Ceramic Fiber Blanket 50mm 128kg/m3 1260STD

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite of Ceramic Fiber Blanket

Ceramic Fiber Blanket is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Types of Ceramic Fiber Blanket: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Blanket also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Blanket

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Blanket

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

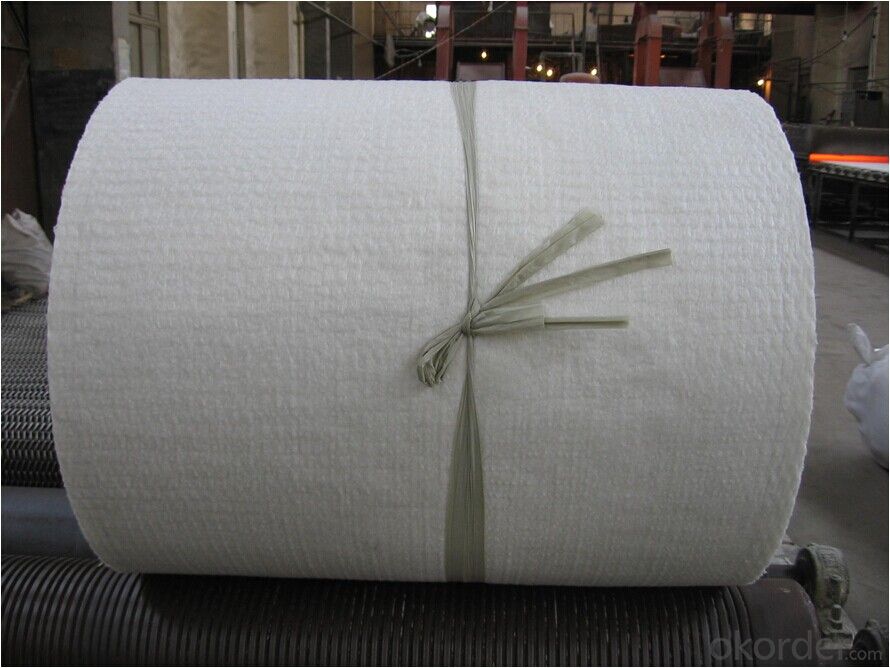

Ceramic Fiber Blanket Images

Ceramic Fiber Blanket Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | -3 | -3 | -3.5 | 3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Blankt

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: I've been sick for about 5 days nowI've stayed home from school for 4I've had a fever for everydayYesterday, I went to a doctor and he prescribed me some medicineSo here is how it has been likeWake up feeling like poop; eventually feeling better throughout the day; once night falls, my body starts burning up againI have been keeping myself hydrated and etcToday, I felt like i was going to get better by tomorrowHowever, here I am at 9:42, burning up againI am resided in California by the way, the average night time temperature is around 66, more or lessWhat am i supposed to do when night comes so i don't get a fever? Do i stay under blankets? Wear layers? It seems as they would cause the fever to be worseAnyways, I'm not a doctor, but sure would like some advice! So, what do i do?!

- I constantly theory it substitute into in simple terms gliding, yet apparently they'd and do fly Band-wing flyingfish Cheilopogon exsiliens, with super pectoral and pelvic finsTo prepare for a flow, the fish have the means to swim as we communicate on the brink of the outdoors of the water, with their fins on the brink of the physiqueAs they leave the water, they unfold their finsThe caudal fin is regularly deeply forked, with the decrease lobe longer than the betterThe fish as we communicate circulate the decrease lobe to propel themselves forward as quickly as the the remainder of the physique has already left the waterfinally, even the tail leaves the water and the fish are airborneFlying fish can attain heights as much as a million.2 metersthey'd even flap their wingsIn gliding, flying fish can exceptionally much double their velocity, reaching accelerates to 60 km/hThe glides are regularly as much as 30-50 metres in length, yet some have been observed hovering for hundreds of metres making use of the updraft on the main effective edges of wavesThe fish could additionally make a chain of glides, each and every time dipping the tail into the water to produce forward thrust.

- Q: After looking a little closer as to why my vent won't spin while my neighbors is spinning like crazy I found that the insulation covers all the vents under the roof eave (soffit vents?)From what I can find online this needs to be correctedDo I just pull the insulation back away from the vents? And does anyone suggest installing a gable mount attic fan? I'm trying to reduce my electric billThanks a lot.

- Roof turbines will exhaust about the same amount of air when they are spinning as when they don't spinHaving the soffit vents clear and no obstructions between there and the free air space in the attic are the main factors in how well the attic is vented.

- Q: What type of fabric is best for a heavyweight blanket that has a little bit of stretch?

- I hear your having trouble getting to sleep, i doubt you haven't tried counting sheep, But have you tried these simple steps, that let you get your well deserved rest? first you snuggle into bed, grabbing a pillow - rest your head, now think of something you'd like to say, something that wouldn't make anyone's day, think of all your craziest ponders, then enter a world of various wonders ~Ainahs Rekab

- Q: I'm not to sure what to doCan anyone help??

- No, it won't release and your cake will get stuck in all the little indentationsUse the Pyrex dish instead.

- Q: having yogurt, raisins/ prunes, fruit fresh/veggies, fiber pasta, high fiber cereals, nuts light tho not too much tho eating alot of up above not much meat its hurtful to my body and can't digest well

- That sure is alot of fiberDo you have a medical condition that requires you eat that much? If so, I'd suggest talking to your doctor about setting up a good diet tailored to your specific needsLooking at what you listed above, in my non-professional opinion, I'd say you need more proteinIf that's pretty much all you eat you are going to be severly protein deficientIf you just can't handle meat look into alternatives like eggs, peanut butter, tofu, ect.

- Q: What is a good, vsquot;recommendedquot;, thickness of a dense/closed cell spray foam insulation for heating/cooling air supply ducts running above the unheated garage to a room above itFrom what I can see, the builder did about 2-3 inches, and the air going thru that stretch is being cooled off big timeI know for a fact there's a great temperature loss in there during cold winter months.Would there be a benefit to spray a couple of more inches? I have 8quot; joists and 5quot; duct work, that leaves about 3quot; left for foam, I figuredIn the area where the ducts runs underneath and across the joists, the thickness measured was about 2quot;

- take a break from blue moon belgian white a 164 calorie treat and grab a miller genuine draft which is only 64 cals

- Q: When the weather is cold, what is the best way to stay warm?

- Wait.Romney has female body parts? Always knew he was a big PNow I know why.

- Q: What are the materials used in thermal insulation? andWhat is the best material used in thermal insulation and noise?

- Yes you can make a rocket using an aluminum tube with powdered zinc and sulphur as a fuelit is very dangerous just as a rocket fueled with gun powder is.

- Q: I have $70which ones are better? i have short think hair, and I need an iron that wont burn, and break my hairany sugustions? I also have to get some type of something that you put in your hair before you blow dry and straighten my hair? ??? Help!

- At Target, NoneBefore you do target, go to your local mall and see if you can find a kiosk that carries the 'herstyler' I think you can get those for 35-55Make them give you the best priceAnd a good thermal protector would be from chi, or GHD(the matrix copy by suave isnt too bad if you are in a pinch) But if you must use Target, get the iron that has the most tourmaline plateTourmaline is EXTREMELY important for reducing damage especially when you need such high heat to get through thick wavesI think the best target has is tourmaline fused; but even that is better than nonecheers Oh yes, also check online for Nikki clarke irons, I saw some recently fairly priced, 49maybeGreat Irons, they boast hottest temps, and tourm platesgood luck

- Q: I have a 6 month old guinea pig who jumps and runs around her cage all the time, i've tried tons of different bedding and the only one i have found that she is not allergic to is, Soft SorbentAll the others she sneazes when she comes in contact with them! She had an upper respritory infection when i bought her from petsmart which is why i think she has those allergies! But i want to find something that she cant throw around, because the soft sorbent is like little pellet things that when she runs around she flings all over my room and i've had enough of picking up my room and vacuuming for an hour to clean it all up every week! So i was looking up little mat like things that i can just put on the ground and pick up and clean every couple of days or so, but there is only one and people tell me that she may be alergic to it because it makes alot of dust! Then i looked up Fleece, and it looks like it would work but i know nothing about it, how do i use it? What do i need to get with it?

- I can't tell you if your guinea pig will be allergic to fleece or notI suggest buying a small fleece blanket (cut any decorative stitching off the edge before giving it to your guinea pig) or getting some from a fabric store and put it in her cage with the bedding you are using and see if it causes her to sneezePolar fleece (which is normally just called fleece) is made from synthetic fibers, not made from woolIt is a safe fabric for animals because it is a short fiber fabricSome tips for using fleeceFleece doesn't absorb and hold liquid in the fabric very wellIt mostly pulls the liquid below the fleeceSome people use other fabrics under fleece to absorb liquidJust make sure your guinea pig cannot get to or at least doesn't chew on the other fabricBefore using a new piece of fleece, you should wash it two or three times or the urine will just bead up on top of the fabric for a long time before soaking downYou don't have to hem fleeceIt won't fall apart in the wash if it hasn't been hemmedVacuum or shake the fleece off very well before washingYou can add 1/4 cup of vinegar to the water when washing to rid it of urine smellsIf you use a laundry detergent, make sure it is a very gentle, fragrance free brandFleece is a very light fabric so you might want to attach it to the sides of the cage or weigh it down in each cornerYou should attach or weigh it down if you use another fabric under itYou will need wash or change the fleece bedding every 2-3 daysIt helps to have more than one setSometimes it is cheaper to buy fleece blankets in the store rather than buying it by the yard at a fabric storeLike I said before, cut off the decorative stitching on the edge, if it has anyThe stitching isn't safe for animals.

Send your message to us

Ceramic Fiber Blanket 50mm 128kg/m3 1260STD

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords