Aluminum T Slot Extrusion Profiles in Alloy 6063, 6061 with Temper T5, T6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable.

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5-6 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

Products are exported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam, Nigeria etc, over 100 countries and regions all over the world.

1. Application of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

2. Feature of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

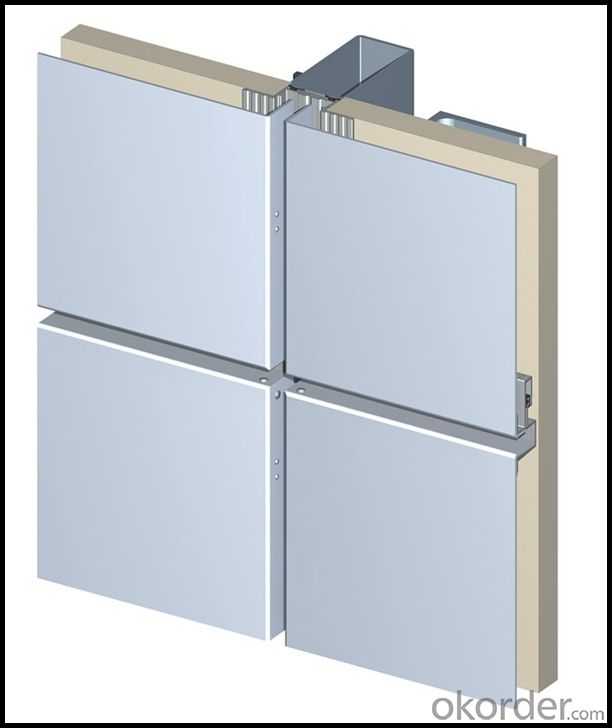

4. Image of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

5. Package and shipping of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: Industrial aluminum profiles are generally used in what industry?

- Kunshan Austrian crown aluminum to tell you: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, electronic machinery industry and clean room with.

- Q: What is the thickness of the aluminum alloy window frame?

- According to the GB / T5237 Aluminum Alloy "building materials" regulations, construction aluminum minimum nominal wall thickness should be not less than 1.2mm, wherein the solid profile wall thickness error of 0.15mm, namely the wall thickness not less than 1.05mm; hollow profile parts containing a closed cavity wall thickness allowance of 0.23mm, the wall thickness is not lower than 0.97mm.

- Q: What tests do the aluminum profiles used in the curtain wall project do?

- Accessories and fasteners for 3.2.5 and glass curtain wall shall meet the requirements of the following current national standards:"Land spring" GB / T9296"Aluminum Alloy flat open window handle" GB / T9298"Aluminium alloy window, stainless steel slide", GB / T 9300"Aluminum alloy door bolt" GB / T9297"Aluminum alloy window block" GB / T9299"Aluminum alloy door and window handle" GB / T9301"Aluminum alloy window lock" GB / T9302"Aluminum alloy door lock" GB / T9303Door closer, GB / T9305Pulley for sliding aluminium alloy doors and windows GB / T 9304Fasteners, bolts and screws, GB / T 5277"Cross slot screw" GB / T 818Mechanical properties of fasteners - Bolts, screws and studs - GBfT 3098.1Fasteners, mechanical properties, nuts, coarse thread, GB / T 3098.2Fasteners, mechanical properties, nuts, fine thread, GB / T 3098.4Fasteners, mechanical properties, bolts, tapping screws, GB / T 3098.5"Fasteners, mechanical properties, stainless steel bolts, screws and studs" GB / T 3098.6Fasteners, mechanical properties, stainless steel nuts, GB / T 3098.15

- Q: Can aluminum profiles be used in modular construction?

- Indeed, modular construction can indeed utilize aluminum profiles. Possessing qualities such as being lightweight, sturdy, and long-lasting, aluminum profiles prove to be an optimal selection for modular construction endeavors. They can be effortlessly shaped and sized, thus allowing for flexibility in both design and construction. Moreover, aluminum profiles exhibit exceptional resistance against corrosion, a pivotal trait for modular structures that may face adverse weather conditions. Furthermore, the utilization of aluminum profiles in modular construction provides benefits such as reduced construction time, cost-effectiveness, and sustainability, given that aluminum is highly recyclable. In summary, aluminum profiles offer a dependable and efficient solution for modular construction projects.

- Q: Is it possible to recycle aluminum profiles and repurpose them for different uses?

- <p>Yes, aluminum profiles can be recycled and reused in other applications. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for a variety of new applications, such as construction, automotive, and consumer goods. The recycling of aluminum profiles not only conserves resources but also reduces waste and environmental impact.</p>

- Q: This question asks about the various standards and specifications that govern the manufacturing and quality of aluminum profiles.

- <p>Aluminum profiles are governed by a variety of standards and specifications that ensure quality and consistency. These include international standards such as ISO 7599, which specifies tolerances for aluminum profiles, and ASTM B221, which covers aluminum and aluminum-alloy extruded bars, rods, and profiles. National standards like the European EN 573 or the Chinese GB/T 6892 also provide guidelines for aluminum profiles. Specifications cover dimensions, mechanical properties, surface finishes, and tolerances. Each standard may have specific requirements for different types of profiles, such as those used in construction, automotive, or aerospace industries. Compliance with these standards is crucial for ensuring the safety, performance, and reliability of aluminum profiles in various applications.</p>

- Q: Can aluminum profiles be used for furniture?

- Yes, aluminum profiles can be used for furniture. Aluminum is a versatile and lightweight material that is commonly used in the construction of furniture. It offers several advantages, such as being corrosion-resistant, durable, and easy to clean. Aluminum profiles can be used to create various types of furniture, including tables, chairs, shelves, and cabinets. The profiles can be easily customized and shaped to fit specific design requirements. Additionally, aluminum profiles can be powder-coated or anodized to provide a decorative and long-lasting finish. Overall, aluminum profiles are a popular choice for furniture due to their strength, versatility, and aesthetic appeal.

- Q: and I know the meaning of 125MN is 12500 tons. I want to know if 125MN is a English an abbreviation of the word, if it is, then what is he, if he is not that what is the meaning?

- MN is an international unit, said the bull"125MN's extruder is 12500T's extruderBloomberg metal Forum

- Q: Are there any safety considerations when working with aluminum profiles?

- Working with aluminum profiles requires several safety considerations. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) like gloves, safety glasses, and a dust mask. This is necessary because handling aluminum profiles can produce fine metal shavings and dust, which can be harmful if inhaled or come into contact with the skin or eyes. Moreover, ensuring proper ventilation in the work area is essential to reduce the accumulation of aluminum dust and fumes. This can be achieved by utilizing exhaust fans or opening windows and doors to allow fresh air circulation. When cutting or machining aluminum profiles, it is vital to use the correct tools and techniques to prevent accidents or injuries. This includes employing sharp blades or cutting tools specifically designed for aluminum to avoid kickback or other hazards. Additionally, careful handling of aluminum profiles is important as they may have sharp edges or corners that can cause cuts or injuries. It is crucial to use proper lifting techniques to prevent strain or back injuries when moving or installing aluminum profiles. Lastly, being aware of the potential fire hazards associated with aluminum dust is crucial. Aluminum dust is highly flammable and can ignite when exposed to an ignition source like a spark or open flame. Therefore, maintaining a clean work area and regularly removing any accumulated aluminum dust is necessary to minimize the risk of fire. By adhering to these safety considerations and taking necessary precautions, the risks associated with working with aluminum profiles can be minimized, ensuring a safe working environment.

Send your message to us

Aluminum T Slot Extrusion Profiles in Alloy 6063, 6061 with Temper T5, T6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords