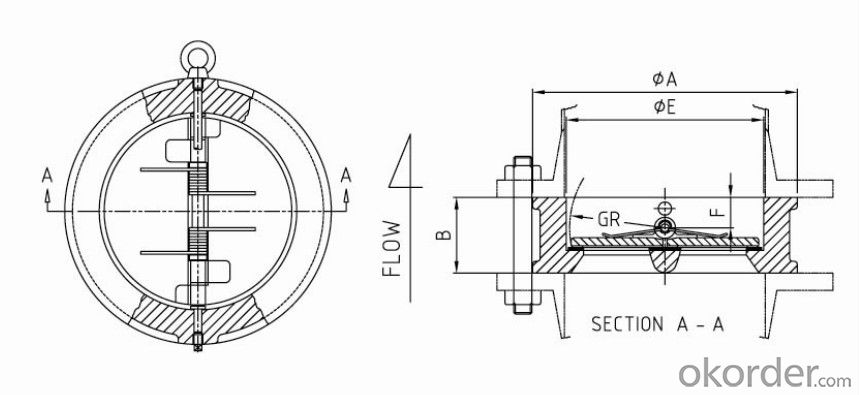

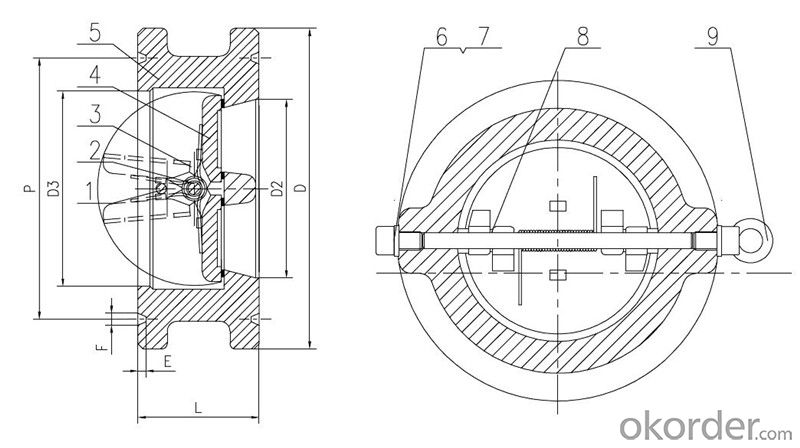

Swing Check Valve Wafer Type Double PN 10 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Hi. I replaced my PCV valve but the hose it connects to is cracked at the end. It's still loose and I can pull it off with my hand. It is very hard to get it to stay connected. So my question is that while I am driving, what would happen if the PCV valve accidently disconnects from the hose? Would I still be able to get to a service center?

- Depends on the vehicle, most cars may run rough, sluggish, some wont even run, every car is different on how much actual vacuum is running through the pcv valve that will determine if its drivable. Run it for a minute..drive it around the block make sure it wont die...then take to the shop.

- Q: I have a mountain bike that my brothers left me. the tire in the front is a normal s valve, the one in the back is a presta valve. now this was ok because it was fully pumped up, but then it popped on the road, so i got a new tire ad put it on and was all ready to pump it up but when i tried to pump it no air would go in. so i looked at it a while and i figured out the top unscrews, so i unscrewed it and put the pump back on and started pumping, but after a while i figured out that no air was going in the tire and now i'm very confused.

- A presta valve can be a little finicky. If you don't push the pump nozzle down far enough, it won't let the air into the tube. Unscrew the valve, line up the pump head with the valve stem, push down firmly while twisting back and forth. Try pumping; if it builds up pressure, just push it down until it releases into the tire. Don't forget to pull up the lever on the pump nozzle.

- Q: 2003 Ford Focus SE2.0L SPI EngineAutomatic Transmission 145KPerfectly maintained since new!One of the pistons had snapped, yes the actual piston, it didn't mess up the walls, but I am hearing a LOT about these dropping valve seatsI intended to do an entire rebuild with a kit, but did it break BECAUSE of a droppedvalve seat?I don't know because I don't know what that isHelp is appreciated

- highly unlikely , depends how the piston is broken often when revving too high the piston top will separate at a ring groove nothing to do with valve seats

- Q: I really like the sound that a blow-off valve makes when they are in audi tts. So I was wondering if I got one for my '02 225hp Audi tt if it would damage the engine in any way. I have read that diverter valves are better, but I want the sound of the blow-off valve. Also any recommendations on blow-off/diverter valves would be great.

- Blow off valves are nice, but they aren't terribly good for your car. The main problem is that when the turbo isn't running, that open valve will suck unfiltered air into the engine and can seriously damage it. Blow offs are also pretty inefficient as you lose a good portion of the air in your turbo system. The best thing you can do is just get a good Forge diverter valve. Well made, looks nice, and will add a pretty decent amount of performance.

- Q: It's just a small 1 cylinder 1000 watt generator but thanks to contributors here, I verified the exhaust valve is pitted after I cleaned it all up with oven cleaner a toothbrush. My question is can I just replace the valve itself or do I need an entire new head? The seats still feel smooth.

- You can replace just the valve. You should lap the valve to the seat though. That requires a lapping compound and some way to spin the valve. This is done before installing the spring. Lapping ensures that the valve is seated and won't leak. In the old days I have used comet cleanser and a small suction cup chucked in my drill. Worked fine. I know that is not the correct method but it worked and my mower ran for several years after that. Auto zone may have a valve lapping tool that they will loan out and you can buy some real lapping compound to do a better job. I always enjoyed getting the job done with what I had on hand. Good luck.

- Q: how do u remove a valve seat from a head, and install the new one?

- What engine? Not all heads have valve seats that are pressed in. Some (many later model cars) have the seats ground right into the head and are not removable.

- Q: I did a compression test, and I have a broken valve. everything else is in perfect condition besides this valve and I have carbon getting built up in one of my pistons. Can I run the car like this? What cause this from happening what was the cause age?1999 Ford Explorer 4.0 OHV with 146k,miles

- in case you have a broken valve, the broken element will probably destroy the cylinder and piston in case you run it that way. ought to easily be a flaw in the unique valve or another ingredient, no longer person-friendly to appreciate.

- Q: Are all the valve created games tied together somehow? Except for TF2 like in portal 2 glados says she might start a hobby of reanimating the dead so is that left 4 dead?

- The only Valve games that exist within the same universe are Half Life and the Portal series. Aside from referencing each other, Left 4 Dead, Counter Strike, and Team Fortress 2 and all other valve games exist in their own respected universes. Left 4 Dead cant exist within the same universe as Portal since l4d takes place in the year 2008. And as Portal and Half Life share the same timeline, the combine would have already taken over the planet at this point and in left 4 dead you don't see any of this. Also in Half life 1, the portal that allowed the combine to enter earth in the first place took place in 2000 in the game's story, again you dont see any of this in l4d. There are some other stuff in there but I don't feel like getting more into it. Oh yeah one more thing, In L4D2, Louis mentions that he feels like Gordon Freeman when he is on the minigun, the protagonist from Half Life. So according to L4D universe, half life is a video game just like in the real world so that would mean that Portal is too because both those series are tied in.

- Q: My son was born with bicuspid aortic valve which has developed a leak. He is now on enalipril 2x per day to decrease the afterflow and buy some time before he has to have surgery, but the doctor has discussed our options and we basically have to choose when it comes down to it, whether we go with a valve repair, or valve replacement and if we do replacement we can do mechanical or donated valve or The Ross procedure. And he will probably be under 5 yrs old when this needs done, (he's 2 now) so I would like to keep him off of coumadin (blood thinner) so he can play sports in school if he would like. But I also want to do what is the best for him long term. Any advice would be helpful. thanks

- OK I HAVE A 4 YEAR OLD THAT HAS AEROTIC STENOSIS WHICH MEANS THAT AT THE AGE OF TEN HE WILL HAVE TO HAVE A VALVE TRANSPLANT. THE OPTIONS RIGHT NOW ARE A PIG VALVE, WHICH LASTS AS LONG AS A PIG WOULD LIVE, OR A SYNTHETIC VALVE WHICH CAN CAUSE CLOTTING. BUT I WATCHED A DOCUTMENTARY ON A HEALTH SHOW ABOUT A MONTH AGO, AND DOCTORS HAVE INVENTED A WAY TO GROW A HEART VALVE USING CELLS FROM YOUR KIDS HEART. NOW IT WONT BE APPROVED FOR ANOTHER 10 YEARS BUT I JUST THOUGHT I WOULD LET YOU KNOW THAT IT HAS ALLREADY BEEN TESTED AND WAS SUCESSFULL, IF I HEAR ANYTHING ELSE I WILL TRY TO FIND YOUR EMAIL AND LET YOU KNOW. IM PLANNING ON DOING THE PIG VALVE UNTILL THE MEDICAL BOARD APPROVES THE REAL VALVES, THAN I WILL HAVE THAT DONE TO MY SON, SO I WILL NEVER HAVE TO WORRY ABOUT IT AGAIN. GOOD LUCK, I KINDA KNOW WHAT YOUR GOING THROUGH. keep in touch with me, and let me know.

- Q: I am trying to remove my supply valve behind my toilet to replace but the valve wont come off. I am using a cresent wrench to turn it and it turns but does not unscrew. How can I remove this piece?

- Stop! I'm assuming you've got threaded pipe and not soldered joints here, You need a wrench on the pipe as well. Allowing that pipe to turn can loosen the connection in the wall an cause a leak if you haven't already done so.

Send your message to us

Swing Check Valve Wafer Type Double PN 10 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords