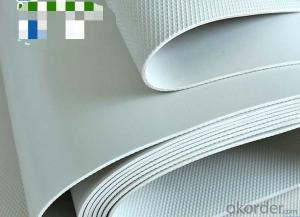

PVC Puncture Resistant Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

Product Features

low -cost ,anti-aging ,anti -ultraviolet proformance ,shrinkage rate is high ,low temperature flexibility is good

Physical Property

1. Exposed to sunshine: UV rays resistance, long service life and aging resistance

2. Easy installation and dimensional stability: can be wieldable under wide range of temperature and experience minus dimensional change in thermal treatment

3. High tensile strength and elongation thus can accommodate movements of substrates

4.Good flexibility under low temperature, good adaptability to ambient temperature difference

5, Secure anti-puncture and good rooting resistance, no pollution caused to environment when being welded and good waterproofing choice for plant roofs

6. Good plasticity: convenient and fast treatment of detailed parts of corners and edges

Scope of Application:

1. The waterproofing of the Industrial or civil construction's roof, including the planting roof,

flat roof, sloping roof.

2. Waterproofing of the underground building: Including reservoirs, dams, canals, and all parts

of the basement water seepage.

3. Tunnel, granary, civil air defense projects, garbage landfills, and other man-made lake.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can waterproofing membranes be used on mechanical equipment rooms?

- Waterproofing membranes are suitable for application in mechanical equipment rooms. These membranes have been specifically designed to create a protective barrier, safeguarding against water penetration and preventing any potential harm caused by moisture to the underlying structures. The installation of these membranes within mechanical equipment rooms, which often house valuable and sensitive machinery, proves advantageous as it ensures the durability and functionality of the equipment. By applying waterproofing membranes to the walls, floors, and ceilings of these rooms, it effectively prevents water leaks, moisture accumulation, and any potential harm resulting from water infiltration. This is particularly crucial in regions that experience heavy rainfall, high humidity, or possess a high water table. Additionally, the use of waterproofing membranes aids in regulating condensation and discouraging the growth of mold, both of which could adversely impact the performance of mechanical equipment. In summary, the utilization of waterproofing membranes in mechanical equipment rooms offers a practical and efficient solution for equipment protection and the maintenance of optimal performance.

- Q: Are waterproofing membranes resistant to gas and vapor transmission?

- Waterproofing membranes are generally resistant to the transmission of gas and vapor, which is important in preventing moisture and potentially harmful substances from entering the structure. These membranes act as a barrier against water and are typically made from materials like synthetic rubber, thermoplastic, or bitumen, which have low permeability to gases and vapors. To further enhance their resistance, additives or additional layers are often incorporated. By utilizing waterproofing membranes, one can effectively create a durable barrier against water, gases, and vapors in different construction applications.

- Q: Can a waterproofing membrane be used for modular buildings or container homes?

- Yes, a waterproofing membrane can be used for modular buildings or container homes. These structures often have unique challenges when it comes to waterproofing due to their modular construction and potential for water ingress at joints and connections. A waterproofing membrane can effectively seal these areas, preventing leaks and water damage. It can be applied to the exterior walls, roof, and foundation of the structure, providing a durable and long-lasting waterproof barrier. Additionally, a waterproofing membrane can be customized to meet the specific requirements of modular buildings and container homes, ensuring optimal protection against water infiltration.

- Q: Can a waterproofing membrane be used in areas with heavy foot traffic?

- Yes, a waterproofing membrane can be used in areas with heavy foot traffic. In fact, many waterproofing membranes are specifically designed to withstand heavy use and abuse, making them ideal for high-traffic areas such as walkways, balconies, and parking decks. These membranes are typically made from durable materials like rubber, PVC, or modified bitumen, which are resistant to wear and tear. Additionally, some membranes have a slip-resistant surface to improve safety in areas where people are walking. It's important to choose a waterproofing membrane that is suitable for the specific application and meets the required durability standards to ensure long-lasting protection in areas with heavy foot traffic.

- Q: Can waterproofing membranes be used on underground structures?

- Yes, waterproofing membranes can be used on underground structures.

- Q: Sbs waterproof sheet and app coil how to see it

- SBS full name is: styrene - butadiene - styrene block copolymer. SBS is an abbreviation of elastomer modified asphalt waterproofing membrane. It is also known as SBS modified asphalt waterproofing membrane. It is made of polyester felt, fiberglass felt or glass fiber reinforced polyester felt as the base, styrene-butadiene (SBS) thermoplastic elastomer as a petroleum asphalt modifier, both sides covered with isolation materials made of building waterproofing membrane, the product implementation of the standard GB18242 national mandatory standards. Product markings are carried out according to the following procedures: name, model, tire base, upper surface material, lower surface material, thickness, area and this standard number, for example: 3mm thick, 10㎡ area, the upper surface is mineral pellets, the lower surface is poly Vinyl film, polyester tread base, type I elastomer modified asphalt waterproofing membrane marked as: SBS I PY M PE 3 10 GB18242-2008.

- Q: What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can vary depending on the specific type and quality of the membrane, as well as the severity and frequency of the weather conditions it is exposed to. However, high-quality waterproofing membranes are designed to withstand extreme weather conditions for an extended period, typically ranging from 10 to 20 years or more. Regular maintenance and inspections can help prolong the lifespan of the membrane and ensure its effectiveness in challenging weather conditions.

- Q: Can a waterproofing membrane be applied in cold weather or during winter months?

- Yes, a waterproofing membrane can be applied in cold weather or during winter months. However, there are specific considerations and precautions that need to be taken into account. It is important to choose a waterproofing membrane that is specifically designed for cold weather applications. These membranes are formulated to withstand low temperatures and provide effective waterproofing even in freezing conditions. Before applying the membrane, the surface should be thoroughly cleaned and free from any debris, ice, or snow. It is also crucial to ensure that the surface is dry, as moisture can affect the adhesion and performance of the membrane. In cold weather, it may take longer for the surface to dry, so extra time should be allowed for this process. Additionally, the ambient temperature during the application should be within the recommended range specified by the manufacturer. Cold temperatures can affect the curing time of the membrane and may require longer curing periods. It is important to follow the manufacturer's instructions and guidelines for application and curing to ensure proper performance. Moreover, it is advisable to consult with a professional waterproofing contractor who has experience working in cold weather conditions. They can provide expert guidance and ensure that the membrane is applied correctly to achieve the desired waterproofing results. Overall, while it is possible to apply a waterproofing membrane in cold weather or during winter months, it is crucial to choose the right product, prepare the surface properly, and follow the manufacturer's instructions and guidelines to ensure a successful and effective application.

- Q: Can a waterproofing membrane be used for industrial applications?

- Yes, a waterproofing membrane can be used for industrial applications. Waterproofing membranes are designed to provide a barrier against water penetration and can be utilized in various industrial settings such as factories, warehouses, and manufacturing facilities to protect against water damage and maintain the integrity of the infrastructure.

- Q: Can a waterproofing membrane be used for residential swimming pools?

- Indeed, residential swimming pools can benefit from the use of a waterproofing membrane. These membranes are frequently employed in construction to safeguard against water infiltration and can be utilized on diverse surfaces including concrete, tile, and metal. By forming a barrier, they effectively prevent water from permeating the pool structure, thereby preserving its integrity and averting leaks. Furthermore, waterproofing membranes afford protection against other types of harm such as corrosion and deterioration resulting from chemicals or adverse weather conditions. Consequently, it is crucial to choose a top-notch waterproofing membrane specifically designed for swimming pool applications in order to guarantee long-lasting safeguarding and durability.

Send your message to us

PVC Puncture Resistant Waterproof Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords