Firestone Epdm

Firestone Epdm Related Searches

Electric Fireplace Faux Stone Medium Duty Firebrick Electric Fireplace Media Center Real Flame Electric Fireplace Home Depot Electric Fireplace Esd Epoxy Disposable Electronic Shisha Fireplace Heat Exchanger Electrical Distribution Block Electric Fireplaces Montreal Fireplace Damper Electric Indoor Fireplaces Electric Fireplace With Stand Epc Electrical Connectors Affordable Electric Fireplaces Fire Clay Decorative Electric Fires Indoor Fireplaces ElectricFirestone Epdm Supplier & Manufacturer from China

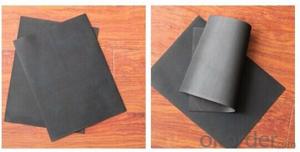

Firestone EPDM is a high-quality synthetic rubber roofing product that is widely recognized for its durability and weather resistance. This product is designed to provide long-lasting protection for various types of buildings, including residential, commercial, and industrial structures. The EPDM roofing system from Firestone is known for its flexibility, UV resistance, and ability to withstand extreme temperatures, making it a popular choice for many applications.Firestone EPDM is commonly used in both new construction and re-roofing projects, offering a reliable and cost-effective solution for a wide range of roofing needs. Its seamless design helps to prevent leaks and water damage, while its resistance to harsh weather conditions ensures that the roof remains in good condition for many years. This product is also environmentally friendly, as it can be easily recycled and does not contribute to urban heat island effects.

Okorder.com is a leading wholesale supplier of Firestone EPDM products, offering a vast inventory to meet the needs of contractors, builders, and homeowners alike. With a commitment to providing high-quality materials at competitive prices, Okorder.com ensures that customers have access to the best EPDM roofing solutions available on the market. By partnering with Firestone, Okorder.com can guarantee that customers receive the most reliable and durable roofing products, backed by the reputation of a trusted brand.

Hot Products