EPDM Waterproofing Membrane for Roofing Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product instruction

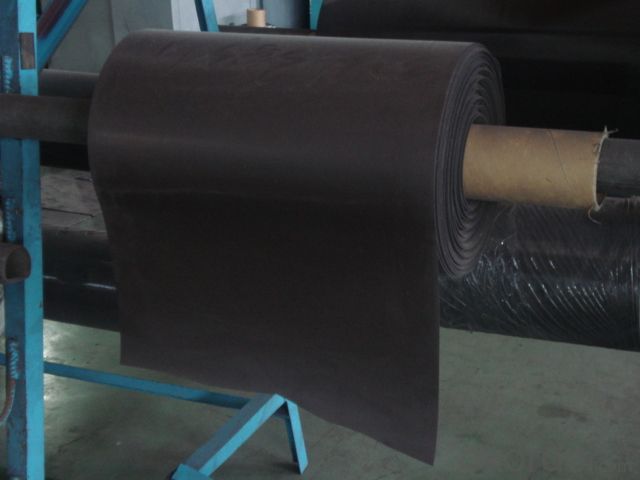

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Detailed Product Description

Product Name: High Polymer Waterproof Membrane

Width of roll: 1m; Thickness : 0.5mm , 1mm , 1.5mm,

Area of roll : 15sq.m , 10sq.m , 7.5sq.m;

Low temperature flexibility : -18/-25

Surfaced materials : PE film , granule, slate , metal foil , sand , mineral and etc;

Applications: Bridge building, storage, road, tunnel, parking station, swimming pool, water-disposal pool, rubbish-disposal places and other waterproofing project, especially for,easy broken structural and cold building protective;

Features

1) Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Application

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Introduction for EPDM Waterproofing Membrane:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for retaining walls?

- A waterproofing membrane is suitable for retaining walls as it helps to prevent water from penetrating and causing damage or structural failure. These membranes, made of materials like rubber, PVC, or bituminous compounds, are installed on the inner side of the retaining wall to create a barrier against water infiltration. In addition to protecting the wall's stability, some membranes also offer resistance to root penetration, UV protection, and flexibility to accommodate movement. However, it is crucial to consider factors such as the type of retaining wall, water pressure, and local climate conditions when selecting the right waterproofing membrane. It is advisable to consult with a professional engineer or contractor to ensure the most suitable waterproofing solution for your specific retaining wall project.

- Q: It is good for black roof with waterproof paper

- No film or PE film (black surface) coil is generally not used for the roof; if the roof is often on the need to lay in the coil above the 5 cm thick cement mortar to do the protective layer or the choice of sand and shale surface waterproof Coil. Lough membrane (silver surface) The role of the membrane to play the radiation can be used directly for the roof without any protection.

- Q: Are waterproofing membranes resistant to gas and vapor transmission?

- Yes, waterproofing membranes are generally resistant to gas and vapor transmission. These membranes are designed to create a barrier that prevents the passage of liquid water, as well as gases and vapors, effectively ensuring the protection and integrity of the structure they are applied to.

- Q: Can a waterproofing membrane be used on gypsum board surfaces?

- Yes, a waterproofing membrane can be used on gypsum board surfaces. Gypsum board, also known as drywall, is a common material used in interior construction. While it is not inherently waterproof, applying a waterproofing membrane can help protect the gypsum board from moisture damage. A waterproofing membrane is a thin layer of material that is applied to the surface of the gypsum board. It forms a barrier that prevents water from seeping into the board and causing it to deteriorate or mold. It can be used in areas where moisture is present, such as bathrooms, kitchens, laundry rooms, or basements. Before applying a waterproofing membrane, it is important to prepare the gypsum board surface properly. This may involve cleaning the surface, patching any holes or cracks, and ensuring the board is dry and free of dust. Once the surface is ready, the waterproofing membrane can be applied according to the manufacturer's instructions. It is worth noting that while a waterproofing membrane can provide some protection against moisture, it is not a guarantee against water damage. It is always important to address the source of water intrusion and ensure proper drainage and ventilation in any area prone to moisture. Additionally, it is recommended to consult with a professional or follow the manufacturer's recommendations when choosing and applying a waterproofing membrane to gypsum board surfaces.

- Q: Can waterproofing membranes be used for planter boxes?

- Yes, waterproofing membranes can be used for planter boxes. Waterproofing membranes provide a protective barrier against moisture, preventing any water leakage that could damage the planter box or surrounding areas. This helps to preserve the longevity and integrity of the planter box, making it suitable for long-term use in outdoor environments.

- Q: Does a waterproofing membrane need to be primed before installation?

- Yes, a waterproofing membrane typically requires priming before installation. Priming helps improve the adhesion of the membrane to the substrate and ensures proper bonding, enhancing the overall effectiveness and durability of the waterproofing system.

- Q: Can a waterproofing membrane be used on vinyl surfaces?

- Yes, a waterproofing membrane can be used on vinyl surfaces. Vinyl surfaces, such as vinyl flooring or vinyl siding, are commonly found in many residential and commercial buildings. Waterproofing membranes are designed to create a barrier against water and moisture, preventing them from seeping into the underlying materials. These membranes can be applied over vinyl surfaces to provide an additional layer of protection, ensuring that the vinyl remains unaffected by water damage or deterioration. It is important to select a waterproofing membrane that is compatible with vinyl surfaces and follow the manufacturer's instructions for proper application.

- Q: Can a waterproofing membrane be used on precast stone block surfaces?

- Yes, a waterproofing membrane can be used on precast stone block surfaces. A waterproofing membrane is designed to provide a protective barrier against water infiltration, and it can be applied to various surfaces, including precast stone blocks, to prevent water damage and ensure the longevity of the structure.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Yes, waterproofing membranes can be used on stormwater management systems. Waterproofing membranes are commonly used to prevent water infiltration and protect structures from water damage. In the case of stormwater management systems, which are designed to capture, store, and manage rainwater runoff, waterproofing membranes can be used to create a watertight seal and prevent leaks or seepage. Stormwater management systems often include components such as retention ponds, infiltration basins, or underground storage systems. These components need to be properly sealed to ensure that the collected stormwater is contained and managed effectively. Waterproofing membranes, when installed correctly, can provide an impermeable barrier that prevents water from escaping or infiltrating the system. Using waterproofing membranes on stormwater management systems offers several benefits. Firstly, it helps to maintain the integrity and functionality of the system by preventing leaks or seepage that may compromise its performance. This ensures that the stormwater is effectively captured and managed, reducing the risk of flooding or erosion. Additionally, waterproofing membranes can extend the lifespan of stormwater management systems by protecting them from water damage. Water infiltration can lead to structural deterioration, corrosion, or the growth of mold and mildew, which can all weaken the system over time. By creating a waterproof barrier, the membranes help to preserve the structural integrity of the components, increasing their longevity and reducing maintenance requirements. Furthermore, using waterproofing membranes on stormwater management systems can also contribute to environmental sustainability. By effectively containing and managing stormwater runoff, these systems help to reduce water pollution and improve the quality of natural water bodies. Waterproofing membranes play a crucial role in preventing stormwater from carrying pollutants, such as chemicals or sediment, into rivers, lakes, or oceans. In summary, waterproofing membranes can be used on stormwater management systems to create a watertight seal, prevent leaks, and protect the components from water damage. By providing an impermeable barrier, these membranes help to maintain the functionality and integrity of the system, extend its lifespan, and contribute to environmental sustainability by reducing water pollution.

- Q: Are waterproofing membranes resistant to alkalis?

- Yes, waterproofing membranes are generally resistant to alkalis.

Send your message to us

EPDM Waterproofing Membrane for Roofing Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords