Structural Aluminum Profiles for Industrial Material

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile for Industrial Material Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile for Industrial Material :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

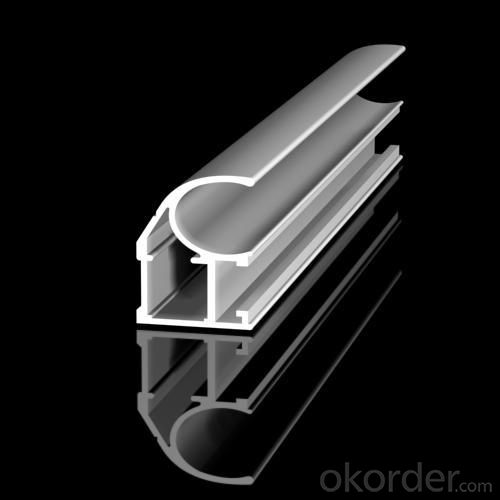

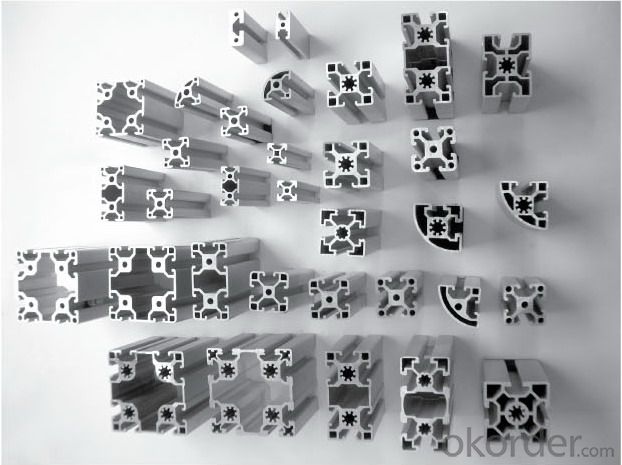

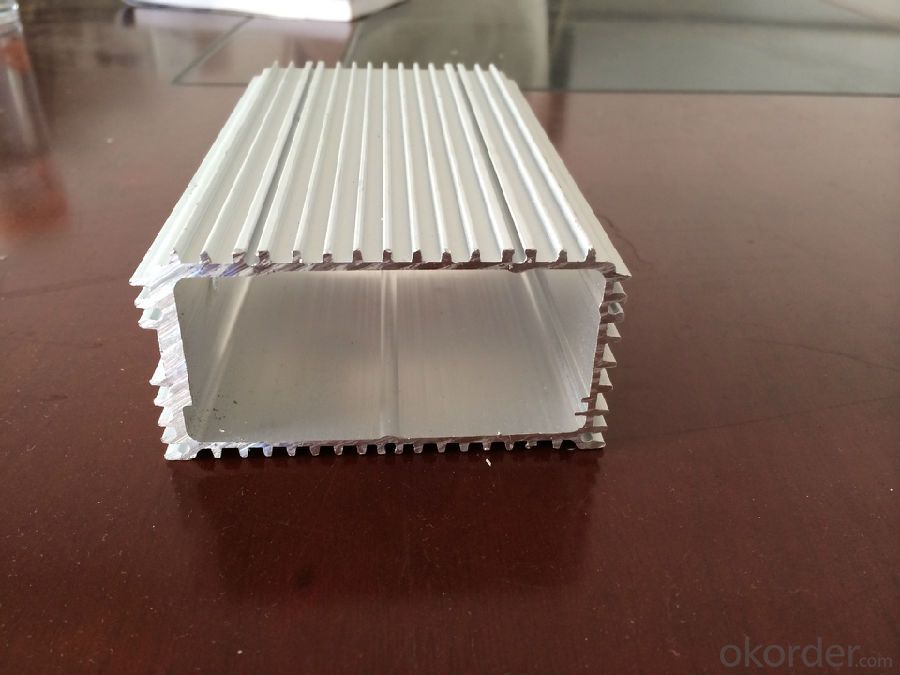

3.Aluminium Profile for Industrial Material Images:

4.Aluminium Profile for Industrial Material Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different surface patterns available for aluminum profiles?

- Aluminum profiles offer a variety of surface patterns, each with unique advantages in terms of appearance and function. The options include: 1. Smooth: This basic pattern features a polished finish, providing a sleek and modern look suitable for applications where aesthetics matter. 2. Brushed: This pattern showcases fine lines or brush strokes in one direction, creating a textured, satin-like appearance popular in contemporary and industrial designs. 3. Anodized: Anodizing is an electrochemical process that results in a durable, corrosion-resistant surface. It can be tailored to achieve different colors and finishes, such as matte, glossy, or metallic. 4. Powder-coated: This technique involves applying dry powder to the aluminum surface, which is then heated to create a smooth and long-lasting finish. It allows for a wide array of colors and textures, including matte, glossy, and textured options. 5. Wood grain: Specialized printing techniques can mimic the look of wood on aluminum profiles. This pattern offers the warm and natural appearance of wood while retaining the durability and low maintenance of aluminum. 6. Textured: Aluminum profiles can also feature a range of textures, from fine sand-like patterns to more pronounced embossed or hammered looks. Textured surfaces not only enhance visual appeal but also provide improved grip and slip resistance. These examples represent just a few of the available surface patterns for aluminum profiles. The choice of pattern depends on specific application requirements, desired aesthetics, and functional needs.

- Q: Where is the aluminum profile market in Tianjin?

- Industrial aluminium profile standard profile:1530156015901640, 2020204020803030, 30R arc, 3030W 3030, 3030R, 3030RQ, 3060309030150, 4040A, 4040Q, 4040L4040W, 4040Z, 40R arc, 40 right angle, 4060Q, 4060L, 4060Z, 4080, 4080L, 4080W, 8080, 8080W, 606080120100100, 1201204012045454545L 4545Q 4545W 45909090 9090W 45R 4560 4560W 501005050501006060 6060L arc 4545RQ (1530-120120 Series) line industrial profiles and accessories can be assembled into processing products: tool rack (car), operation table, special tool cart, line table, product display, LCD panel, sun room, display cabinets, display rack, mechanical seal cover, shelves, product testing equipment, non-standard equipment, industrial fence, plotter, testing equipment, laboratory equipment, biological machine, labeling machine, production line, motor rotor bracket, electronic products production line, production line, line table, equipment protection barrier, LCD panel production equipment

- Q: Can aluminum profiles be custom-designed?

- Indeed, specific requirements and specifications can be catered to when it comes to aluminum profiles. This is because aluminum is an incredibly adaptable and pliable material, which makes it an excellent choice for customization purposes. A wide array of shapes, sizes, and configurations can be achieved when creating custom-designed aluminum profiles, ensuring they meet the unique demands of various industries and applications. The customization process often entails seeking guidance from experts who possess the expertise and know-how to design and manufacture aluminum profiles that align with the desired specifications. By opting for custom-designed aluminum profiles, one can benefit from their precise dimensions, distinctive shapes, and enhanced functionality, guaranteeing an impeccable fit for any given project.

- Q: This question asks for a comparison of aluminum profiles with other materials regarding their weight and strength characteristics.

- <p>Aluminum profiles are known for their high strength-to-weight ratio, making them lighter than many other materials while maintaining significant strength. Compared to steel, aluminum is approximately one-third the weight but offers comparable strength, especially in alloy forms. When compared to plastics, aluminum profiles have greater rigidity and durability. They also resist corrosion and are more heat resistant than many plastics. However, aluminum profiles are generally more expensive than plastics and some steels. In summary, aluminum profiles offer a balance of low weight and high strength, making them suitable for applications where weight savings and structural integrity are crucial.</p>

- Q: Are aluminum profiles resistant to mold or mildew?

- Yes, aluminum profiles are resistant to mold or mildew.

- Q: What are the different sizes and dimensions of aluminum profiles?

- Various industrial and construction needs can be met with aluminum profiles, which are offered in a wide range of sizes and dimensions. These profiles are available in different shapes, including angles, channels, beams, tubes, and bars, each with its own unique dimensions. Angle profiles, for example, can be found in sizes ranging from 1/2 inch to 6 inches, with thickness measurements that vary from 1/16 inch to 1/2 inch. These profiles are commonly utilized for structural applications, reinforcements, and framing. For channel profiles, dimensions range from 1/2 inch to 8 inches, with thickness measurements varying between 1/8 inch to 1/2 inch. These profiles are often used for framing, support structures, and edge protection. Beam profiles have varying dimensions, including heights that range from 1 inch to 12 inches and flange widths from 1 inch to 6 inches. The thickness of these profiles can range from 1/8 inch to 1/2 inch. Beam profiles are frequently employed for load-bearing applications, such as bridges, buildings, and heavy machinery. Tube profiles come in various sizes, including outer diameters ranging from 1/2 inch to 12 inches and wall thicknesses between 1/16 inch to 1/2 inch. These profiles are commonly utilized in applications requiring fluid transportation, structural support, and decorative purposes. Lastly, aluminum bars are available in different dimensions, such as widths ranging from 1/8 inch to 6 inches and heights from 1/8 inch to 2 inches. The thickness of these bars can vary from 1/8 inch to 1/2 inch. Aluminum bars are commonly used for structural support, framing, and decorative purposes. It is important to keep in mind that these dimensions are not exhaustive and may vary based on the manufacturer and specific project requirements. It is recommended to consult with the manufacturer or supplier to determine the exact sizes and dimensions available for a specific aluminum profile.

- Q: What are the anti-static properties of aluminum profiles?

- Due to their inherent electrical conductivity, aluminum profiles exhibit exceptional anti-static properties. This unique feature enables them to effectively dissipate static charges and prevent the build-up of static electricity. Consequently, aluminum profiles find widespread use in various industries, including electronics, automotive, aerospace, and manufacturing. In these sectors, they serve multiple purposes such as supporting conveyor systems, providing protective enclosures, and serving as grounding components. By minimizing the dangers associated with static electricity, such as electrostatic discharge (ESD) damage, fire risks, and interference with delicate electronic devices, the anti-static qualities of aluminum profiles guarantee safe and dependable operations.

- Q: What specific criteria or standards must be met when utilizing aluminum profiles in the construction of environmentally friendly buildings?

- <p>In green building construction, aluminum profiles must meet certain sustainability and environmental requirements. These include high recyclability to reduce waste, low embodied energy to minimize environmental impact during production, and adherence to standards like LEED certification. Profiles should also be durable and low-maintenance to reduce the need for replacement and associated waste. Additionally, the use of eco-friendly coatings and finishes that do not release harmful substances is crucial. Compliance with regional green building codes and regulations is also mandatory.</p>

- Q: This question asks for the various types of paint that can be used to protect aluminum profiles from weathering.

- <p>Aluminum profiles can be protected from weathering through the application of different types of paints. These include: 1) Powder Coating, which provides a durable and weather-resistant finish. 2) Anodizing, a process that increases the thickness of the natural oxide layer on aluminum, enhancing its resistance to corrosion. 3) Liquid Coatings, such as acrylic or polyester-based paints, which offer a range of colors and finishes. 4) Fluorocarbon Paints, known for their excellent resistance to UV rays and weathering. Each type has its own advantages and is chosen based on the specific requirements for durability, appearance, and environmental conditions.</p>

- Q: What kind of equipment are needed for the production of aluminum profiles?

- The production of aluminum equipment not hundreds of several decades, from the beginning, homogeneous casting furnace, extrusion machine, anodic electrophoretic coating production line groove, powder powder production line, fluorocarbon paint production line, insulated aluminum production line, processing workshop welding riveting, stitching and other processing equipment. Plus to die do I still have, cars, milling, grinding, drilling, EDM, wire cutting, and other processing equipment. I am now in a small department work of aluminum processing company.

Send your message to us

Structural Aluminum Profiles for Industrial Material

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords