Hot Dipped Aluzinc Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Dipped Aluzinc Galvanized Steel Coil

Description of Hot Dipped Aluzinc Galvanized Steel Coil

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Hot Dipped Aluzinc Galvanized Steel Coil

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

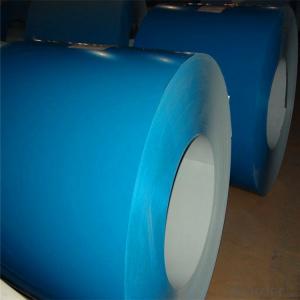

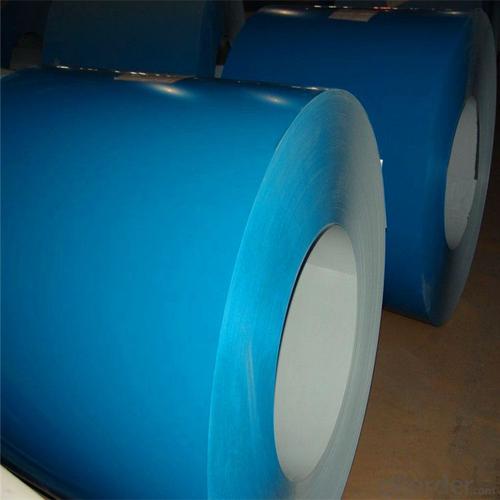

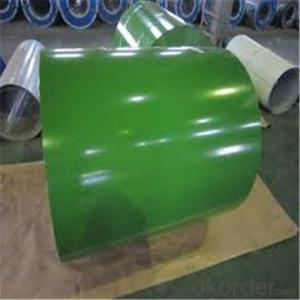

Products Show of Hot Dipped Aluzinc Galvanized Steel Coil

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel perform in high-pressure environments?

- Special steel performs exceptionally well in high-pressure environments due to its unique composition and properties. It is designed to withstand extreme pressure and temperature conditions without deforming or losing its structural integrity. The high tensile strength and hardness of special steel enable it to resist the forces exerted by high pressures, making it an ideal material for applications such as oil and gas pipelines, pressure vessels, and hydraulic systems. Additionally, special steel's excellent corrosion resistance ensures its durability and longevity in aggressive environments, further enhancing its performance in high-pressure settings.

- Q: How is special steel used in the packaging supply chain?

- Special steel is used in the packaging supply chain for various purposes such as manufacturing machinery, tools, and equipment needed for packaging processes. It is used to create durable and reliable components like blades, cutters, and molds, ensuring precise and efficient packaging operations. Additionally, special steel can be utilized for constructing robust packaging materials like containers, pallets, and racks, providing strength and stability during transportation and storage.

- Q: How does special steel contribute to the pharmaceutical industry?

- Special steel contributes to the pharmaceutical industry by providing the necessary materials for the production of high-quality equipment and tools. It is used in the manufacturing of pharmaceutical machinery, such as reactors, mixers, and pumps, that require corrosion resistance and hygienic properties. Special steel also plays a crucial role in the construction of storage and transportation containers for pharmaceutical products, ensuring their safety and efficacy.

- Q: How does special steel contribute to the automotive noise reduction?

- Special steel contributes to automotive noise reduction in several ways. Firstly, it is used in the manufacturing of the vehicle's structure and body, providing high strength and stiffness, which helps reduce vibrations and noise transmission. Additionally, special steel can be used in the production of engine components, such as exhaust systems, mufflers, and catalytic converters, which help dampen and absorb noise generated by the engine. Furthermore, the use of special steel in the construction of suspension systems and other mechanical components can also contribute to minimizing noise and vibrations, resulting in a quieter and more comfortable driving experience.

- Q: How does special steel contribute to reducing greenhouse gas emissions?

- Special steel can contribute to reducing greenhouse gas emissions in several ways. Firstly, it can be used in the manufacturing of more energy-efficient vehicles, which emit lower levels of carbon dioxide during operation. Additionally, special steel can be utilized in the production of renewable energy infrastructure, such as wind turbines and solar panels, which helps reduce reliance on fossil fuels. Furthermore, special steel is often employed in the construction of energy-efficient buildings, which require less energy for heating and cooling, thus lowering overall emissions. Overall, the use of special steel in various applications plays a significant role in the reduction of greenhouse gas emissions and the transition to a more sustainable future.

- Q: What are the different methods of surface pickling for special steel?

- Pickling special steel can be achieved through various methods. These methods comprise acid pickling, electrolytic pickling, mechanical pickling, and passivation. The most commonly employed method for pickling special steel is acid pickling. It entails immersing the steel in an acid solution, typically hydrochloric acid or sulfuric acid, to eliminate any surface impurities. By reacting with the steel's oxide layer, the acid dissolves it, leaving a pristine surface. Electrolytic pickling, on the other hand, involves passing an electric current through the steel submerged in an electrolyte solution. This creates a chemical reaction that removes surface impurities. Electrolytic pickling offers better control and enables a more consistent surface finish compared to acid pickling. Mechanical pickling utilizes abrasive materials like sandpaper or wire brushes to physically scrub the steel's surface and eliminate any scale or rust. It is often combined with acid or electrolytic pickling to achieve the desired surface finish. After pickling, special steel can undergo passivation to enhance its corrosion resistance. Passivation entails treating the steel with a chemical solution, typically nitric acid or citric acid, to form a protective oxide layer on the surface. This layer prevents further corrosion and enhances the steel's overall durability. It's worth mentioning that the specific method of surface pickling for special steel may vary depending on factors such as the type of steel, desired surface finish, and intended application. Therefore, it is essential to consult experts or adhere to the manufacturer's guidelines to ensure the appropriate pickling method is employed for special steel.

- Q: How long does special steel last compared to regular steel?

- Special steel generally lasts longer than regular steel due to its superior properties and enhanced durability.

- Q: How does special steel contribute to the mining aftermarket industry?

- Special steel plays a crucial role in the mining aftermarket industry by offering enhanced durability, strength, and resistance to extreme conditions. This type of steel is specifically designed to withstand the demanding environments and heavy loads associated with mining operations. In the mining aftermarket industry, special steel is used to manufacture various equipment and components, such as drill bits, cutting tools, crusher parts, and wear plates. These components are subject to intense wear and tear due to the abrasive nature of the materials being mined. Special steel, with its superior hardness and toughness, ensures that these components can withstand the harsh conditions and maintain their performance over an extended period. Furthermore, special steel allows for the development of more efficient and productive mining equipment. By using high-strength steel alloys, manufacturers can design lighter equipment without compromising on strength and durability. This results in increased productivity and reduced operating costs for mining companies. Special steel also contributes to the safety of mining operations. The robustness and reliability of steel components minimize the risk of unexpected failures, which can lead to accidents and downtime. Additionally, special steel can withstand extreme temperatures, corrosion, and other environmental factors commonly encountered in mining, reducing the need for frequent replacements and repairs. In summary, special steel is essential to the mining aftermarket industry as it provides the necessary strength, durability, and resistance to extreme conditions required for mining equipment and components. It enhances productivity, reduces operating costs, and ensures the safety of mining operations, making it a critical material in the mining industry.

- Q: Can special steel be coated?

- Yes, special steel can be coated. Coating special steel provides several benefits such as corrosion resistance, improved aesthetics, increased durability, and enhanced functionality. There are various coating materials and techniques available for special steel, including but not limited to electroplating, hot-dip galvanizing, powder coating, and ceramic coating. These coatings help protect the steel from environmental factors, chemical exposure, and wear and tear, thereby extending its lifespan and maintaining its performance. Additionally, coatings can also be customized to provide specific properties like non-stick surfaces, heat resistance, or anti-microbial properties, depending on the intended application of the special steel.

- Q: What are the different methods of hardening special steel?

- There are several methods of hardening special steel, each with its own advantages and applications. 1. Quenching: This is a common method used to harden steel. It involves heating the steel to a critical temperature and then rapidly cooling it by immersing it in a quenching medium such as oil, water, or air. This rapid cooling causes the formation of a martensitic structure, which is harder and more brittle than the original steel. 2. Tempering: After quenching, the steel is often tempered to reduce brittleness and improve toughness. Tempering involves reheating the hardened steel to a specific temperature and holding it at that temperature for a predetermined amount of time. This process helps to reduce internal stresses and improve the overall mechanical properties of the steel. 3. Case hardening: This method is used to increase the hardness of the outer layer of steel while maintaining a tough and ductile core. Case hardening involves introducing carbon or nitrogen into the surface of the steel through processes like carburizing or nitriding. This creates a hard surface layer while maintaining the desired properties in the core. 4. Induction hardening: This technique is commonly used for specific areas of a component that require localized hardening. It involves using an electromagnetic field to heat only a specific region of the steel, followed by rapid quenching. Induction hardening provides precise control over the hardened area while maintaining the desired properties in the rest of the component. 5. Cryogenic treatment: This method involves subjecting the hardened steel to extremely low temperatures, often below -150°C (-238°F). This process helps to further refine the microstructure of the steel, improving its hardness, wear resistance, and dimensional stability. 6. Flame hardening: This method involves heating the surface of the steel using a high-temperature flame and then quenching it. Flame hardening is commonly used for large components or areas that require localized hardening. It is important to choose the appropriate method based on the specific requirements of the steel and the intended application. The selection of the method depends on factors such as the desired hardness, toughness, wear resistance, and dimensional stability of the steel.

Send your message to us

Hot Dipped Aluzinc Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords