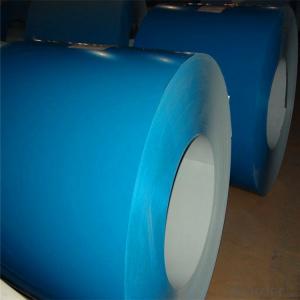

Hot-dip Aluzinc Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product | Hot-dip Aluzinc Steel Sheet |

Thickness | 0.3-3.5mm |

Thickness tolerance | +/- 0.02mm , |

Width | 600-1500mm |

Width tolerance | +/- 2mm |

Length | As to client's require |

Aluzinc coating | 30g-150g |

Standard | ASTM, AISI, DIN, GB,JIS |

Grade | SGCC,DC51D,DX51D,DX52D,,SGCD,Q195,Q235,SGHC,DX54D, S350 GD, S450 GD,S550 GD ect. |

Type | steel sheets/ plates |

Technique | Hot rolled, cold rolled, galvalume / Alu-zinc |

Spangle type | Mini/regular/zero spangle |

Surface treatment | Chromed with passivation / environmental chromed |

Oiled/slightly oiled/ dry/ anti-fingerprint / skinpassed | |

Packing | Standard export packing or following customer's demand |

Delivery Detail | within 40 days after receiving deposit |

Min order | 50 tons |

Coil weight | 3-6 tons |

Grade | Tension Test | ||

Yield Strength (MPa) | Tensile Strength (MPa) | Elongation% No Less Than | |

A80mm | |||

DX51D+AZ | 140-350 | 270-500 | 22 |

DX52D+AZ | 140-300 | 270-420 | 26 |

DX53D+AZ | 140-260 | 270-380 | 30 |

DC54D+AZ | 120-220 | 260-350 | 36 |

Application

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Service

1.MOQ:50 ton.

2.Delivery time:40days

3.Payment:30% deposite, 70% in L/C before delivery.

4.We can guarantee 100% inspeciton before the shipment

5.We can 100% supply MTC.

- Q: I just bought a used Taurus 85 stainless 38 spl revolver, it's about 25 years old but looks like new. This is my first stainless steel gun. I'm wondering if there's any special things I need to be aware of or cleaning methods? I'm also wondering if stainless steel could rust? in theory stainless means it cannot get stained or rusty. I have a chrome bore AK, cleaning is always super easy, wondering of cleaning a SS revolver would be the same.

- Stainless steel does not rust. But your Stainless Barrel is not true stainless steel. True stainless steel is a mix of steel and chrome, and the chrome has a certaion percentage of the overal weight.. But a Stainless barrel does not contain enough chrome to be true stainless, so it can rust.

- Q: How do the sandpaper grits compare with different coarse levels of steel wool? For example, I'm finishing a homemade entertainment center, and using a tinted polyurethane, and it says to use 000 grade steel wool, but mine is #3, could I use some sanpaper instead, and what grit?

- Sand between coats with 220 to 280. 0000 and lemon oil is good for buffing final coat. That is if you don't want a high gloss finish.

- Q: I need a machine which can produce steel pipes, but I don't know where to look...If you want me to state dimensions etc. just say...Thanks :)

- Gary's okorder /

- Q: What are the common surface defects found in steel coils?

- Some common surface defects found in steel coils include rust, scratches, dents, pits, and mill scale.

- Q: Why are properties of steel not identical?

- Grade 440C is one of the highest strength stainless steels. It is also very wear resistant. Good for use as ball bearings and other high wear applications. 400C has the highest carbon content of the 440 steels. 440A and 440B are identical but have lower carbon contents and have lower strengths and higher corrosion.

- Q: What is the weight of a typical steel coil?

- The weight of a typical steel coil can vary depending on its size and thickness, but it typically ranges from a few thousand pounds to several tens of thousands of pounds.

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- Yes. But normal drills are god for steel. Most good regular twist drills sold will go through mild steel no problem. Just so long as you don't buy a wood auger or a carbide-tipped concrete drill

- Q: What are the different methods of coil recoiling for steel coils?

- Steel coils can undergo coil recoiling using various methods, each with its own advantages and applications. Some commonly used methods include: 1. Slitting and rewinding: This method entails cutting the wide steel coil into narrower strips, which are then rewound into smaller coils. Circular blade slitting machines are typically employed for steel cutting, while the rewinding process ensures tight and uniform winding of the narrower strips. Industries like automotive, construction, and packaging widely employ this method. 2. Rewinding with tension control: This method involves unwinding and rewinding the steel coil using tension control systems. These systems maintain consistent tension throughout the recoiling process, resulting in uniform winding quality. This method proves beneficial when handling delicate or sensitive materials that require gentle treatment. 3. Recoiling with edge trimming: In situations where steel coil edges are damaged, uneven, or flawed, edge trimming can be combined with the recoiling process. Edge trimming machines remove defective sections, ensuring coils with smooth and even edges. 4. Recoiling with surface treatment: Steel coils often undergo surface treatment processes like oiling, coating, or galvanizing to enhance corrosion resistance or improve surface properties. Recoiling can be performed alongside these treatments, guaranteeing proper application and uniform coverage across the entire coil surface. 5. Recoiling with tension leveling: Tension leveling is a process that eliminates coil shape defects, such as coil set or crossbow, by applying tension during recoiling. This method ensures a flat and even coil shape, which is advantageous for subsequent processing and manufacturing operations. 6. Recoiling with precision slitting: Precision slitting is a specialized method used to achieve extremely narrow strip widths or tight tolerances in the steel coil. It involves precise control of slitting knives and winding tension to ensure accurate and consistent strip dimensions. Industries requiring high precision, such as electronics or precision engineering, commonly employ this method. In summary, the choice of coil recoiling method depends on factors such as desired coil dimensions, material characteristics, surface requirements, and the specific industry or application. Manufacturers often combine multiple methods to meet the diverse needs of their customers.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q: Just two sentences on a detailed description on what the steel industry is

- The steel industry is an industry that produces steel. It is one of the largest industries in the world, with China as the leading steel producer

Send your message to us

Hot-dip Aluzinc Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords