Grp Lamination

Grp Lamination Related Searches

Grp Pipe Lamination Grp Reinforced Plastic Grp Reinforcement Grp Roofing Prices Grp Flange Cold Lamination Grp Pipe Full Form Composite Grp Grp Glass Reinforced Polyester Amiantit Grp Pipes Frp And Grp Graphite Corrosion Resistance Outdoor Hpl Laminate Exterior Grade Laminates Garage Laminate Flooring Glossy Laminate Countertops Deflection Test For Grp Pipes Galvanized Steel Grating Compacted Graphite Iron Hot Dip Galvanizing Painted Galvanized Steel Galvanized Steel Paint Galvanized Steel Roof Gf Ppr Pipe Frp Pultrusion Galvanized Steel Siding Frp Roof Rusting Galvanized Steel Galvanized Steel Piping Galvanized Steel Roof PanelGrp Lamination Supplier & Manufacturer from China

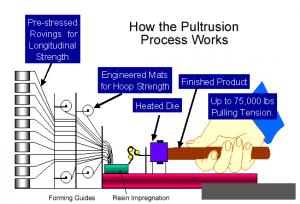

Grp Lamination refers to the process of applying a glass reinforced plastic (GRP) layer to various products, enhancing their durability and resistance to harsh environmental conditions. This technique is widely used in the manufacturing of pipes, tanks, and other industrial equipment, providing them with increased strength and a longer lifespan. The GRP layer acts as a protective barrier, shielding the underlying material from corrosion, wear, and tear, making it an ideal choice for applications in industries such as chemical processing, water treatment, and construction.The application and usage scenarios for Grp Lamination products are vast, as they are designed to withstand the demands of various industrial settings. These products are commonly utilized in the transportation of chemicals, storage of hazardous materials, and construction of infrastructure projects. Their versatility and robustness make them a popular choice for companies seeking reliable and long-lasting solutions for their operations. The GRP layer not only protects the product from external factors but also contributes to its overall performance and efficiency.

Okorder.com is a leading wholesale supplier of Grp Lamination products, boasting a large inventory that caters to the diverse needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that their Grp Lamination products meet the highest standards of durability and performance. By offering a wide range of options, Okorder.com enables customers to find the perfect Grp Lamination solution for their specific requirements, making them a trusted partner for businesses in search of reliable and cost-effective products.

Hot Products