Rpe Geomembrane

Rpe Geomembrane Related Searches

Rpp Geomembrane Gse Geomembrane Pe Geomembrane Tpo Geomembrane Gse Hdpe Geomembrane Plastic Geomembrane Geomembrane Hdpe Geomembrane In Hdpe Reinforced Hdpe Geomembrane Pvc Geomembrane Raven Geomembrane Trp Geomembranes Reinforced Geomembrane Rpp Geomembrane Liner Geomembranes Geomembrane Material Permeable Geomembrane Geomembrane Film Geomembrane Pdf Geomembrane Properties Bgm Geomembrane Hdpe Textured Geomembrane Wholesale Geomembrane Hdpe China Pvc Geomembrane Wholesale Geomembrane Wholesale Hdpe Geomembrane Geomembrane Machine China Geomembrane Epi Geomembrane Hdpe Geomembrane ChinaRpe Geomembrane Supplier & Manufacturer from China

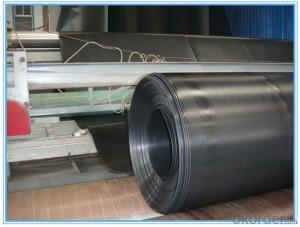

Rpe Geomembrane is a high-performance waterproofing and lining material, designed for various applications in civil engineering, environmental protection, and construction projects. It is known for its durability, flexibility, and resistance to chemicals and UV radiation, making it an ideal choice for a wide range of projects. The product is manufactured using advanced technology to ensure optimal quality and performance, providing a reliable solution for waterproofing and containment applications.Rpe Geomembrane is widely used in applications such as landfill liners, water reservoirs, canal lining, and pond liners. It is also employed in the construction of tunnels, dams, and other infrastructure projects where waterproofing and protection from environmental elements are crucial. The product's versatility allows it to be tailored to specific project requirements, offering a customized solution for each unique scenario. Its ability to withstand harsh conditions and resist degradation over time makes it a preferred choice among engineers and contractors.

Okorder.com is a leading wholesale supplier of Rpe Geomembrane, offering a vast inventory of this high-quality product. As a reputable supplier, Okorder.com ensures that customers receive the best possible products at competitive prices. With a commitment to customer satisfaction, Okorder.com provides efficient and reliable service, ensuring that orders are processed and delivered promptly. By partnering with Okorder.com, customers can be confident that they are receiving the best Rpe Geomembrane products for their projects, backed by a strong supply chain and exceptional customer support.

Hot Products