Color Aluminum Coil Prepainted-1/3/5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Coil Prepainted Description

Prepainted aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The prepainted aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Coil Prepainted :

1) Perfect weather ability, high strength, no special maintenance

2) Convenient construction, short working time

3) Excellent machining heat insulation, sound insulation property and perfect fireproof performance

4) High plasticity, good impact resistance, quakeproof performance and reducing buildings load

5) Goods smoothness, lightweight and rigid, beautiful and cheap

6) Various colors available

7) Simple machining equipments, processing in spot.

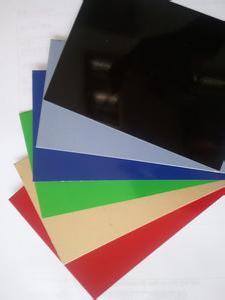

Image of Aluminium Coated Coil:

Aluminium Coated Coil Specification:

Product Name | Aluminum Coil |

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of AA5052 Aluminium Coated Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What is the maximum temperature resistance of aluminum coils?

- The maximum temperature resistance of aluminum coils depends on various factors, such as the alloy composition, purity, and the specific application. However, in general, aluminum has a relatively low melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). Consequently, the maximum temperature resistance of aluminum coils typically ranges between 200 and 400 degrees Celsius (392 to 752 degrees Fahrenheit). Beyond these temperatures, aluminum may start to undergo structural changes, such as softening or deformation, which can impact its performance and integrity. Therefore, it is important to consider the specific requirements and limitations of the application when determining the maximum temperature resistance of aluminum coils.

- Q: Are aluminum coils suitable for architectural roofing systems?

- Yes, aluminum coils are suitable for architectural roofing systems. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for roofs. It can withstand harsh weather conditions, is easy to work with, and offers a range of design possibilities. Additionally, aluminum coils are available in a variety of colors and finishes, allowing for customization and enhancing the aesthetic appeal of architectural roofing systems.

- Q: How are aluminum coils joined in a continuous process?

- Aluminum coils are joined in a continuous process using various techniques such as welding, brazing, and adhesive bonding. Welding is a common method used to join aluminum coils together. It involves melting the edges of the coils and then fusing them together. This can be achieved through various welding processes such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or laser welding. These methods provide a strong and durable bond between the coils. Brazing is another technique used for joining aluminum coils. It involves heating the coils and using a filler material with a lower melting point than the aluminum to create the joint. The filler material, often a brazing alloy, is applied to the joint area, and when heated, it melts and flows into the gap between the coils, forming a solid bond upon cooling. Adhesive bonding is also employed in the continuous joining of aluminum coils. This method involves applying a specialized adhesive or glue to the surfaces of the coils that need to be joined. The adhesive is carefully selected to have excellent bonding properties with aluminum. The coils are then pressed together, and the adhesive cures, creating a strong and reliable bond. Each joining technique has its advantages and is chosen based on factors such as the application requirements, the type of aluminum being used, and the desired level of strength and durability. The choice of joining method in a continuous process depends on the specific needs of the production line and the final product.

- Q: I have a school project due in a couple weeks and I need to make a life size sculpture of a camera. I don't want to make it solid because that would use a lot of clay and wouldn't evenly cook. Can I put something inside like aluminum foil?

- I assume so, since it can go in ovens when you cook. I'd just make sure its in a relatively smooth shape, like folded until it forms a rectangle, before putting it in the clay.

- Q: Are aluminum coils fire-resistant?

- Yes, aluminum coils are fire-resistant.

- Q: What are the different coil handling methods for aluminum coils?

- To ensure the safe and efficient handling and storage of valuable aluminum coils, there are various methods available. Here are several options: 1. Manual Handling: This approach involves the physical lifting and movement of aluminum coils using manual labor. It necessitates proper training and the use of personal protective equipment to prevent injuries. Manual handling is suitable when dealing with smaller coils or when specialized equipment is unavailable. 2. Forklift Handling: Forklifts are commonly utilized for the handling of aluminum coils. They come equipped with specially designed coil lifters or C-hooks, which securely lift and transport the coils. Forklifts offer a more efficient and quicker method for handling larger and heavier coils. 3. Coil Lifters: Coil lifters are specialized lifting devices specifically designed for aluminum coil handling. They utilize a combination of clamps and hooks to securely grip and transport the coils. Coil lifters are often used alongside cranes or forklifts. 4. C-Hooks: C-hooks are another commonly employed method for handling aluminum coils. These hooks are attached to cranes or other lifting equipment and are designed to securely cradle the coil. C-hooks facilitate easy and controlled movement of the coil and are suitable for coils of various sizes. 5. Coil Tippers: Coil tippers are utilized to tilt the coils horizontally or vertically, making loading or unloading easier. This method reduces the risk of coil damage during handling and enhances efficiency by enabling coils to be easily placed on or removed from racks or pallets. 6. Coil Carriers: Coil carriers refer to specialized trailers or trucks specifically designed for transporting aluminum coils. They feature built-in coil cradles or beds that securely hold the coils during transportation. These carriers often have adjustable supports to accommodate different coil sizes and prevent shifting during transit. Ultimately, the choice of coil handling method depends on factors such as coil size, weight, and specific requirements. It is crucial to select the appropriate handling method to ensure worker safety, prevent coil damage, and maintain the quality of the aluminum.

- Q: How would our life on planet earth be modified if there was no aluminum at all? Examples welcomed.

- It would pretty much be the same. Although aluminum is a very useful metal, if it were non-existent, we would simply use other metals or plastics. Plastic is just as infinitely recyclable as aluminum and lighter. Copper, tin, and magnesium (or an alloy of these) could be substitute for aluminum in certain applications. Then there are all these new composite materials being developed, some of which are lighter and stronger then most metals, including aluminum.

- Q: An aluminum bar 3.80 m long has a rectangular cross section 1.00 cm by 5.00 cm, what is the resistance and what is the length of a copper wire 1.50 mm in diameter having the same resistance?

- first ,we will find out the cross sectional area Area= width* height =5.3*2.1=11.13cm^2 Area=11.13 *10^-4 m^2 shear stress = force /area =3.3*10^5/11.13*10^-4=0.296*10^9 Shear stress=2.96*10^8 N/m^2 shear modulus of aluminum=2.6*10^10 pa Shear strain =stress/modulus =2.96*10^8 / 2.6*10^10 =1.14*10^-2 =0.0114 from figure, strain=x/length 0.0114=x/220 (length in mm) x=0.0114*220 x=2.508 mm Ans: Shear deformation is 2.508 mm. ===============================

- Q: A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a safe and commonly used material for food storage due to its non-reactive properties and resistance to corrosion, making it suitable for maintaining food quality and preventing contamination.

Send your message to us

Color Aluminum Coil Prepainted-1/3/5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords