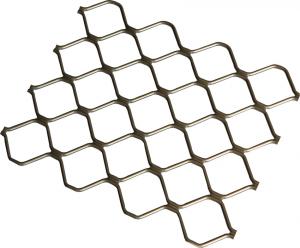

Aluminum Grills Mesh Moulding Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminum mesh

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What is the material content of 4040 aluminum alloy profiles?

- 40*40 aluminum profile, commonly known as industrial aluminum, aluminum assembly line, table, aluminum profiles. The material content of silicon (Si) 0.2-0.6% (Fe) 0.35%, iron and copper (Cu) 0.1% (Mn 0.1%), manganese and magnesium (Mg), 0.45-0.9% (Cr) 0.1% chromium and zinc (Zn) 0.1%, titanium (Ti) 0.1%, other metals accounted for the total proportion of 0.15%, aluminum (Al 97.35--98.35%).

- Q: What are the different colors and finishes available for aluminum profiles?

- There are various colors and finishes available for aluminum profiles, allowing for customization and versatility in design. Some common colors include silver, black, white, bronze, and gold. These colors can be achieved through anodizing, which involves the electrochemical process of creating a durable oxide layer on the surface of the aluminum. Anodized finishes not only provide color options but also enhance the corrosion resistance and durability of the profiles. Apart from anodizing, powder coating is another popular method used to achieve different colors and finishes. Powder coating involves applying a dry powder to the aluminum surface electrostatically, and then curing it under heat to create a smooth, strong, and uniform finish. This method offers a wide range of colors, including metallic, matte, gloss, and textured finishes. Furthermore, aluminum profiles can also be painted using liquid paint, which provides endless color options. Liquid paint finishes can be customized to match specific color requirements, making them ideal for projects with unique design needs. In summary, the different colors and finishes available for aluminum profiles include anodized finishes such as silver, black, white, bronze, and gold, as well as powder coating finishes like metallic, matte, gloss, and textured. Additionally, liquid paint can be used to achieve virtually any color desired. These options allow for flexibility in design and ensure that aluminum profiles can complement various architectural and industrial applications.

- Q: Can aluminum profiles be used for electrical cabinets?

- Indeed, electrical cabinets can employ aluminum profiles. Aluminum, a material that is both lightweight and sturdy, exhibits outstanding electrical resistance and thermal conductivity. Its durability and efficient heat dissipation make it a frequent choice for electrical cabinets. Aluminum profiles provide a robust structure for these cabinets, facilitating the effortless installation of wiring and electrical components. Moreover, aluminum profiles can be readily tailored and modified to meet precise design specifications, rendering them an optimal selection for electrical cabinets.

- Q: This question asks about the various uses of aluminum profiles in the construction of buildings.

- <p>Aluminum profiles have a wide range of applications in building construction due to their strength, durability, and lightweight properties. They are used in window and door frames, curtain walls, and structural glazing systems for their high strength-to-weight ratio and resistance to corrosion. Additionally, aluminum profiles are utilized in the construction of balconies, handrails, and stairways for their ability to withstand harsh weather conditions. They are also employed in the fabrication of modular building systems and prefabricated components, offering ease of assembly and design flexibility. Furthermore, aluminum profiles are used in the construction of solar panel mounting systems and facades due to their thermal conductivity and ability to support heavy loads.</p>

- Q: Are aluminum profiles suitable for cleanroom partitions?

- Yes, aluminum profiles are often suitable for cleanroom partitions. Aluminum is a lightweight and durable material that is resistant to corrosion, making it a popular choice for cleanroom applications. It is easy to clean and maintain, which is crucial in maintaining the cleanliness and sterility of a cleanroom environment. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility in designing cleanroom partitions to meet specific requirements. The versatility of aluminum profiles also enables the integration of various features such as doors, windows, and pass-through chambers, further enhancing the functionality of cleanroom partitions. Overall, with their excellent properties and adaptability, aluminum profiles are a reliable and suitable choice for cleanroom partitions.

- Q: Is it possible to use aluminum profiles as materials for flooring?

- <p>Aluminum profiles can indeed be used for flooring materials, particularly in industrial or commercial settings. They are valued for their strength, durability, and resistance to corrosion. Aluminum profiles are often used in modular flooring systems, providing a stable and customizable base that can be easily adjusted or reconfigured. They are also appreciated for their lightweight nature, which can reduce the load on structures and facilitate installation. However, for residential applications, traditional flooring materials like wood, tile, or carpet are more common due to aesthetic and comfort considerations.</p>

- Q: How do aluminum profiles contribute to water management strategies?

- Aluminum profiles contribute to water management strategies by being used in the construction of water tanks, pipes, and fittings. These profiles have excellent corrosion resistance and durability, making them ideal for storing and transporting water. Additionally, their lightweight nature allows for easy installation and maintenance. Overall, aluminum profiles play a crucial role in ensuring efficient water management systems by providing reliable and long-lasting infrastructure.

- Q: Can aluminum profiles be utilized in high-rise constructions that incorporate large windows?

- <p>Yes, aluminum profiles are commonly used in high-rise buildings with large windows due to their strength, durability, and lightweight properties. They offer excellent resistance to corrosion and weathering, making them ideal for external applications. Additionally, aluminum profiles can be easily customized to fit various window designs and sizes, providing both aesthetic and functional benefits. Their thermal break technology also helps in reducing heat transfer, enhancing energy efficiency in buildings.</p>

- Q: What are the differences between aluminium profiles 6063 and 6463?

- Mg and Si are the main alloying elements. The main work of optimizing chemical composition is to determine the percentage content of Mg and Si (mass fraction, the same below).1.1 the role of Mg and effects of Mg and Si Mg2Si phase Mg, the higher the content of Mg2Si, the number is more, the greater the effect of heat treatment, the tensile strength of the material was higher, but the deformation resistance increases, the ductility of the alloy decreased, processing performance is bad, bad corrosion resistance.

- Q: This question asks about potential health hazards related to the use of aluminum profiles in construction.

- <p>There are minimal health risks associated with using aluminum profiles in building construction. Aluminum is a non-toxic metal and does not emit harmful substances. However, during the manufacturing process, if not properly controlled, there might be concerns related to dust and fumes. Additionally, aluminum can react with other materials, potentially causing corrosion or weakening the structure. It's important to ensure that aluminum profiles are used in accordance with safety standards and guidelines to mitigate any potential risks.</p>

Send your message to us

Aluminum Grills Mesh Moulding Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords