EPDM Waterproofing Membrane for Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

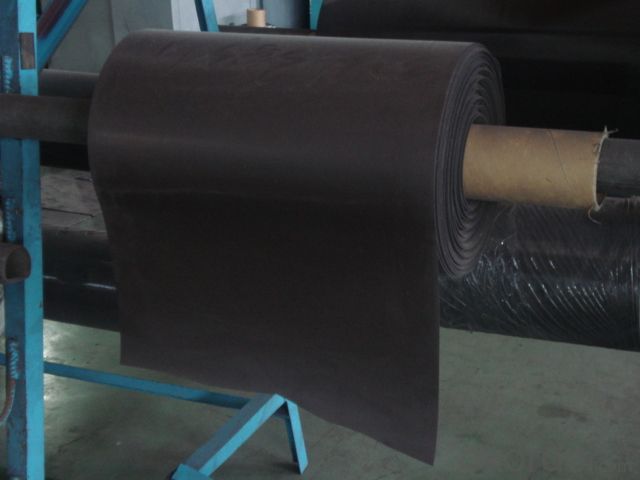

1.EPDM Waterproof Membrane / Roofing Material / Sheets Roofing

2.High tensile strength.

3.Good elongation.

4.UV resistant.

5.Anti-corrosion.

Product instruction

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features

1) Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Application

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Introduction for EPDM Waterproofing Membrane:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for solar panel installations?

- Yes, a waterproofing membrane can be used for solar panel installations. Waterproofing membranes are commonly used in construction to create a watertight barrier. When properly installed, they can effectively protect the underlying structure and prevent water leakage. This makes them a suitable option for protecting solar panel installations from potential water damage.

- Q: Can a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth. By creating a barrier that prevents water from seeping into the walls or floors, it reduces the moisture content in the environment, which is necessary for mold and mildew to thrive. This can effectively prevent their growth and minimize the potential for related health issues and structural damage.

- Q: Can a waterproofing membrane be used on concrete tanks?

- Yes, a waterproofing membrane can be used on concrete tanks. Waterproofing membranes are commonly used to prevent water leakage and provide protection against water ingress in various structures, including concrete tanks. These membranes create a barrier that prevents water from penetrating the concrete surface, ensuring the tank remains watertight and protected against moisture damage.

- Q: How does a waterproofing membrane handle water pressure from adjacent structures?

- A waterproofing membrane is designed to handle water pressure from adjacent structures by acting as a barrier that prevents water from seeping through. It resists the force exerted by the water pressure and ensures that no water can penetrate into the protected area.

- Q: Can a waterproofing membrane be used on stucco surfaces?

- Yes, a waterproofing membrane can be used on stucco surfaces. Waterproofing membranes are often applied to stucco surfaces to protect them from water damage and enhance their durability. These membranes create a barrier that prevents water from seeping into the stucco, helping to maintain its integrity and preventing moisture-related issues such as cracking or mold growth.

- Q: Can a waterproofing membrane be used for swimming pool coping?

- Using different grammar and expressions: Using a waterproofing membrane for swimming pool coping is not possible. Coping is the term used for the material that covers the upper edges of the pool walls, usually made of concrete, stone, or tile. Its main purposes are to provide a polished appearance and shield the pool structure from water damage. Conversely, a waterproofing membrane is a substance applied to a structure's surface, such as a basement or roof, to prevent water infiltration. Although both serve the same purpose of water protection, they are specifically designed for distinct applications and cannot be interchanged.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on precast concrete surfaces. Firstly, the surface must be thoroughly cleaned and free from any dirt, debris, or loose particles. It is also important to ensure that the precast concrete surface is dry before applying the membrane. Additionally, the type of waterproofing membrane used should be compatible with the precast concrete material to ensure proper adhesion. Proper surface preparation, material compatibility, and ensuring a dry surface are key factors to consider when installing a waterproofing membrane on precast concrete surfaces.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures or tears. It is typically made from durable materials such as PVC, TPO, or EPDM, which are known for their strength and resistance to damage. These membranes undergo rigorous testing to ensure their ability to withstand various environmental conditions and potential sources of punctures or tears, such as sharp objects or heavy foot traffic. Additionally, some waterproofing membranes come with reinforcement layers or added protection to further enhance their puncture and tear resistance. However, it is important to note that while waterproofing membranes are highly resilient, they are not completely impervious to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help maximize its longevity and performance.

- Q: Are waterproofing membranes resistant to root penetration?

- Waterproofing membranes are generally resistant to root penetration. They are designed specifically to prevent water from penetrating through the surface and reaching the underlying structure. Apart from their ability to resist water, they also possess qualities that make them resistant to root penetration. This is crucial in areas with vegetation or trees, as roots can potentially grow and damage various surfaces, compromising the integrity of the waterproofing system. Waterproofing membranes are typically made from tough and durable materials, creating a barrier that roots find difficult to penetrate. However, it is important to acknowledge that no waterproofing membrane is completely impervious to root penetration, especially if the root systems are particularly aggressive or invasive. In such cases, additional measures such as root barriers or specialized membranes may be necessary to ensure long-term protection against root penetration.

- Q: Can a waterproofing membrane be used for chemical storage facilities?

- Yes, a waterproofing membrane can be used for chemical storage facilities. It provides an effective barrier against moisture and can help prevent leaks or spills from contaminating the surrounding environment. However, it is important to ensure that the membrane is compatible with the specific chemicals being stored to avoid any potential chemical reactions or degradation of the membrane itself. Additionally, proper ventilation and safety measures should be in place to address any potential chemical hazards.

Send your message to us

EPDM Waterproofing Membrane for Roof Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords