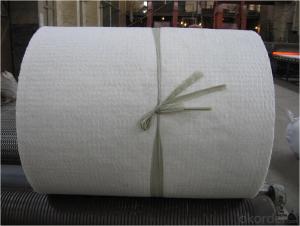

Ceramic Fiber Blanket for Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Heat Insulation Ceramic Fiber Blanket (High Pure)

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 10-50mm |

| Width: | 610,1220mm | Length: | 3600,7200,14400mm | Chemical Composition: | Al2O3 |

| Ultimate Strength (≥ MPa): | 0.08-0.12 | Working Temperature: | 1260C | Fiber Diameter: | 3-4.5micron |

| Shrinkage (1800 ℉, 3h): | -3 | Thermal Conductivity: | 0.22 | Density (kg/m³ ): | 128 |

| Model Number: | 7200X610X25mm or 3600X610X50mm | Brand Name: | Place of Origin: | (Mainland) |

Packaging & Delivery

| Packaging Detail: | Woven bag,carton or according to customer's requirement |

| Delivery Detail: | 15 days |

Specifications

High Pure Ceramic Fiber Blanket

Working Temperature:1100~1430 Celsius degree

Density:96~128kg/m3

Thick:10~50mm

Product description:

The Ceramic Fiber Needle-punching Blanket is made through intensive needle-punching processing.The product does not contain any bond or other compositions,and also no slag inclusion content. The intensive needle-punching technics improved the fiber intertexture and the resistance performance against delamination as well as the tensile strength.It have a good high temperature shrinkage after the heat treatment of 750-950 during the producing. Beside the charicteriatics in common,it have better sound insulation performance and mechanism strength,is easy to machining and install.

Product Features:

Low thermal conductivity ,heat storage and heat capacity

Excellent heat insulation

Excellent chemical stability

Shock and chemical attack resistant

Low thermal conductivity and shrinkage

Resilience under working condition, Low shrinkage under high temperature

Excellent sound insulation and resistance of folding

Product application:

Industrial furnace,Heat treatment,High temperature pipe

Insulating materials of boiler, turbine and nuclear power

Insulating material for face and top of industrial furnaces and heating device

Excellent sound insulation for Construction Fire protection

High temperature filter material for nonferrous metal

The Technical Specification:

| ITEM | PRODUCT | COM | STD | HP | HA | HZ |

| Classification TemperatureºC | 1100 | 1260 | 1260 | 1360 | 1430 | |

| Working TemperatureºC | <1000 | 1000 | 1100 | 1200 | 1350 | |

| Color | white | white | white | white | white | |

| Densitykg/m3 | 96 128 | 96 128 | 96 128 | 128 160 | 128 160 | |

| Liner Shrinkage% After 24hours | -4 | -3 | -3 | -3 | -3 | |

| 1000ºC | 1000ºC | (1100ºC) | (1250ºC) | (1350ºC) | ||

| Thermal conductivityw/m.k density128Kg/m3) | 0.09 | 0.09 | 0.09 | 0.132 | 0.76 | |

| 400ºC | 400ºC | 400ºC | 600ºC | 600ºC | ||

| 0.176 | 0.176 | 0.176 | 0.22 | 0.22 | ||

| 800ºC | 800ºC | 800ºC | 1000ºC | 1000ºC | ||

| 0.22 | 0.28 | |||||

| 1000ºC | 1200ºC | |||||

| Tensile strengthMPa | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

| Chemical Composition % | Al2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2 | 96 | 97 | 99 | 99 | - | |

| Al2O3+SiO2+ ZrO2 | - | - | - | - | 99 | |

| ZrO2 | - | - | - | - | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

| Size(mm) | Specification:7200X610X10-50,other according to customer's requirement | |||||

- Q: Lately I've been having really bad stomach aches, horrible gas, and diarrheaI had some weird quot;colitisquot; earlier this year, which was cramps so bad I couldn't move followed by non-stop vomit (gross, I know), but the doctor said it should go away and not come backHowever, recently I've been having some of the similar symptoms and more, my stomach feels like it is going to explode, like I'm really bloatedDoes anyone have any ideas about what this could be? Maybe a food allergy?? Help!

- It is possible that you have irritable bowel syndrome (IBS)It's not fun, I know, because I have it tooBut as the first person who answered said, because of the vomiting, it is possible that you have a bowel obstructionShe is rightYou should go to your closest emergency room if you can't pass a bowel movement and start vomiting againPeople with IBS have to be really disciplined with their diet and exerciseI usually find cooked vegetables easier to handleIf I eat too much salad I am likely to have an IBS attackAlso, with IBS it is important to cut down on fat and sugar consumptionSpicy foods can also be difficult to digestAs much as I love East Indian food, I would recommend staying away from it and similar foodsPeople with IBS need to eat enough fiber, but some fibers are soluble, while others are insolubleCooking your veggies turns the fiber into soluble fiber, which is easier to digestAlso, make sure to drink plenty of WATERI can't emphasize enough how important drinking water isAs difficult as it is, you may have to cut coffee and other forms of caffeine out of your dietI know that this all may seem rather extreme, and you may find that once you get on track with your diet, you can allow yourself to have some treats in moderationYou might want to keep some anti-gas Rolaids on handGood luck.

- Q: We have a temperature problem at our houseMy princess is an oven when she goes to sleepShe sweats and leaves wet places, even in only a onesieThen she gets cold and wakes upIf I put her in a footed outfit or one of those sleep sacks, she burns upI'm not supposed to use blankets, so Any ideas?

- another saying we can use for horse shoe will be boots haven't know any brand yet :) in bahasa language: sepatu kuda in serbocroatian: kopita

- Q: Several years ago, for a team building activity I made a twisted rope out of yarnEach person had a different piece of yarn and there was PVC piping that we used to twist and make the ropeThe point of the activity was that everyone worked together and that as individuals we can come together and make something strong like how the individual strings make a strong ropeI want to do this activity at a leadership retreat and am looking for instructions on how to do this.

- for a 5 foot piece of rope, you need to measure 12 feet of various kinds of yarns(this requires 2 to 3 people measuring each one.) Then tie the strands together with overhand knot and slip a broom stick through the yarns on each end, making sure the yarns are all the same length., a couple of people down the length of the yarns and one or two in centerEach end twists the yarns clockwise from their endpeople in middle keep the rope from kinkingone end is folded over another broom stick and brought to other endThese are turned loose by remmoving the sticksNow the rope is smoothed out from the middle to both endsNote: I am a spinner and make my own yarns from various natural fibers and some exotic ones tooI use a spinning wheel to do thisThen the yarns are ready to be used on my loom/ the sheeps wool for instance is very fine and fragile pulling apart really easily, but when it is spun into singles it is much stronger and harder to break, when I make it into 2 ply or more yarn, it is really hard to breakMuch stronger yarn than synthetic yarns are.

- Q: What's the difference between blanket, comforter, duvet?

- Hi there :) A duvet (pronounced /du?ve?/, from the French duvet /dyv?/ down) is a type of bedding— a soft flat bag traditionally filled with down or feathers, or a combination of both and used on a bed as a blanketDuvets originally came out of rural Europe and were made of Eider, a type of duck's down, which is well known for its usefulness as an insulatorA comforter is a type of bedding — a soft flat bag used on a bed as a type of bed coverIt is filled with either an artificial material (such as polyester batting) or a natural materialA comforter usually doesn't cover the pillows or box spring of the bedIt is basically a luxurious thick, fluffy blanket that people put on their bed to achieve a much higher level of comfort and warmthA similar type covering made from feathers (often including down) is generally referred to as a duvetA blanket is a type of bedding, generally a large, rectangular piece of cloth, intended to keep the user warm, especially while they sleepBlankets are distinguished from sheets by their thickness and purpose; the thickest sheet is still thinner than the lightest blanket, because blankets are for warmth, while sheets are for hygiene, comfort and aestheticsBlankets are subdivided into many types, including quilts, duvets, and comforters, depending on their thickness, construction and/or fill materialElectric blankets are heated by electricityBlankets were traditionally made of wool, while sheets were made of cotton which is less irritating to the skinThese days, artificial fibers are frequently used for bothHope this helps.

- Q: Looking to put some insulation in our attic and had a few contractors come over and tell me where they would spray the insulationOne guy said he would spray the ceiling/roof and the wall facing inThe other guy said he would insulate the floor and wall and leave the ceiling aloneAnyone have a thought what is right or better? both make sence to me but would like some input from others! thanks ppl.

- go to an automotive store, buy 2 or 3 cans of Chrome spray paint, give each glass sheet 2 coats [on one side]

- Q: I rent, and my bedroom is a large attic conversionIt's very energy inefficient—I can feel heat loss through the ceiling even on a cool summer nightHow can I make it more energy efficient without making structural changes that will require my landlord's cooperation? I plan to put weatherstrip around the windows and I'm considering caulking the joists, but the only other thing I can think of is tacking blankets up on the walls and ceiling—a fire hazard, and not very elegant.

- Go get Immodium Advanced and take those, I think you take 2 and then 1 every loose stoolDrink lots of water and try eating foods that wont cause your stomach to ache, like try chicken soup and saltine crackersGet lots of rest too!

- Q: i need a low fat high protein atleast 30% high fiber 10% for a hedgehog

- On a traditional wet darkroom print, you would be using either the older oils with a brush (I believe Murphy's is a brand still sold at hobby shops) or some of the newer methods like photo-coloring pencils or spot-toner markersI have only ever seen spot-toning kits in gray scale, but it is possible that some markers are produced in a range of colors The easier way to do it in photoshop that's already been described is to purge the color information from your color picture and reset it, and then use the paintbrush set on color to get your desired effectsIf the photo is already in black and white, you can use the paintbrush without purging first (though, many artificial bw settings on cheaper digital cameras have lousy blacks, whicht can be improved slightly by purging all color information to make it a true black and white image)

- Q: I was wondering if anyone knew how to turn my hemp into oils, butter, fabric, yarn, or anything else possible?Also for knowledge purposes onlyI have heard that there are ways to increase the THC level of hemp plants, is that true?

- well, I would advise you to go to a doctor that prescribes, or recommends the use of medicinal marijuanaThere you will find out how to make your oils, butters, and how to use it for medicinal purposesOtherwise, you can google uses of hemp to find out what you can do, and how to do itI would certainly make sure you are legal though, before you do anything that might get you into trouble.

Send your message to us

Ceramic Fiber Blanket for Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords