Prepainted Aluminum Coil for Sale - 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluminium Coil 1060 3003 3105 Description:

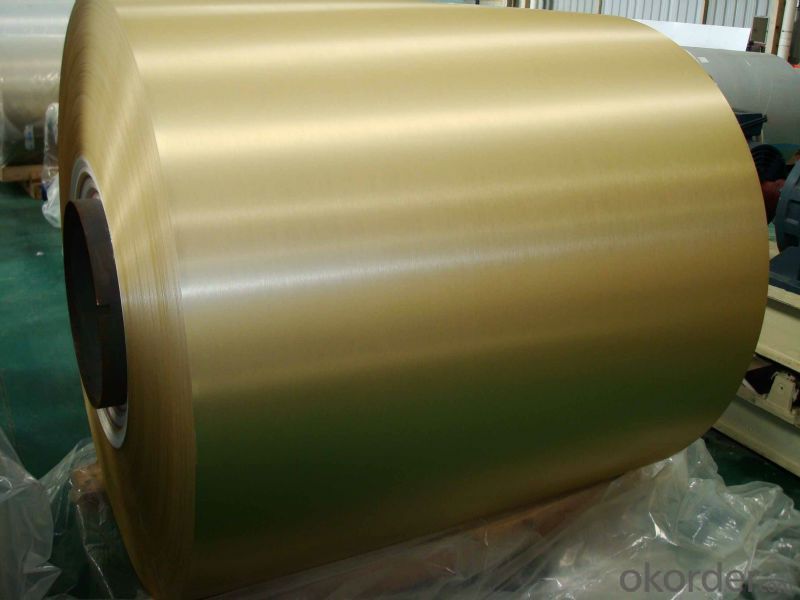

Pre-painted Aluminium Coil 1060 3003 3105 are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Pre-painted Aluminium Coil 1060 3003 3105:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Pre-painted Aluminium Coil 1060 3003 3105:

Pre-painted Aluminium Coil 1060 3003 3105 Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: Guangdong where there are professional to do around the paper corner, is packing steel coil, aluminium coil that protect the edge of the both ends of the cylinder. Just the kind of picture.

- Guangdong Province, professional Foshan recommended edgeboard around Foshan Ansheng packaging. They are very professional in their circle, L shaped, and curved corners.

- Q: What are the typical standards and specifications for packaging aluminum coils?

- <p>The standard specification for aluminum coil packaging varies depending on the industry and region, but generally includes the following: The coil is typically wrapped in a protective film to prevent damage and corrosion. It is often strapped with steel or plastic bands to secure the coil during transportation. The packaging may also include wooden pallets or crates for stability. The dimensions and weight of the packaging are tailored to the coil's size and thickness. Compliance with international standards such as ASTM, ISO, or specific industry standards is crucial. It's important to note that exact specifications can differ based on customer requirements and the end-use application of the aluminum coil.</p>

- Q: This question asks for methods to determine whether an aluminum coil is safe for use.

- <p>To determine if your aluminum coil is safe to use, first, check for any visible signs of damage such as cracks, corrosion, or deformation. Ensure that the coil meets the required specifications for your application, including thickness, width, and alloy type. Verify the coil's compliance with safety standards and certifications relevant to your industry, such as ASTM or ISO standards. Test the coil's mechanical properties to ensure it has the necessary strength and ductility. Finally, consider the coil's history and usage; it should not have been exposed to extreme temperatures or corrosive environments that could compromise its integrity. Consulting with a materials expert or conducting a thorough inspection can provide further assurance of the coil's safety.</p>

- Q: Are aluminum coils suitable for insulation jacketing?

- Indeed, insulation jacketing can be effectively achieved with aluminum coils. Renowned for their exceptional thermal properties, durability, and resistance to corrosion, aluminum coils are a highly favored choice for jacketing material. They find extensive application across diverse industries such as HVAC, oil and gas, and petrochemical, where they serve to insulate pipe systems and equipment. By enveloping insulation materials, aluminum coils play a crucial role in safeguarding against moisture infiltration and sustaining thermal efficiency. Moreover, their lightweight composition ensures effortless installation and transportation. Ultimately, aluminum coils emerge as a dependable and efficient solution for insulation jacketing endeavors.

- Q: Are aluminum coils suitable for marine applications?

- Indeed, aluminum coils prove to be fitting for marine applications. As a material resistant to corrosion, aluminum becomes an ideal option for deployment in marine settings that often encounter saltwater and other forms of corrosive elements. Lightweight, long-lasting, and boasting a high strength-to-weight ratio, aluminum coils hold significance in marine applications where weight reduction is sought after. Moreover, aluminum coils exhibit resilience in the face of extreme temperatures and possess commendable thermal conductivity, rendering them suitable for diverse marine heating and cooling systems. In summary, aluminum coils enjoy popularity in marine applications owing to their corrosion resistance, durability, and lightweight attributes.

- Q: The heat of fusion of aluminum is 3.95kj/g. What is the molar heat of fusion of aluminum? What quantity of energy is needed to melt 10.0g of aluminum? What quantity of energy is required to melt 10.0 mol of aluminum? Three questions i need help with can someone show me step by step please so i can get it thank you a bunch

- This Site Might Help You. RE: heat of fusion of aluminum? The heat of fusion of aluminum is 3.95kj/g. What is the molar heat of fusion of aluminum? What quantity of energy is needed to melt 10.0g of aluminum? What quantity of energy is required to melt 10.0 mol of aluminum? Three questions i need help with can someone show me step by step please so i can...

- Q: Classification of aluminium rolls for aluminium rolls

- On behalf of 6061, mainly contains two elements of magnesium and silicon, so it focuses on the advantages of the 4000 series and the 5000 series, and the 6061 is a cold treatment aluminum forging product, which is suitable for applications with high corrosion resistance and oxidation resistance.

- Q: How do aluminum coils contribute to thermal management?

- The exceptional heat transfer capabilities of aluminum coils are crucial in thermal management. Aluminum possesses a high thermal conductivity, allowing it to efficiently transfer heat from one area to another. This quality plays a vital role in applications that require effective thermal management, including air conditioning systems, refrigeration units, and heat exchangers. In air conditioning systems, aluminum coils are commonly employed in the condenser and evaporator coils. The condenser coil releases heat from the refrigerant to the surrounding air, while the evaporator coil absorbs heat from the indoor air to cool it down. The high thermal conductivity of aluminum ensures efficient heat transfer between the refrigerant and the surrounding air, resulting in faster and more effective cooling. Similarly, refrigeration units utilize aluminum coils in the evaporator coils to extract heat from the interior space. The aluminum coils assist in removing heat from the refrigerated area and transferring it to the outside environment, maintaining a lower temperature inside the unit. Heat exchangers, which are utilized in various industries like automotive, power generation, and HVAC, also benefit from aluminum coils. Heat exchangers are devices that transfer heat between multiple fluids with different temperatures. Aluminum's high thermal conductivity enables efficient heat exchange between the fluids, enhancing overall system performance and energy efficiency. Furthermore, aluminum coils possess lightweight properties and are resistant to corrosion, making them durable and suitable for long-term use in harsh environments. These characteristics further contribute to effective thermal management by ensuring reliable heat transfer and reducing the risk of system failure or decreased efficiency. In conclusion, aluminum coils play a crucial role in thermal management systems by facilitating efficient heat transfer, expediting cooling or heating processes, and improving overall system performance. Their high thermal conductivity, lightweight nature, and corrosion resistance make them the preferred choice in various applications requiring effective thermal management.

- Q: And if the deodorant companies know that aluminum causes cancer, why do they keep putting it in their products?

- Antiperspirant. okorder /

Send your message to us

Prepainted Aluminum Coil for Sale - 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords