SBS Elastomer Modified-bitumen Waterproof Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

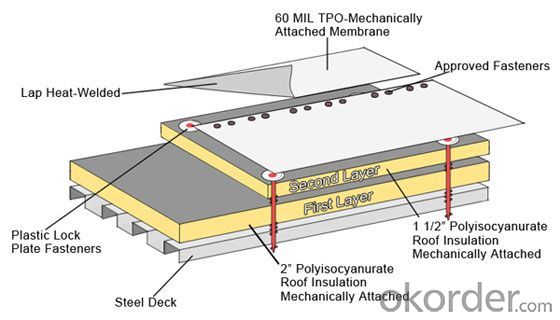

sbs waterproof membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

Application

The needle-punched polyester is widely used as the carrier for waterproofing membrane production. The membrane made withneedle-punched polyester matis widely used for: Construction waterproofing; Moisture-proof in roof engineering, underground engineering, indoor ground, etc;Corrosion resistance for water pool or building bases.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

product show

FAQ

- Q: Can a waterproofing membrane be used in steam rooms?

- Indeed, the utilization of a waterproofing membrane within steam rooms is possible. This specialized membrane is crafted to obstruct water infiltration and is commonly employed in areas where moisture is prevalent, such as bathrooms, showers, and steam rooms. The primary function of this membrane is to create a barrier that hinders water vapor from penetrating the underlying structure and inducing harm. In the case of steam rooms, where elevated levels of humidity and moisture are abundant, the implementation of a waterproofing membrane is imperative in safeguarding the walls, floors, and other surfaces from water damage and the growth of mold. It is of utmost importance to select a waterproofing membrane that is explicitly designed for environments with high moisture content, such as steam rooms, in order to ensure sufficient protection and durability. Furthermore, for the membrane to effectively fulfill its purpose within a steam room setting, proper installation and adherence to the guidelines provided by the manufacturer are essential.

- Q: Are waterproofing membranes resistant to fire?

- No, waterproofing membranes are not inherently resistant to fire.

- Q: Is a waterproofing membrane resistant to cracking or shrinking?

- Typically, a waterproofing membrane resists cracking and shrinking. Its purpose lies in creating a barrier that prevents water from penetrating surfaces like roofs, walls, or foundations. To accomplish this, these membranes are typically constructed from flexible and durable materials, such as modified bitumen, PVC, EPDM, or polyurethane. These materials possess inherent properties that enable them to withstand different environmental conditions, including temperature fluctuations, UV radiation, and physical stresses. This resilience guarantees that the waterproofing membrane remains intact and stable, even when exposed to challenging circumstances. Furthermore, waterproofing membranes are engineered to be highly resistant against cracking and shrinking. They are designed to accommodate movements and structural changes that may arise in the building or substrate over time. This flexibility helps prevent the membrane from cracking or tearing, even in the presence of minor shifts or settling in the structure. Additionally, waterproofing membranes undergo rigorous testing and quality control measures during their manufacturing process. These tests replicate real-world conditions, including temperature changes, elongation, and compression, to verify the membrane's performance and durability. Nevertheless, it is vital to note that the quality and performance of a waterproofing membrane can vary depending on the specific product and manufacturer. Selecting a reliable and reputable brand, as well as ensuring proper installation and maintenance, is crucial to maximize the membrane's resistance to cracking or shrinking.

- Q: Does a waterproofing membrane prevent efflorescence or mineral deposits on surfaces?

- Yes, a waterproofing membrane can help prevent efflorescence or mineral deposits on surfaces. The membrane acts as a barrier, preventing water from entering the surface and carrying dissolved minerals or salts that cause efflorescence. By keeping the surface dry, the membrane helps to minimize the formation of mineral deposits.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- Yes, a waterproofing membrane can help prevent mold or mildew growth by creating a barrier that keeps moisture out. By stopping water infiltration, it reduces the conditions necessary for mold and mildew to thrive, thus providing protection against their growth.

- Q: How does a waterproofing membrane handle movement of a building due to settling or seismic activity?

- A waterproofing membrane is designed to handle movement of a building caused by settling or seismic activity by providing flexibility and elasticity. It can accommodate small shifts and vibrations without cracking or breaking, ensuring that the waterproof barrier remains intact. The membrane's ability to stretch and contract helps it to adapt to the movement of the structure, preventing water intrusion and maintaining its effectiveness in safeguarding the building against moisture damage.

- Q: Can waterproofing membranes be used on retaining walls?

- Retaining walls can indeed benefit from the application of waterproofing membranes. It is quite common to utilize these membranes on retaining walls in order to hinder the infiltration of water and safeguard the structure against issues arising from moisture, such as seepage, efflorescence, and cracking. These membranes act as a barrier, effectively preventing water from permeating the retaining wall and causing harm. Typically, they are installed on the exterior side of the retaining wall, providing an added layer of protection against water intrusion. There is a wide range of waterproofing membranes available, including sheet membranes, liquid-applied membranes, and cementitious coatings, allowing for the selection of the most suitable option based on the specific requirements and demands of the retaining wall.

- Q: Can a waterproofing membrane be used in geotechnical applications?

- Indeed, geotechnical applications can make effective use of waterproofing membranes. These membranes are commonly employed to safeguard structures against water infiltration and are applied to various surfaces such as roofs, basements, and foundations. In geotechnical applications, these membranes serve the purpose of preventing water from seeping into the soil, thus averting erosion and stabilizing slopes. They can be positioned either horizontally or vertically to establish a barrier that hinders water penetration, which proves particularly advantageous in retaining walls, embankments, and dams. Furthermore, waterproofing membranes can be used to regulate water flow and enhance drainage in geotechnical projects. All in all, incorporating a waterproofing membrane into geotechnical applications can significantly enhance the longevity and performance of structures while effectively safeguarding them against water-related issues.

- Q: Roof SBS waterproofing membrane additional layer needs to be wide

- Roof SBS waterproofing membrane additional layer width of 15-20cm, angle attached layer 25cm on each side. Waterproof membrane is mainly used for building walls, roofs, as well as tunnels, highways, landfills, etc., to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials, as the basis for engineering And no leakage between the building connection, the entire project is the first waterproof barrier, the entire project plays a vital role. The main products are asphalt waterproofing membrane and polymer waterproofing membrane.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels or flooding?

- The utilization of a waterproofing membrane is viable for areas with elevated groundwater levels or occurrences of flooding. These membranes are specifically designed to create a barrier against water infiltration, effectively safeguarding structures from water-related harm. Commonly composed of materials like bitumen, rubber, or synthetic polymers, these impermeable membranes are applied to foundations, basements, roofs, and walls to impede water penetration. In regions where groundwater levels are elevated or frequent flooding is experienced, the use of a waterproofing membrane becomes even more essential. Functioning as a protective layer, this membrane prevents water from permeating the structure and causing potential damage. It guarantees that the building's interior remains dry and devoid of water-related issues such as mold, mildew, and structural deterioration. However, it is crucial to consider the specific circumstances of the site, including the level of groundwater or severity of flooding. In extreme cases characterized by high water pressure or prolonged flooding, additional waterproofing measures may be required. These measures could involve the installation of a drainage system or the utilization of thicker and more durable membranes. To ensure the suitable membrane system is selected and installed correctly for the unique conditions of the site, it is advisable to consult with a professional waterproofing contractor or engineer.

Send your message to us

SBS Elastomer Modified-bitumen Waterproof Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords