Carbon Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding End Caps

Features standards and products of our Butt-Welding End Caps:

Features of Butt-Welding End Caps:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding End Caps:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding End Caps:

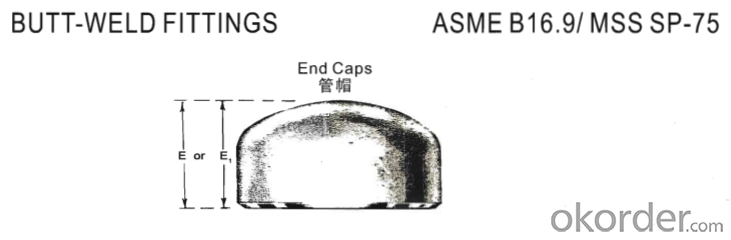

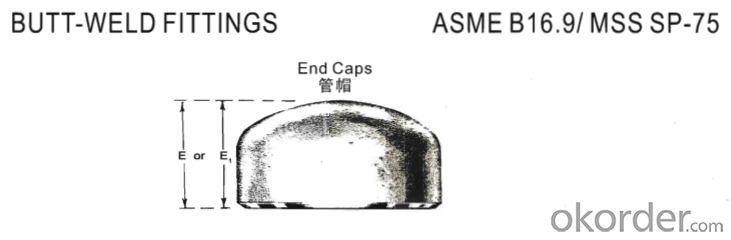

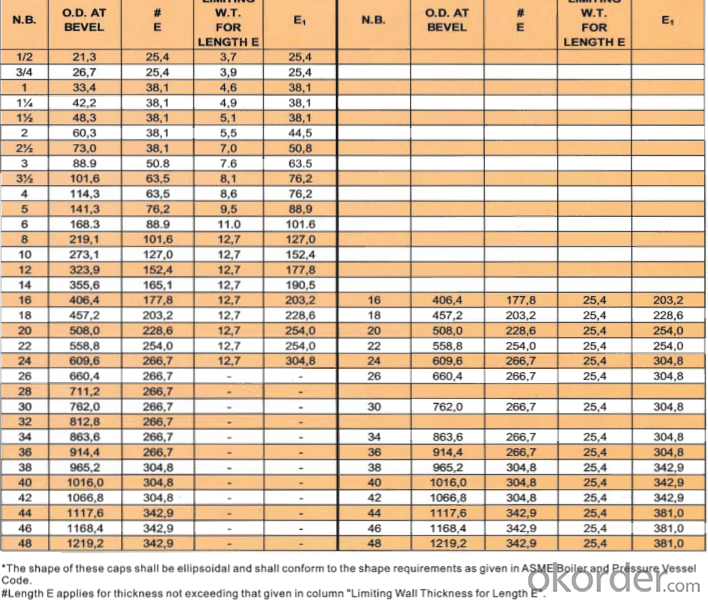

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding End Caps:

Packing of Butt-Welding End Caps:

FAQ of Butt-Welding End Caps:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:Is it just so they re more noticeable or is there another reason?

- put some chese on it

- Q:I had a stack able washer and dryer and the dryer broke, so we never got another one. I have a standard washing machine and we hang out clothes to dry (we only have 210/220 plugs and can't get a dryer). I use Gain or Wisk detergent and my clothes rarely smell good. Should I buy a smell enhancer for laundry?

- As mentioned in other answers, 'Program Files', should NOT be used to save user files, however if you do need to save it in this location, you would need to Elevate UAC. You can do this: Let's say you want to save a word file to that directory, 1. Right click on MS Word's icon, and select 'Run as administrator' 2. Open/Create/Modify the file you want, now you can save it anywhere, since Word is running with an elevated privilege.

- Q:i know they think space is like a flexible-fabric that u can bend, and that gravity is like mass weighing down on space, pulling it downward and drawing other objects closer to it, but how does that make time only as relative to the mass of the gravity that weighs down spaceplease help

- Go in opposite directions.

- Q:Have you ever had a day where you view everyone else as dogs and you are the fire hydrant?

- Surge protectors help protect electrical equipment.

- Q:I was shooting a film at school using a fog machine and the fire alarm went off. However I am not positive it was the fog machine that set it off because 2 janitors ran by the room and I heard that they thought it was smoke and pulled the alarm, I am not sure though. Anyways we told a teach after all 3 thousand students where out of the school that it was probably the fog machine. Anyways we talked to the principal about it and he said he would let us off because it was an accident and a teacher knew about it plus we told a teacher it was us. Well he said that the fire department might fine the school for the alarm going off without an actually emergency and the school would make my group pay it. The principle said once a student pulled the fire alarm before as a prank and had to pay $1000 for the fire department coming. Is this legal and would I have to pay this? Any input would be helpful

- it has not been used in a while! I lived in apartmest most of my life so lets just say 25 years! and EVERY year we got that same burnt smell! When the fumes that light the furnace haven't been used in over a month they have to burn off all that dust and other particals that are on the furnace the smell should go away after 3 days! we got in the habit of turning our heat on in fall with the windows open just so we wouldn't have to smell that and freak out! so don't feel bad even after knowing this happends we still check EVERYTHING lost my home in a fire i would reather be safe then sorry!

- Q:thereis a 1 foot long piece that comes out from a fitting in the masonry - I don't feel good abouit lighting a wood fire in teh fireplace with the black pipe in there. the end of the blackp pipe is open. Very rusty, can't get the elbow fittings loose. Thinking about cutting off the pipe, but howw to seal it against fireplace heat? Really want to use the fireplace for wood.

- cellotape. wrap it round your fingers then use the sticky side to pick up the stuff.

- Q:Why do u feel that wayhere is it: body-focused:

- massachusetts motorcycle permit test

- Q:There is so much argument online, much of it around 2009. What is the current law? Can I see a link to something official? Thank you in advance.

- If the temperature gets below freezing in your area, you don't want the copper pipe exposed. Fine to use sharkbite fittings, but need a frost proof hose bib in order for it to not freeze in winter.

- Q:What are the differences between hydraulic couplings and fittings and elbows?

- The elbow is the pipe that changes the direction of the pipe. According to the angle, there are 45 degrees and 90 degrees, 180 degrees, three most commonly used, in addition, according to the project needs, including 60 degrees and other non normal angle elbow. Elbow materials are cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, nonferrous metals and plastics. The way to connect with the pipe is: direct welding (the most commonly used way), flange connection, hot melt connection, electric melting connection, threaded connection and socket connection. According to the production process can be divided into: welding elbow, stamping elbow, push elbow, casting elbow, butt welding elbow. Other name: 90 degree elbow, right angle bend, love bend and so on.

- Q:PT1/4 large diameter pipe joint? No figure urgently

- The basic size of large diameter pitch thread code P per inch TPI in diameter of external thread tooth type D3 path height H1 bottom hole sizeG, 1/4, 1/4, 13.157, 1.33719, 12.301, 11.445, 0.856, 11.6

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords