Plastic extruded board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Extruded board is made from polystyrene resin and small amount of additives through heating and extruding system. It is a rigid foam with honeycomb structure. Owing to its 100% closed cell structure, it is highly moisture resistant and waterproof.

xps extruded polystyrene insulation foam board is widely used in wall insulation, inverted roof insulation, construction of concrete roof and structure of roof, flooring insulation, cold room construction, ground frost control under express highway, low temperature storage facilities, parking platform, airport runway, as core material of sandwich panels and other areas of moisture-proof inexpensive decoration industry material.

Main Characteristics

1.High Compressive Strength

2.Water-resistant

3.Excellent Thermal Insulation

4.Dimensional Stable

5.Light Weight

6.Resistant to deformation

7.Recyclable

8.Long Service Life

9.Anti-microbial Corrosion, Anti-chemical corrosion, Anti-aging

10.Green environmental protection, energy-saving, non-toxicity

- Q: Will the experts: acetic acid plate and the difference between acrylic, resin sheet

- Organic chemical chemical industry is so complicated, only conventional products conventional method, that is, specify the specific conditions. And that are colorless and transparent products it, designated conventional cellulose acetate plate, conventional acrylic plate, conventional thermosetting resin board. Among the three, you can see the degree of colorless translucent to the highest acrylic, followed by resin, acetic acid again. You can see heat conditions, heating to one hundred and fifty degrees above, acrylic will soften the flow, the resin will be soft but not flow, and then raise the temperature, acetic acid will melt. Look at the situation of specific solvents, dip chloroform (chloroform) wipe the surface, acrylic solution, slightly soluble acetic acid, resin unchanged. Of course, for the specific different varieties, the situation is very different

- Q: Do you know the top of the wardrobe?

- The top solid wardrobe is made of high quality plate, special process, moisture resistance, formaldehyde emission meet the E1, E0 environmental standards, with anti-deformation, anti-mildew pest control, anti-acid, anti-scratch, recyclable The use of double-track single pull pulley, the last round of the United States DuPont pu materials, the next round of modified pps material, with wear-resistant, muffler, bearing the strong and so on. With the top of a special top and bottom seal, completely put an end to dust. The top of the wardrobe pulley is the international top of the sliding system, tight seal.

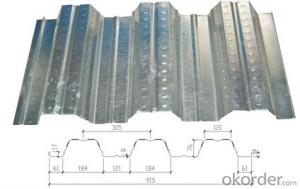

- Q: What is the difference between steel sheet and coil?

- The plate is the rationale for the price of the coil

- Q: Willow eucalyptus wood and pine which is good

- Many businessmen will use cheap wood eucalyptus, Malacca (another produced from Southeast Asia fast-growing cheap wood) core wood blockboard beautification into a "solid wood ecological board", attempt and solid wood detached, confuse, mislead consumers, but its essence Is still the use of cheap wood man-made sheet. The price is there. Pine, especially New Zealand pine widely used in the production of a variety of pine wood furniture, there are many specialized in the production of pine furniture brand, is also widely used in children's furniture and other fields. In addition, we must use a lot of glue and increase the risk of formaldehyde release. The plate will also increase the release of formaldehyde during the cutting process, and the same conditions do not have these problems. Of course, the use of blockboard can save a lot of cost, so for decoration, props production, especially public commercial space project is still very meaningful. So in general, a kind of wood is not dare to show his face, a large square is made of solid wood furniture wood. Combined with the actual value of the two woods in reality, and their application effects. Pine should be excellent and willow eucalyptus wood, Malacca.

- Q: What about the quality of the new millennium?

- This time you count the people, and my house when the house I studied the whole plate over time, the new millennium plate in general is a large manufacturers of products, in the high-end look, there is also a king coconut brand (first-line brand ), The new millennium is an economic series, the price is much cheaper than the bunny Moganshan millennium boat, the quality of these brands is almost the same, even better, because after all, the product is their own manufacturers, unlike those big brands, some products Not their own production, to go to the small factory to find almost OEM, environmental protection can not guarantee ,,, the new millennium home with a very appropriate, and now have E0 and E1 level, environmental protection coefficient is fully standard, miscellaneous brands and small factories of the most Do not use, even if the quality can be, but the environmental protection factor is certainly not up to the standard.

- Q: Fuqing plate quality how

- Fuqing plate quality is still very good, listen to the sale of Fuqing plate market, said: "Fuqing" brand is China's first registered trademark in Japan plate enterprises, Fuqing exports of Japanese sheet metal and similar products accounted for the country First, "Fuqing sheet" comprehensive through the ISO9001 international quality management system certification, the Chinese environmental labeling product certification, FSC forest certification, Japan's highest level of quality management system JAS certification, the product has reached Japan F ★ ★ ★ ★ level, the European E0 Environmental standards.

- Q: I only know plywood.MDF is a kind of plywood? Is MDF different from another board of plywood or just a piece of wood?

- MDF is medium density fibreboard, not plywood. Is another kind of sheet.

- Q: Is the quality of the letter sheet?

- Did not hear this brand, only know the top ten brands of plates in the bunny, Moganshan, Yu Fu Lin, the Millennium boat, the king coconut, their product quality certainly no problem!

- Q: What are the classification of timber for construction?

- uilding timber is divided into: logs, square materials, sheet, glue material. Good understanding of logs. Square wood is machined into rectangular or square, and the aspect ratio is less than 3. Thickness ratio greater than or equal to 3 for the plate. Plywood is a man-made material, is the use of various materials using the corresponding production process manufacturing. Logs, square wood is mainly used for columns, beams, roof trusses and so on. Plate, plastic material used for wall, ceiling and other decorative parts.

- Q: What are the harmful substances that man-made panels will release?

- Or the purchase of furniture used in the high-density fiberboard. These man-made sheet is the culprit leading to excessive indoor gas pollution. According to expert panel experts, the market of man-made sheet, the general use of urea-formaldehyde resin, in the use of the environment will release formaldehyde. And some poor quality, cheap big core board and other man-made sheet there is unreasonable use of plastic, so that the use of the release of a large number of formaldehyde, polluting the environment. ■ new house decoration must pay attention to the choice of decoration materials, try to use non-toxic and less toxic materials; preferably with green home improvement experience in the home improvement company construction, delivery requirements to provide indoor air quality testing report. ■ When buying furniture, pay attention to the formaldehyde and benzene release of furniture, the new furniture is best ventilation for some time, so that furniture in the release of harmful gases as soon as possible. ■ wood-based panel made of wardrobe must pay attention to, try not to underwear, pajamas on the inside. ■ fabric sofa should not only pay attention to the fabric, but also pay attention to the filler and the adhesive there is no pollutants. Can be used to reduce the indoor toxic gas effective air purification device, furniture to take some effective purification measures and materials, such as adsorption wardrobe in the adsorption of formaldehyde and so on.

Send your message to us

Plastic extruded board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords