Cheapest Aluminum Prepainted Coil for Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted in Coil Form for Roofing Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted in Coil Form for Roofing:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

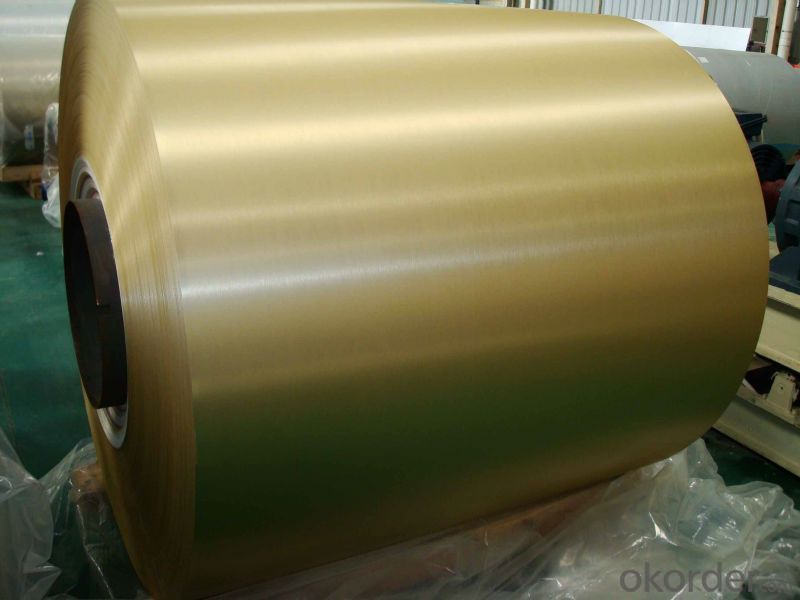

Images of the Aluminium Prepainted in Coil Form for Roofing:

Aluminium Prepainted in Coil Form for Roofing Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepainted in Coil Form for Roofing:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the different types of surface treatments available for anodized aluminum sheets?

- There are several different types of surface treatments available for anodized aluminum sheets. These treatments can enhance the appearance, durability, and functionality of the aluminum surface. 1. Brushed Finish: This treatment involves brushing the surface of the aluminum sheet with abrasive materials to create a pattern of parallel lines. It gives the sheet a matte appearance and helps to hide scratches and fingerprints. 2. Mirror Finish: In this treatment, the aluminum sheet is polished to a high gloss finish, creating a mirror-like reflection. This finish is commonly used in decorative applications and gives a sleek and modern look to the aluminum surface. 3. Etched Finish: Etching involves using chemicals or abrasive materials to remove a thin layer of the anodized coating from the aluminum surface. This creates a textured or patterned design on the sheet. Etching can be done in various depths and designs, allowing for customization and unique aesthetics. 4. Powder Coating: Powder coating is a popular surface treatment where a dry powder is electrostatically applied to the anodized aluminum sheet and then cured under heat. This creates a durable and resistant coating that can be customized in terms of color, texture, and finish. 5. Satin Finish: Satin finish involves sanding the aluminum sheet with fine grit sandpaper to create a smooth, brushed appearance. It provides a subdued and elegant look to the aluminum surface. 6. Mechanical Finishes: Mechanical finishes include various techniques like polishing, buffing, or grinding to achieve different surface textures and finishes. These finishes can range from smooth and glossy to rugged and textured, depending on the desired effect. 7. Chemical Treatments: Chemical treatments such as anodizing, chromating, or chemical brightening can be used to enhance the corrosion resistance, color, and overall appearance of the aluminum sheet. These treatments can also improve the adhesion of paints or adhesives to the surface. It is important to note that the availability of these surface treatments may vary depending on the manufacturer and specific requirements. It is recommended to consult with the supplier or manufacturer to determine the most suitable surface treatment for your application.

- Q: What are the different methods of forming aluminum sheets?

- There are several methods of forming aluminum sheets, including rolling, extrusion, and stamping. Rolling involves passing the aluminum through a series of rollers to reduce its thickness and create a uniform sheet. Extrusion involves pushing the aluminum through a die to create a specific shape or profile. Stamping involves using a mold or die to press the aluminum into a desired shape or pattern.

- Q: i know the 4100 is aluminum........im wondering if this one is also..

- Aluminum Block Cast Iron Heads !!!! with floating cast iron cylinder sleaves...

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are various types of alloys used for powder-coated aluminum sheets, including 3003, 5052, and 6061.

- Q: How do you form curves or shapes in aluminum sheets?

- There are several methods to form curves or shapes in aluminum sheets. One common technique is called bending, where the sheet is clamped and then gradually bent using a mechanical press brake or a hammer. Another method is called roll forming, which involves passing the aluminum sheet through a series of rollers to achieve the desired shape. Additionally, aluminum sheets can be molded or pressed into curves or shapes using specialized tools or dies.

- Q: I think I remember that this is true of aluminum foil. When it's charged, it'll push away from itself, I know. Why do magnets have seemingly no effect?

- Aluminum is a non-ferrous metal. Ferrous metals contain Iron which is magnetic. When aluminum has a charge applied to it, it acts like any conductor would, the charge has magnetic properties. the aluminum is still not magnetic, but it acts like a magnet due to the charge.

- Q: Are aluminum sheets suitable for chemical processing equipment?

- Under certain conditions, chemical processing equipment can utilize aluminum sheets. Aluminum demonstrates good resistance to a variety of chemicals, including acids and alkalis. It exhibits exceptional resistance to corrosion in acidic surroundings like hydrochloric acid and sulfuric acid, as well as alkaline solutions such as sodium hydroxide. However, it is crucial to acknowledge that aluminum is not universally suitable for all chemical processes. It is not advisable to employ it in applications involving potent oxidizing agents like nitric acid or chromic acid, as these substances can swiftly corrode aluminum. In addition, aluminum is incompatible with certain organic solvents and can react with them, leading to equipment degradation or malfunction. In certain situations, aluminum can be employed in chemical processing equipment by employing protective coatings or linings to bolster its resistance against specific chemicals. This approach can enhance its longevity and broaden its range of applications. In conclusion, although aluminum sheets can be appropriate for chemical processing equipment in numerous cases, it is imperative to carefully evaluate the specific chemicals and operating conditions involved to ensure compatibility and steer clear of potential corrosion or malfunction issues.

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

- Q: What is the weight of aluminum sheets?

- The weight of aluminum sheets can vary depending on their thickness and dimensions. However, on average, aluminum sheets typically weigh around 2.7 grams per cubic centimeter.

- Q: Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile and efficient method that can be used to cut through a wide range of materials, including aluminum.

Send your message to us

Cheapest Aluminum Prepainted Coil for Roofing Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords