminum provides further protection against fire by acting as a barrier that prevents the metal from direct contact with flames.

- Q: Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

Send your message to us

High Quality Aluminum Sheets for Sale in Houston - Alloy Aluminum Plate with Orange Peel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords