PVC Root Puncture Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification

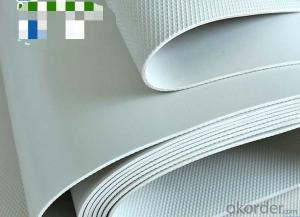

Item | Specification |

Length | 20m |

Width | 1.05m, 2.05m,2.1m |

Thickness | 0.8mm,1.0mm;1.2mm;1.5mm;2.0mm |

Product Information

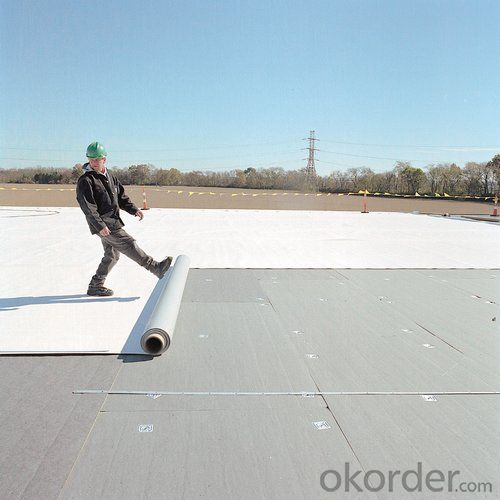

PVC roofing membrane is a highly-engineered,new-type membrane manufactured

using polyvinyl chloride as main materials and added other chemicals such as anti-oxidant,anti-UV materials to make it flexible,stable and UV-resistant.

Product Features

1. No pollution to the environment;

2. Fine tensile strength,elasticity,no deformation under hot or

cold temperature conditions;

3. Easily welding,firm and secure;re-weldable after weathering within their lifetime;

4. Fine resistance to static electricity;

5. Fine resistance to UV ;

6. Root-resistance and suitable for planting roofs;

7. Fine resistance to weathering and ageing;

8. Keep good flexibility under low temperature;

9. Fine puncture resistance,joint peel strength and joint shear strength property;

10. Easy treatments on delicate parts of corners and edges.

Application Range

PVC membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are waterproofing membranes suitable for residential basements?

- Residential basements can indeed benefit from the use of waterproofing membranes. These membranes are specifically engineered to avert water infiltration and safeguard the basement against any harm caused by moisture. Whether applied on the interior or exterior walls, they create a formidable barrier against both water and dampness. This, in turn, helps to stave off problems like mold growth, water damage, and structural decay. With their excellent durability and ability to foster a dry and wholesome living space, waterproofing membranes emerge as a highly effective solution for residential basements.

- Q: Can a waterproofing membrane be used for a commercial building roof?

- Yes, a waterproofing membrane can be used for a commercial building roof. Waterproofing membranes are commonly used in commercial buildings to protect the roof from water damage and leaks. These membranes are typically made from synthetic materials such as PVC or EPDM, which are highly durable and resistant to water penetration. They are installed as a protective layer on the roof surface, effectively preventing water from seeping through and causing damage to the building. Additionally, waterproofing membranes are designed to withstand various weather conditions, including heavy rain, snow, and UV exposure, making them suitable for commercial buildings that are exposed to harsh environmental elements. The use of a waterproofing membrane is an effective and long-lasting solution for ensuring the integrity and longevity of a commercial building roof.

- Q: Can a waterproofing membrane be used for stadiums and sports arenas?

- Yes, a waterproofing membrane can be used for stadiums and sports arenas. These large structures are exposed to various weather conditions and are prone to water damage. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can be applied to different parts of the stadium or sports arena, such as the roof, walls, and foundation. By preventing water from entering the structure, a waterproofing membrane helps to maintain the integrity of the building, prolong its lifespan, and prevent costly repairs due to water damage. Additionally, these membranes can also provide insulation and energy-saving benefits, further enhancing the overall performance of the stadium or sports arena.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Yes, a waterproofing membrane can be used on adobe block surfaces. Adobe blocks are made from a mixture of clay, sand, and straw, which can be susceptible to water damage. Applying a waterproofing membrane can help prevent water penetration and protect the adobe blocks from moisture-related issues such as cracking, erosion, or mold growth. It is important to ensure that the waterproofing membrane is compatible with adobe surfaces and follows the manufacturer's guidelines for application. Additionally, proper surface preparation and repair of any existing damage is crucial before applying the membrane to ensure its effectiveness.

- Q: Can a waterproofing membrane be used in areas with high levels of moisture and humidity?

- Yes, a waterproofing membrane can be used in areas with high levels of moisture and humidity. Waterproofing membranes are specifically designed to protect surfaces from water penetration, making them ideal for areas with high moisture content. These membranes are typically made from materials like rubber, PVC, or bitumen, which are resistant to water and can effectively prevent water from seeping through. Additionally, some waterproofing membranes also have built-in features such as vapor barriers or breathable properties, allowing them to be used in areas with high humidity levels. However, it is important to choose the right type of waterproofing membrane that is suitable for the specific conditions and requirements of the area to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane be used in ponds or reservoirs?

- Ponds and reservoirs can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier against water, effectively preventing leaks and seepage. They are commonly employed in various water containment applications, including ponds, reservoirs, and other water storage structures. Waterproofing membranes are typically constructed from durable materials such as rubber, PVC, or HDPE (high-density polyethylene). These materials exhibit resistance to UV radiation, chemicals, and other environmental factors that could compromise the membrane's integrity. As a result, they provide long-lasting protection, effectively preventing water from penetrating the structure. The installation process for a waterproofing membrane in a pond or reservoir involves careful surface preparation, followed by the application of the membrane using suitable adhesives or welding techniques. The membrane is typically applied to the entire surface area, including the walls and base of the structure, ensuring complete water tightness. The utilization of a waterproofing membrane in ponds or reservoirs offers several benefits. It helps to maintain the water level by preventing evaporation and leakage, which is particularly crucial in arid regions where water scarcity is a concern. Additionally, it safeguards the surrounding soil from water contamination and prevents the loss of valuable water resources. However, it is essential to note that the selection of the appropriate waterproofing membrane should be based on the specific requirements of the pond or reservoir. Factors such as the structure's size, the type of water it will hold, and the environmental conditions should be taken into consideration when choosing the most suitable membrane. In conclusion, a waterproofing membrane is a reliable and long-lasting solution for water containment and prevention of leaks in ponds or reservoirs. By ensuring proper installation and maintenance, it can guarantee the integrity and sustainability of the water storage structure.

- Q: Can a waterproofing membrane be used for warehouses or storage facilities?

- Yes, a waterproofing membrane can be used for warehouses or storage facilities. It provides an effective barrier against water penetration, helping to protect the building and its contents from moisture damage.

- Q: Can a waterproofing membrane be used for a water tank liner?

- Indeed, a water tank liner can utilize a waterproofing membrane. The main purpose of waterproofing membranes is to obstruct water infiltration and can be employed on various surfaces, such as concrete, metal, and other commonly used materials in water tank construction. These membranes establish a barrier that thwarts leakage, cracks, and other types of water harm, thus guaranteeing the water tank's strength and durability. Moreover, waterproofing membranes are usually flexible, enabling them to adapt to the tank's shape and accommodate any potential movement or settlement. However, it is crucial to select a waterproofing membrane specifically engineered for water tank applications to ensure optimal performance and long-lastingness.

- Q: Can a waterproofing membrane be used on terrazzo surfaces?

- Yes, a waterproofing membrane can be used on terrazzo surfaces. Terrazzo is a durable and long-lasting material, but it is porous and can absorb water if left untreated. Applying a waterproofing membrane helps protect the terrazzo surface from moisture damage, preventing water penetration and potential issues such as staining, cracking, or mold growth.

- Q: Can a waterproofing membrane be certified or approved by industry organizations?

- Yes, a waterproofing membrane can be certified or approved by industry organizations. There are various industry organizations and standards bodies that evaluate and certify building materials and products, including waterproofing membranes. These certifications or approvals ensure that the membrane meets specific quality and performance standards set by the industry. Industry organizations such as the International Organization for Standardization (ISO), Underwriters Laboratories (UL), and the American Society for Testing and Materials (ASTM) often provide certifications or approvals for waterproofing membranes. These certifications involve rigorous testing and evaluation of the membrane's physical properties, such as its ability to resist water penetration, durability, and compatibility with other building materials. Certifications or approvals from industry organizations provide assurance to consumers, architects, contractors, and building owners that the waterproofing membrane has undergone testing and meets recognized standards for quality and performance. They also help in building code compliance and may be required for certain projects. It is always advisable to look for waterproofing membranes that have been certified or approved by reputable industry organizations to ensure that you are using a reliable and effective product for your waterproofing needs.

Send your message to us

PVC Root Puncture Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords