GL prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.17mm-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | Corrugated sheet | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Roofing,Ceiling,Roof | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | as per customers request | Zinc coating: | 60-275g/m2 | Surface processing: | Regular spangle,minimal spangle |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy or as your requirement. |

| Delivery Detail: | Within 9 days after confirming the order. |

Specifications

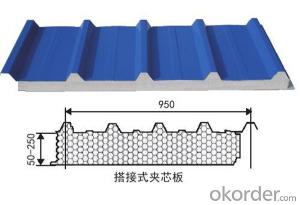

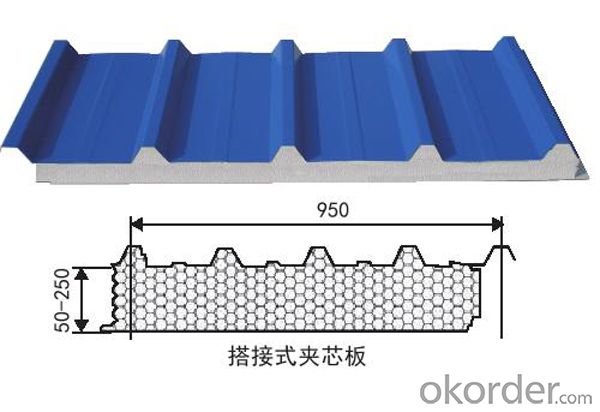

Prepaint corrugated roofing sheet

1.our material are from big mill

2.surface and edge is glossy

3.our package is export pa

Prepainted corrugated steel roofing sheets

Production

Standard | JIS G3302 1998, ASTM A653M/A924M 2004,or according to your request |

Thickness | 0.13mm-1.5mm |

Width | 400mm-1250mm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Length | We can adjust the length according to your request |

Wave depth | As to requirement |

Zinc Coating | 40g/m2-275g/m2 |

Surface treatment | Color-Coated & Galvanized |

Color | All RAL color |

Coat | 25±5μm on front coating and 7± 2μm on back coating |

Temper | 1.Full hard |

2.Commercial quality | |

3. Dry, chromate, skin passed, tension level, shining. | |

Spangle | Regular spangle, minimized spangle and zero spangle |

Tensile Strength | >300mpa |

Yield Strength | 370-380mpa |

Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

MOQ | 50Ton |

Specification

Process ability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: Can steel sheets be used for construction purposes?

- Yes, steel sheets can be used for construction purposes. They are commonly used in various construction applications such as roofing, wall cladding, flooring, and structural components due to their durability, strength, and resistance to fire and corrosion.

- Q: Can steel sheets be used for agricultural buildings or barns?

- Yes, steel sheets can be used for agricultural buildings or barns. Steel sheets offer numerous advantages for these types of structures. Firstly, steel is a durable and long-lasting material, ensuring that the agricultural building or barn will be able to withstand the test of time and various weather conditions. Steel is also resistant to pests such as termites, which can be a common problem in wooden structures. Additionally, steel sheets are fire-resistant, providing an added layer of safety. Moreover, steel sheets are highly customizable, allowing for flexibility in design and construction. They can be easily cut and shaped to fit the specific needs and requirements of the agricultural building or barn. Steel sheets are available in various thicknesses, providing options for different levels of strength and structural integrity. Furthermore, steel is an environmentally friendly choice for agricultural buildings or barns. It is a recyclable material, meaning that at the end of its lifespan, it can be repurposed and reused, reducing waste and minimizing the environmental impact. Considering all these factors, steel sheets are a great choice for agricultural buildings or barns due to their durability, pest resistance, fire resistance, customizability, and environmental friendliness.

- Q: What are the common sizes of steel sheets?

- Common sizes of steel sheets vary depending on the industry and application, but some standard sizes include 4x8 feet (1.2x2.4 meters), 4x10 feet (1.2x3 meters), and 5x10 feet (1.5x3 meters). Other sizes may also be available depending on the manufacturer and customer requirements.

- Q: What is the maximum width of steel sheets available?

- The maximum width of steel sheets available can vary depending on the manufacturer, but it is typically around 72 inches or 6 feet. However, some manufacturers may offer wider options up to 120 inches or 10 feet. It is important to check with specific suppliers or manufacturers to determine the exact maximum width available for steel sheets.

- Q: What are the properties of steel sheets?

- Steel sheets have a number of properties that make them highly desirable in various industries. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads and have a high resistance to impact and deformation. This makes them ideal for applications where strength is crucial, such as construction, automotive, and aerospace industries. Another important property of steel sheets is their excellent corrosion resistance. Steel is typically coated with a thin layer of zinc or other protective materials to prevent rusting and corrosion. This protective coating enhances the longevity of steel sheets, allowing them to be used in outdoor or humid environments without the risk of degradation. Steel sheets are also known for their versatility. They can be easily bent, shaped, and welded, which makes them suitable for various fabrication processes. This adaptability enables manufacturers to create complex structures and components with ease, making steel sheets a popular choice in architectural and industrial designs. Furthermore, steel sheets have excellent thermal conductivity. This property allows them to efficiently transfer and distribute heat, making them ideal for applications where temperature regulation is required, such as in heating systems or electrical appliances. Lastly, steel sheets are highly recyclable, making them an environmentally-friendly choice. Steel is one of the most recycled materials in the world, and the recycling process does not compromise its properties or quality. This sustainability factor makes steel sheets a preferred option for those looking for eco-friendly materials. In summary, the properties of steel sheets include strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability. These qualities make steel sheets a reliable and versatile material for various industries and applications.

- Q: Are steel sheets suitable for decorative screens or partitions?

- Yes, steel sheets are suitable for decorative screens or partitions. They offer durability, strength, and a sleek aesthetic that can enhance the overall design of any space. Additionally, steel sheets can be customized with various patterns, textures, and finishes, allowing for endless creative possibilities in creating decorative screens or partitions.

- Q: Are steel sheets suitable for outdoor sculptures or artwork?

- Yes, steel sheets are suitable for outdoor sculptures or artwork. Steel is a durable and weather-resistant material that can withstand various outdoor elements such as rain, wind, and sunlight. It allows artists to create intricate and large-scale structures that can be placed outdoors without the risk of damage or deterioration. Additionally, steel sheets can be easily manipulated and welded, providing artists with the freedom to shape and form their artistic vision.

- Q: Can steel sheets be rolled into cylinders or tubes?

- Yes, steel sheets can be rolled into cylinders or tubes through a process called tube or cylinder rolling.

- Q: Can steel sheets be used for containers or storage units?

- Containers or storage units can certainly utilize steel sheets. Steel, a highly durable and strong material, is commonly employed in constructing containers and storage units due to its capacity to withstand heavy loads and extreme weather conditions. These steel containers and storage units offer a secure and dependable solution for storing a variety of items, ranging from household goods, tools, and equipment to even larger items such as vehicles. To enhance their functionality, steel sheets used for containers and storage units are often fortified with additional features like locking mechanisms, insulation, and ventilation. Moreover, steel containers and storage units are portable and can be easily transported to different locations when necessary. In summary, steel sheets are an exceptional choice for containers and storage units due to their strength, durability, and versatility.

- Q: Are steel sheets suitable for oil rig platforms?

- Yes, steel sheets are suitable for oil rig platforms. Steel is commonly used in the construction of oil rig platforms due to its strength, durability, and ability to withstand harsh offshore conditions. It provides the necessary structural integrity and resistance to corrosion, making it a reliable choice for such applications.

Send your message to us

GL prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords