Ceramic Fiber Blanket - Thermal Shock Resilient Insulation Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

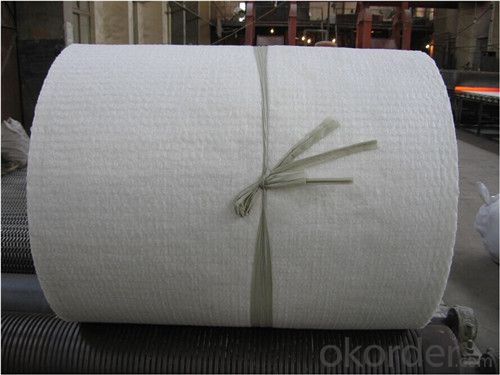

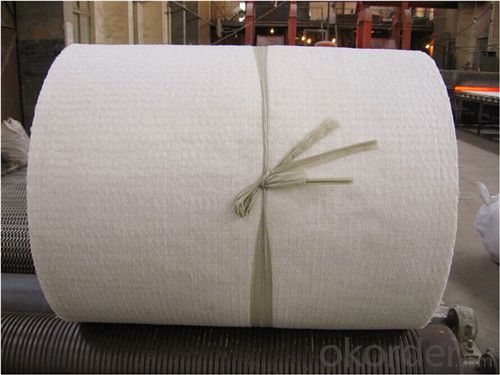

Ceramic Fibre Insulation Roll Resilient to Thermal Shock

Structure of Ceramic Fibre Insulation Roll Description

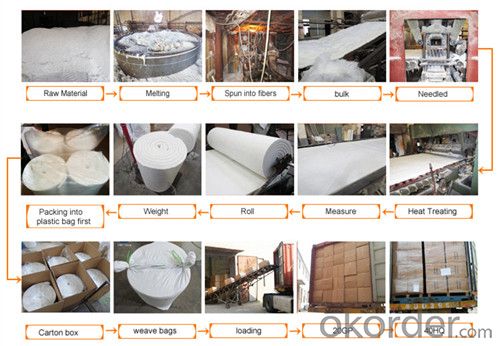

Ceramic Fibre is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic Fibre Insulation Roll has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of Ceramic Fibre Insulation Roll also has difference,and they are suitable for different workong temperatures.

Ceramic Fibre can be used after optional cutting .When Ceramic Fibre Insulation Roll storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Main Features of the Ceramic Fibre Insulation Roll

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Ceramic Fibre Insulation Roll

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

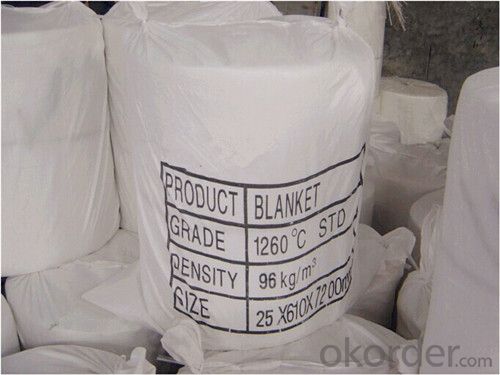

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

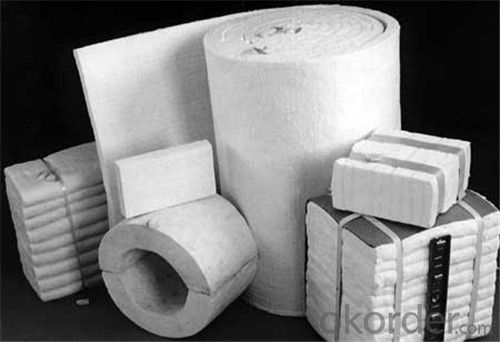

Ceramic Fibre Insulation Roll Images

◆Packaging

◆Product Process

Ceramic Fibre Insulation Roll Specification

Type | Ordinary | Standard | High Purity | High Aluminium | Zirconia | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | < 1000 | 1050 | 1100 | 1200 | 1350 | |

Color | white | spotlessly white | spotlessly white | spotlessly white | spotlessly white | |

Density (kg/m3) | 96 | 96 | 96 | 128 | 128 | |

Shrinkage on heating (%) (24 hours,density as 128/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.09(400°C) | 0.09(400°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) | 0.16(800°C) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

FAQ of Ceramic Fibre Insulation Roll

◆Can we accept OEM for Ceramic Fibre Insulation Roll?

YES! We can according your demand to produce.

◆Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: When we talk about textile yarns( cotton), what is meant by Open End yarn ( OE) and Ring Spun Yarn ( RS) .?Differentiate between the two types of yarnThanks.Anjan.

- Ring-spun yarn is a superior cotton yarn that results in a softer, more durable fabric than open-end yarnThe time-honored process of ring spinning requires two more processing steps than open-end yarn production and ring-spun yarn takes five times longer to produce.The additional steps involve continuously twisting and narrowing the rope of cotton fibersThis continuous fiber “helix” or twist gives ring-spun yarn extra softness and strengthThe resulting garments feel softer wash after wash.

- Q: I live in an old farmhouse, the loft (attic) was originally used to store grainI imagine it's a type of wattle and daub (probably spelt that wrong!) 'filling', with 15cm? terracotta tiles on topThe previous owners then put down a thin layer of cement on top of the tilesI want to insulate the loft using rolls of insulation 200mm thickPaper backed or not?

- Was too polite to say jackassm

- Q: I have REALLY thick red hair that is extremely courseI tried using many different products and have had my hair thinned and layered but it still looks frizzy and curly/wavyThe top is wavy and the ends curl a loti have tried straightening it and have used leave-in conditioners but it still looks frizzy and puffyI really want an some sort of emo look that looks good on meAny help would be greatly appreciated.

- Not until 105But have you taken some Aspirin or Tylenol? Because that should definitely bring it downIf it doesn't, then maybe go to the doctor's.

- Q: hey everybody .i've been researching alot and i couldn't seem to find the answer to this, The first one with a great answer and with details gets 10 points, please use heat terms, Thank you very much.you all rock!

- each babe is different!

- Q: My stomach, neck, shoulders, back, thighs and head hurt so badI'm on my period, and I'm in so much pain, I don't want to moveI'm extremely exhaustedMy thighs hurt so bad that they are numbI'm very noxious, any advice? Is this normal?

- whoa.I will have to wait for my husband to come home to answer that one.watch for him.railroaddave!!!!

- Q: how many yards of yarn are on a skien of red heart baby yarn?

- Anywhere from 115 to 210, as far as I recallThere may be more, now that they are also making larger skeins of yarnA skein of Red Heart can be anywhere from 3 - 8 (or now 16) ouncesThat's going to make a difference in how many yards are on it, of courseYou'll need to check the labelPhone a crafts or fabric storeThe clerk may be able to read the info for you over the phone.

- Q: Is there anything I can do to relieve constipation, that doesn't involve suppositories or prunes? I can't stand prunes, and I need to poo, not vomit, hahahaBut is there any foods or drinks that help? I drink between 6-15 full glasses of water a day, so liquids aren't a problemI need something that I can bring with me to class to munch on as well, so some things just won't work, like yogurt.

- if you want the widest set of options after graduation, go for mechanical engineeringyou can work in many fields with that degreethe most innovative would be electrical and or chemical engineering (choice depends on aptitude) civil is a field with lots of grunt work, but a field that never lacks for employment opportunitiesdo what you most like! many are called, but few get therehalf of all engineering students go on to study something else, but a grounding in any of the engineering fields will always serve you well.

- Q: At which temperature is the baby's health at risk? She is a little over a month now about 5 weeks oldI am concerned because my house is cold to me and I was wondering how the cold may effect her little hands, they're exposed because she like to keep them out of her blankets.

- make your cosmo 100 calories skinnier by mixing a raspberry infused vodka with club soda

- Q: knitting a mittenHELP pls.?

- i take advantage of those plastic rings that come on 6-packs of cokes and placed the threads i'm working with on it using larks headrelatively common to loosen the little knot and pull out the style of strands i chooseI open each skein of thread and decrease the finished element into working lengthsThen fold in a million/2 and larks head onto the plastic, (pull the tails interior the process the middle loop around the plasticI even have all left over strands and extra colours in zip lock luggage strung on slightly leather-basedI punched holes interior the back corner of the zip lock luggage and placed the wrapper with the colour extensive style on it interior the bag and the strands tied in loose over hand pull knotI shop all those factors to boot as a velvety hand towel in a heavy procuring bagThe velvety hand towel is sensible to place the threaded needles in and fold up once I would desire to give up working in this for a on a similar time asThe heavy procuring bag will cling on a hook interior the closet waiting for me to come again to artwork.

- Q: My house is facing E-W and getting direct sun all day here in FloridaI just finished siding last Sumer by using a insulation with tight dead air space, my bed room window facing the East has blind shut all day to block the sun, however, my bed room gets hotter than the rest of the room, plus entire indoor house is hotter than even out side especially in the eveningWhy is this, and what can I do ? (do not wish to spend money too much since I just finish putting $30K into this home.

- Get the insulation done firstYou can do the quick fixes to the windows yourself to help stop the air leaks until you can afford to have them replacedSome caulk and weather stripping won't cost you a lot and you should be able to complete it in a weekend or two depending on the number of windows you have.

Send your message to us

Ceramic Fiber Blanket - Thermal Shock Resilient Insulation Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords