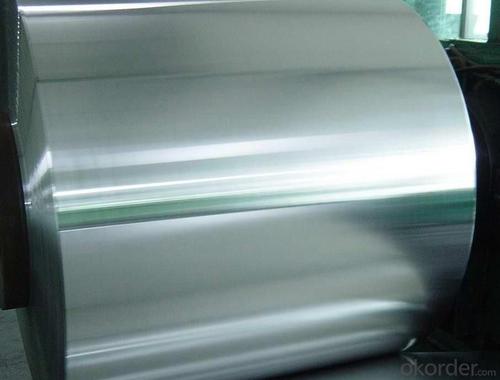

HOT-DIP ALUZINC STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | Brand Name: | N/M | Model Number: | ssp-226 | |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- steel fo shizzle, glass can break, but steal goes threw. And wat are u hunting for dear? lol

- Q: I know that they have steel shot in smaller sized pellets....say, number 4 shot. I guess it's for waterfowl, etc.Do they make steel buckshot? If not, why not? Would the pellets be too heavy? Wouldn't they have excellent penetration ability?

- No Steel Buckshot ...Yet... The whole idea behind steel shot was because there were a very large number of migratory birds, Geese, Ducks, etc dying after being hit with lead shot and developing infections, and lead poisoning, that ultimately killed or crippled too many birds. The Federal government stepped in and made Steel Shot a requirement for hunting all migratory birds. I think the biggest reason that Steel Buckshot isn't made yet is because it can only be fired out of modern, newly manufactured shotgun barrels and unless you have a shotgun designed to be used with steel shot, it would be damaged along with chokes made for lead shot only..I have no doubts that it's probably coming in the near future....Note* Penetration was never an issue, nor was the weight.........

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- Steel is magnetic because of the alignment of the spin in the electrons of the atoms in the crystaline matrix of the steel. Nickel atoms are not the same size as Iron atoms and Chromium atoms. by having several different sizes of atoms in the alloy, it prevents a uniform crystaline matrix from being formed. If you imagine a box of marbles that are all the same size, they will all settle into a regular pattern in the box. But a bunch of mismatched marbles will be jumbled together in irregular patterns. This prevents the magnetic properties of either element from asserting itself.

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on various factors such as the size, thickness, grade, and market conditions. It is best to contact a supplier or check current market prices for an accurate cost.

- Q: How are steel coils used in the manufacturing of hydraulic cylinders?

- Steel coils are used in the manufacturing of hydraulic cylinders as the raw material for creating the cylinder body. The steel is typically rolled into a coil form and then cut into specific lengths and shapes to construct the cylinder barrel. This allows for precise and durable construction of hydraulic cylinders, ensuring they can withstand high pressure and heavy loads.

- Q: What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and dents, as well as internal defects like inclusions, cracks, and voids. Other common defects can include uneven thickness, waviness, and coil set.

- Q: I know there is soft steel and sturdier steel they use in products. The sturdier often used for equipment that requires more durability when in operation.

- harder steel has a higher carbon and chromium content

- Q: What are the different surface finishes available for steel coils?

- Some of the different surface finishes available for steel coils include hot-dip galvanized, galvannealed, electro-galvanized, and plain.

- Q: What are the different methods of roll forming steel coils?

- There are several different methods of roll forming steel coils, including hot rolling, cold rolling, and continuous casting. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through a series of rollers to shape it into the desired form. Cold rolling, on the other hand, is performed at room temperature and involves passing the steel through rollers to increase its strength and improve surface finish. Continuous casting is a method where molten steel is continuously poured into a mold and then cooled to form a solidified strip or slab. These methods offer different advantages and are used in various applications based on the desired properties of the steel product.

- Q: Well actually I was just wondering why people were bashing on stainless so much for katanas. I heard that they don't hold their edge as well as carbon steel blades or Damascus steel. So what makes it so inferior to carbon or other types of steels?

- There are many kinds of stainless steel. 440c, 420j, ATS34, and so on. Cold steel uses 420 type steels in several of their products. High carbon stainless steels cut well but edge retention is not very good but that also depends on the heat treating of the metal. I could go on all day but very, very basically stainless steels lack the shatter resistance necessary when stretched to great lengths. This is in part why other steels make far better swords. The stuff sold on QVC is just plain junk. Do not buy a stainless steel sword. A blade made of 440S means it belongs hung on a wall...

Send your message to us

HOT-DIP ALUZINC STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords