Q41F-10C series lining fluorine ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

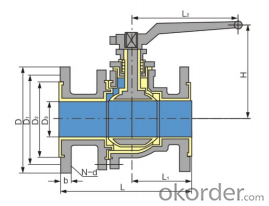

1. Q41F-10C series lining fluorine ball valve descriptions

Q41F-10C series lining fluorine ball valve is a professional design for the opening and closing of all kinds of strong corrosive medium, the body USES the carbon steel precision casting, lined with fluorine plastic ball valve and flow components are using steel skeleton outsourcing fluorine plastic.

Widely used in petroleum, chemical, acid alkali, pesticides, dyes, waste-water treatment, electroplating, electronics and other industries.

2. Application environment

Applicable temperature-20℃~120℃

Nominal diameter:(DN)20-250mm

Nominal pressure:(PN)1.0MPa

3. Model sense

EX : Q41F-10-C-65

-Q: Type code:ballvalve

-4: Code for connection type: Flange

-1 : Code for connection type: Floating direct flow type

-F: Parts which is in contact with liquid flow is made with fluorine plastic

-10: Nominal Pressure 1.0MPa

-C: Material of valve body is carbon steel with melt mold

-65: Nominal Diameter is 65mm

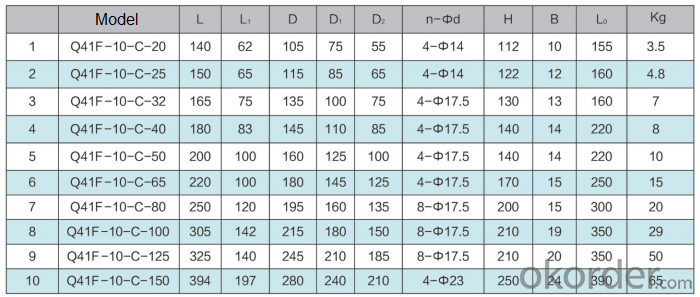

4. Model and parameter technical

5. Products features

-The fluorine lined ball valve with FEP lining layer has extremely high chemical stability and can be applied to any strong corrosion property except "molten alkali metal and element fluorine".

- Fluorine lined ball valve adopts the structure of full diameter and floating ball. The valve can be closed without leakage within the whole pressure range, which is more convenient for the ball cleaning and pipeline maintenance of the pipeline system.

- Ball parts and valve stem casting (forging) are integrated, eliminating the possibility of the valve stem bursting out of the pressure part due to pressure change, and fundamentally ensuring the safety in engineering.

- Fluorine lined ball valve structure is compact and reasonable, the body cavity space is the smallest, reduce the medium retention, in addition, special molding process, make the sealing surface density is good, combined with herringbone PTFE packing combination, make the valve to achieve zero leakage.

-Two-piece, three-piece structure can adapt to a variety of different requirements of the pipeline system and working conditions, including three-piece ball valve allows the main valve body and two sides of the body separation, ensure rapid online replacement, maintenance.

- Q: Hi. I am planning to install new kitchen faucet and noticed that there are two shut off valves under the sink. One of them is badly rusted and needs to be replaced. I noticed that it is connected to three pipes (one of which is kitchen faucet). The other is clearly water coming in. What is the third one connected to wall? Also how should I go about replacing this? Anything that I should be careful of?

- it looks like a 1/2 inch galvanized pipe out of the wall, and the valve is screwed on to it. kinda hard to see the back side of the valve and pipe. it could be a 1/2 inch copper pipe and the valve could be a compression type. anyway, you will have to cut the water off unless this is the hot line in and if so you can cut the water off at the water heater. its probably a cold line in and obviously you cant take the valve off without cutting off the main supply line some where. take off the two small lines and don't move them around to much, they are compression fittings so just reattach them to the new valve. then unscrew the valve, you may have to hold the incoming pipe but just try the valve first. take the valve to a plumbing supply, Lowe's, or home depot and get one just like it. if one place doesn't have it go to another and find the same valve. if it screws on get a small tube of pipe dope to coat the threads. if you anticipate problems get a 1/2 inch galvanized cap [if that is the pipe you have coming out of the wall] so you can plug the pipe and cut the water back on temporally. this is general info so you will have to deal with your special situation. good luck.

- Q: I am trying to repalce the water turnoof valve under my sink but the valve just keeps turning and no progress is made to get it off so I can put on a new one. I am turning it clockwise but it just keeps turning. Can someone please tell me how to get this off? I do not want to have to call a plumber for something that I might be able to fix myself.Thanks.Sandy

- basically component to the diverter valve is broken, besides the undeniable fact that, it extremely is terrific to replace to total diverter stem. If their are 3 handles, you are able to do away with the middle one devoid of turning the water off. Then convey total stem with you to the ironmongery shop. There are quite some video clips on youtube and different ironmongery shop factors of interest in case you like help. good success.

- Q: Com wires attached to com and all individual valve wires are attached. The valves work manually( turn on by hand), I open the valve to allow the box to take over and the sprinklers run. Is this just residual water in the lines??

- I would test the leads inside the control box first... You will have to run the controls manually to troubleshoot the problem. Get a voltage meter to test for the 24 volts at the transformer connections inside the box... If you do not have the 24 volts then the problem will be the transformer. If you have the correct voltage from the transformer then you can test each of the station terminals to common. Test through each station to see if you have 24 volts at each station terminal, but you may have to remove the wires off to test. If you do not have power coming from each station… then the problem will be the rain bird control. The next step would be testing the wires… If you reconnect the wires… test just prior at each valve location to see if you have the 24 volts between the common and each station wire… if you can prove out that there is 24 volts at this location then you’re down to the final testing. Reconnect the valves – one side to the common and the other to each station wire… Getting the power (24v) to the valve should have cleared your problem. Good Luck… Running the valves manually will not affect the operation of the rainbird control... but with my rainbird valves.. you can shut off the valves completely and disable the electrical controls of the valve... make sure that you have not closed the valve off manually preventing the electrical side... a problem with rainbird controls. This does not have anything to do with residual water in the lines... I would test this side first before you get into the electrical side... could save you a lot of time.

- Q: Hi,I have a 2002 Honda Accord with 115k miles which recently gave a ECL. The Honda dealer identified this a P1457 and says that the EVAP bypass solenoid valve needs to be replaced1) is this referring to this valve?

- DTC okorder Otherwise: Don't forget to close the question. Thank you.

- Q: My vehicle has 160,000 miles and has burned 2 quarts of oil at 3000 miles. Someone told me to change the PCV valve because sometimes a bad PCV valve can cause oil consumption. I appreciate your assistance.

- the pcv valve is on the valve cover just pull it up and it comes right out, if you see a hose going from the valve cover to the intake manifold thats the one . You also might want to make sure you are using the right oil for your truck for that truck ford recommends to use 5w-30 oil. Perform a cylinder compression test or perform a cylinder leak detection test with Engine Cylinder Leak Detection/Air Pressurization Kit. This can help determine the source of oil consumption such as valves, piston rings or other areas. Worn or damaged internal engine components can cause excessive oil consumption. Small deposits of oil on the tips of spark plugs can be a clue to internal oil consumption. Other problems might be: Sticking valves, worn valve guides, poor valve seating, burned or warped valves, worn rings. Perform a intake manifold vaccum test, that will help determine the problem.

- Q: Is there a product that can fit over a foot valve to give it further protection in muddy water? I am looking for something for forest firefighting in mind. Something like a screen box something else that can give it further protection. It would be nice if it was small, and compact. Pictures would definitely be an asset. Thanks to everyone that answers. Greatly appreciated.

- most foot valves i have bought come with a strainer attached perhaps you should look for that type. if your valve has a strainer you may consider making a further coarse strainer out of a ball of chicken wire and place this over the foot valve assembly(thats what i do for the cold water supply to my house) don't compress the chicken wire very small as it will block up i tie the wire filter on with galvanized wire then i can easily replace it if necessary ps i tried stainless steel pot scourers but they were to fine and blocked easily

- Q: I'm thinking about getting a Cold air intake along with a Bypass Valve to prevent Water Indigestion on my Toyota Corolla 07. I was wondering if Bypass Valves actually work and can someone explain to me the physics around it???( How bypass valves work)

- This Site Might Help You. RE: Cold Air intake + Bypass Valve. ? I'm thinking about getting a Cold air intake along with a Bypass Valve to prevent Water Indigestion on my Toyota Corolla 07. I was wondering if Bypass Valves actually work and can someone explain to me the physics around it??( How bypass valves work)

- Q: I have a T4-T10 and L5-S1 spinal injury and I recently found out that my tricuspid and my mitral valves leak. I have never had heart problems before I got the spinal injury. Do you think the valve leaks could have been from the trauma when I received the spinal injury?

- Maybe but usually MVP doesnt give people much problems and if it does usually sudden

- Q: My friend is having 3 valves in her heart replaced with pig valves. Her dr said that putting in human valves raises the risk of her body rejecting them but wouldnt your body also reject a part form different species? And if they only last a few years why use them at all? shes all freaked out about the surgery so I dont want to ask her too many questions

- This Site Might Help You. RE: why do they use pigs heart valves for humans? My friend is having 3 valves in her heart replaced with pig valves. Her dr said that putting in human valves raises the risk of her body rejecting them but wouldnt your body also reject a part form different species? And if they only last a few years why use them at all? shes all freaked out...

- Q: I was diagnosed with Mitral Valve Prolapse. Does anyone else have this? Does this cause panic attacks? I have heard that. What other problems does it cause?

- What is mitral valve prolapse? How does a patient with MVP feel? How is mitral valve prolapse diagnosed and evaluated? What is the treatment for MVP? Mitral Valve Prolapse At A Glance What is mitral valve prolapse? Mitral valve prolapse (also known as click murmur syndrome and Barlow's syndrome) is the most common heart valve abnormality, affecting five to ten percent of the world population. A normal mitral valve consists of two thin leaflets, located between the left atrium and the left ventricle of the heart. Mitral valve leaflets, shaped like parachutes, are attached to the inner wall of the left ventricle by a series of strings called chordae. When the ventricles contract, the mitral valve leaflets close snugly, preventing backflow of blood from the left ventricle into the left atrium. When the ventricles relax, the valves open to allow oxygenated blood from the lungs to fill the left ventricle. In patients with mitral valve prolapse, the mitral apparatus (valve leaflets and chordae) becomes affected by a process called myxomatous degeneration. In myxomatous degeneration, the structural protein, collagen, forms abnormally and causes thickening, enlargement and redundancy of the leaflets and chordae. When the ventricles contract, the redundant leaflets prolapse (flop backwards) into the left atrium, sometimes allowing leakage of blood through the valve opening (mitral regurgitation). When severe, mitral regurgitation can lead to heart failure and abnormal heart rhythms. Most patients are totally unaware of the prolapsing of the mitral valve. Others may experience a number of symptoms discussed below. The mitral valve prolapse (MVP) syndrome has a strong hereditary tendency, although the exact cause is unknown. Affected family members are often tall, thin, with long arms and fingers, and straight backs. It is seen most commonly in women from 20 to 40 years old, but also occurs in men.

Send your message to us

Q41F-10C series lining fluorine ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords