Aluminum Prepainted Aluminum Coil for Roller Shutter - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of ACP Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

Main Features of ACP:

1) Super werther resistance

2) Light weight easy to process

3) Excellent fire resistance

4) Excellent impact strength

5) Uniform and colorful coating

6) Easy maintenance...and so on

7) Within 15 work days after receiving the first deposite payment .

Images of ACP:

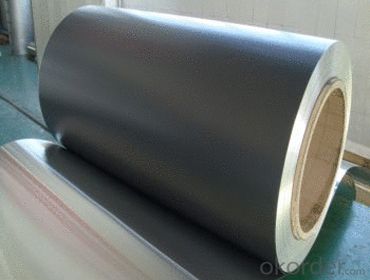

Structure of Aluminium Coated Coil Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

Advertisement: display platforms, signboards, fascia, shop fronts...

Main Features of the Aluminium Coated Coil:

Enviromental, light weight, waterproof, fireproof, anti-rust, weather resistance, easy cleaning, easy matching with other decoration materials...

Images of Aluminium Coated Coil:

Aluminium Coated Specifications:

| Item | Test Item | Standard | National standard | DF Test Result |

| 1 | Color Difference | ECCA T3 | Δ E≤ 2.0 | Δ E≤ 1.5 |

| 2 | Gloss Difference | ECCA T2 | ≤ 10 | ≤ 5 |

| 3 | Coating Thickness | ECCA T1 | Two layers Min 23um | ≥ 24um |

| Three layers Min 30um | ≥ 33um | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥ HB | HB |

| 5 | T-bend | ASTM D4145 | ≤ 2T | ≤ 2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≥ 50 kg/cm | ≥ 50 kg/cm |

| 8 | Boiling water Resistance | GB/T17748 | 2h No Change | 4h No Change |

| 9 | Solvent Resistance | ASTM D2248 | 200 times paints remaining | 500 times no break |

| 10 | Acidity Resistance | ASTM D1308 | 5%HCL 24hrs no change | No change |

| 11 | Alkali Resistance | ASTM D1308 | 5%NaOH 24hrs no change color Δ E≤ 2.0 | No change |

| 12 | Nitric acid Resistance | AAMA620 | Δ E≤ 5.0 | Δ E≤ 5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20# oil 24hrs no change | No change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs≤ Grade 1 | No change |

| 15 | Abrasion resistance | ASTM D968 | ≥ 5L/um | ≥ 5L/um |

| 16 | Dirt Resistance | GB/T9780 | ≤ 5% | < 5% |

| 17 | Color retaining | GB/T16259 | 4000 hrsΔ E≤ 4.0 | 4000 hrsΔ E≤ 3.0 |

| 18 | Gloss weaken Level | GB/T16259 | 4000 hrs ≤ Grade 2 | 4000 hrs ≤ Grade 2 |

FAQ of Aluminium Coated Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

ACP Specifications:

Standard size | 1220*2440*3mm and 1220*2440*4mm |

Accepted Width | Max:1580mm |

Accepted Length | Max:6000mm |

Accepted Thickness | 2mm,3mm,4mm,5mmm,6mm |

Aluminum alloy thickness | 0.10mm0.15mm0.18mm0.21mm0.25mm0.3mm0.35mm0.40mm0.45mm0.50mm |

Weight | 5 kg/m2 base on 4*0.4mm |

Nonstandard | sizes are available according your requirement |

FAQ of ACP:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks about the impact of aluminum on human health.

- <p>Aluminum is a naturally occurring element that can be found in small amounts in various foods, water, and air. While it's not considered an essential nutrient, it's also not inherently harmful in small quantities. However, excessive exposure to aluminum has been linked to potential health concerns. Some studies suggest that high levels of aluminum might contribute to neurological disorders, particularly Alzheimer's disease, although the evidence is not conclusive. Aluminum can also cause digestive issues and bone disorders if ingested in large amounts. It's important to note that the human body does not absorb aluminum efficiently, and most ingested aluminum is excreted without issue. However, it's always advisable to minimize exposure to high levels of aluminum, especially for vulnerable populations such as infants and those with kidney issues.</p>

- Q: This question asks about the chemical reactions of aluminum with acids and alkalis under various conditions.

- <p>Aluminum reacts differently with acids and alkalis depending on the specific environment. In the presence of acids, such as hydrochloric or sulfuric acid, aluminum undergoes a redox reaction where it loses electrons and forms aluminum ions (Al^3+). The reaction can be represented as: 2Al + 6HCl 鈫?2AlCl鈧?+ 3H鈧? With alkalis, aluminum reacts to form aluminate ions and hydrogen gas. This reaction is represented as: 2Al + 2NaOH + 6H鈧侽 鈫?2NaAl(OH)鈧?+ 3H鈧? The rate of these reactions can be influenced by factors such as temperature, concentration, and the presence of catalysts.</p>

- Q: Is it possible to employ aluminum for the creation of innovative packaging materials?

- <p>Yes, aluminum is highly suitable for making new types of packaging materials due to its lightweight, malleability, and corrosion resistance. It is often used in food and beverage cans, pharmaceutical packaging, and even flexible packaging films. Aluminum's recyclability also makes it an environmentally friendly choice for sustainable packaging solutions. Innovations in aluminum packaging continue to emerge, focusing on improved barrier properties, lighter weight, and enhanced recycling capabilities.</p>

- Q: Is it possible to utilize recycled aluminum in the manufacturing of automobiles and other types of vehicles?

- <p>Yes, recycled aluminum can be used to make automobiles and other vehicles. It is a common practice as aluminum is highly recyclable and retains its properties even after multiple recycling processes. Using recycled aluminum reduces the need for new aluminum production, which is energy-intensive, and contributes to sustainability efforts. Recycled aluminum is often used in vehicle components such as engine parts, body panels, and wheels, due to its lightweight, strength, and corrosion resistance.</p>

- Q: Is there a connection between aluminum exposure and the development of Alzheimer's disease?

- <p>Aluminum has been a subject of debate regarding its potential link to Alzheimer's disease. However, current scientific consensus does not support the idea that aluminum exposure causes Alzheimer's. Extensive research has failed to establish a definitive causal relationship between aluminum and Alzheimer's. While aluminum is naturally present in the environment and can be found in some foods, water, and medications, studies have not shown it to be a significant risk factor for the development of Alzheimer's. The disease is believed to be caused by a combination of genetic, lifestyle, and environmental factors, but aluminum is not considered one of them.</p>

- Q: Is there any health risk associated with using pure aluminum cookware?

- <p>Using pure aluminum cooking utensils is generally considered safe for most people. However, there are some concerns regarding the potential for aluminum to leach into food, especially at high temperatures or with acidic foods. While the health risks are still a subject of debate, it's recommended to use aluminum cookware with a protective coating or opt for utensils made from other materials like stainless steel or cast iron for long-term health considerations.</p>

- Q: What are the differences between Aluminum Oxide and Aluminum Alloy in terms of their properties and applications?

- <p>Aluminum Oxide and Aluminum Alloy are distinct materials with different properties and uses. Aluminum Oxide, also known as alumina, is a ceramic material with a high melting point, hardness, and electrical insulation properties. It's used in abrasives, electronics, and as a refractory material. In contrast, Aluminum Alloys are composites of aluminum with other elements like copper, magnesium, or silicon, which enhance their strength, corrosion resistance, and malleability. They are widely used in construction, automotive, aerospace, and packaging due to their lightweight and durability.</p>

- Q: Is it safe to use aluminum containers for food and drink in a microwave?

- <p>Aluminum is not recommended for use in microwave-safe containers for food and drink. While some aluminum containers are designed to be microwave-safe, they are typically coated with a non-metallic material to prevent arcing and damage to the microwave. However, most aluminum containers are not safe for microwave use as they can cause sparks and potentially damage the microwave. It's best to use microwave-safe plastics, glass, or ceramics specifically designed for microwave use.</p>

- Q: This question asks about the typical applications of aluminum pipes in various industries and settings.

- <p>Aluminum pipes are commonly used in a variety of applications due to their lightweight, corrosion resistance, and high thermal conductivity. They are extensively used in the automotive industry for parts like radiators and heat exchangers. In construction, aluminum pipes are utilized for heating, ventilation, and air conditioning (HVAC) systems. They are also used in the beverage industry for conveying and cooling liquids, as well as in the aerospace industry for fuel and hydraulic lines due to their strength-to-weight ratio. Additionally, aluminum pipes are found in industrial settings for compressed air and gas lines, and in marine applications for fuel and water systems.</p>

- Q: This question asks about the impact of heat on the characteristics of aluminum, including its physical and chemical properties.

- <p>Heat significantly affects the properties of aluminum. As temperature increases, aluminum's electrical and thermal conductivity decrease, although it remains a good conductor. Its strength and hardness also decrease with rising temperature, which can lead to reduced structural integrity in high-temperature applications. Thermal expansion occurs, causing the metal to lengthen and potentially deform. Aluminum's malleability and ductility increase with heat, making it easier to shape and form. However, prolonged exposure to high temperatures can cause oxidation and corrosion. The specific heat treatment, such as annealing or quenching, can also alter aluminum's microstructure, impacting its mechanical properties.</p>

Send your message to us

Aluminum Prepainted Aluminum Coil for Roller Shutter - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords