Swing Check Valve Wafer Type Double PN 1 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

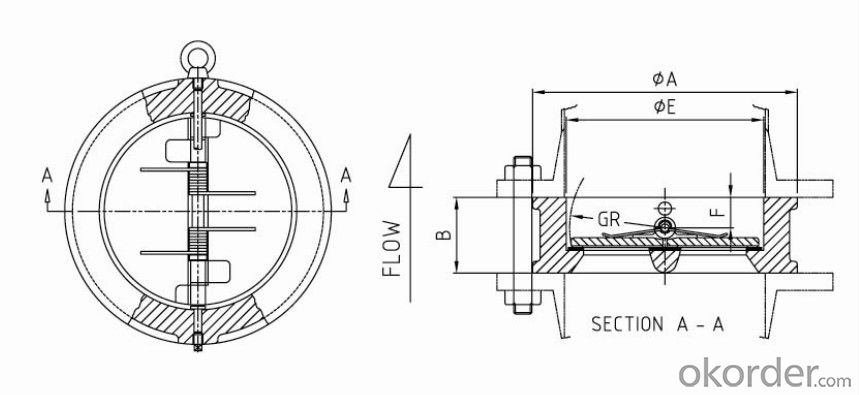

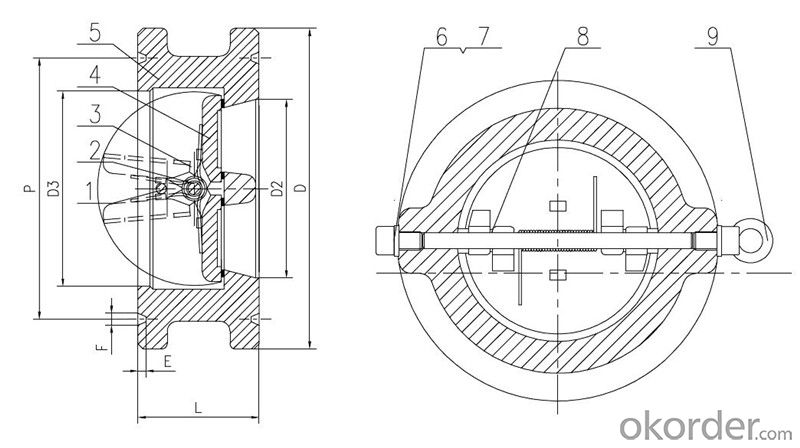

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: My AC leaks and mechanic says it is shrader valve. Is it expensive?

- It's cheap - even free if he's going to invoice you for re-charging the system. If he normally does A/C service he should have an extra one on hand. To replace it legally you would need a recovery machine to evacuate the system, replace the valve and then recharge the system. Probably $100. worth of service. To do it backyard style you'd put some gloves and goggles on, remove the leaky one and jamb the new one in while refrigerant is spewing out and then top up the system. Backyard style is almost impossible on a warm day because the refrigerant will be under high pressure, it would definitely make a good youtube video. If you did it on a very, very cold day (it stays in liquid form -15F), it would be easy because the refrigerant would be at a very low pressure.

- Q: Ok, I recent rebuilt a set of vortec heads, but the valves I got are a bit longer than stock, I believe .1 competition products pn I2552P. I also installed howards cam 98214 springs with 10° locks and retainers, the locks are +.035. I was just wondering if I would have enough spring pressure.

- You need to measure your installed height. No guessing here at all. Measure to be sure. If you don't have a valve spring micometer, you can use a std dail caliper's outside jaws. Remove spring, put retainer on, put 2 locks in, and pull up on retainer till it seats in lock groove. Now measure from spring seat on heads to bottom of retainer.. If you have to then you can measure to top of retainer and then measure thickness of retainer and take that off of your total. You have to know the installed height to figure spring pressure change. The 98214 springs has a rate of 411.. That 411 # per 1 inch and rated installed height is 1.700 So you take the amount of change from the 1.700 and X it by the rate of 411 and that's your total pressure change.. Then take or add that to your rated pressure (which is 115 #) and that gives you your new spring pressure So lets just say installed height is now 1.750 So .050 x 411 = 20.55 #, 115 - 20.55 = 94.45 # total seat pressure Now you need to list the cam your running, diff lift needs diff amount of spring pressure ***EDIT*** Thats a .465 lift cam. If your not winging RPMs past 5,000 then you can get away with a 80 # seat pressure spring, 6K rpm you would need about 5-8 # more seat pressure

- Q: I am looking at getting a baritone horn of my own, but am not sure what compensating versus non-compensating valves are?

- It okorder /

- Q: Specify eight technical requirements that you would consider important, when deciding upon a particular control valve?

- 1] I assume that by control valve you mean a variable orifice valve, not an on/off valve. 2] An answerer to your other question listed Metallurgy, temperature, pressure and shutoff requirement To which I note that if you need a tight shutoff you should not trust a control valve to do that, but should add an on/off valve in series. Also, metallurgy covers corrosion requirements but not obviously so 3] To which I add: flow rate [or Cv] and pressure drop fail open or fail closed response time signal input [3-15 psi, 4-20 mA, 1-5V, etc] connections [ie, fitting type] packed vs sealed might need to look at hard seat materials and/or replaceable seats, to control erosion reliability, ease of maintenance, availability of spares, timing on that vendor permanence [ie, are they entering bankruptcy ?] Cost

- Q: What is the purpose of the LNG Vs Propane Valve that has to be installed on Gas Stoves/Ovens before use ? How can I set it myself for Propane ? What negligible effects would I experience if I hook a stove up to Propane while the valve is set-up for LNG ?Thank You !

- The difference is the size of the orifice. I've never changed it myself but I don't think it could be too difficult, however I've always had a professional do it for me. The reason for this is that propane and natural gas (methane) have very different Btu contents. Propane has a much higher Btu content and the orifice for propane is smaller. There is also a small difference in pressures of the supplied gas as pointed out below, but it is small. If you hook up propane while having the natural gas orfice installed, you may experience problems with incomplete combustion (soot) and the appliance getting hotter than design due to too many Btu's. LNG (Liquid Natural Gas) is a cryogenic form of methane. It is generally stored at -250 deg F. It is not used for domestic fuel.

- Q: I did a compression test, and I have a broken valve. everything else is in perfect condition besides this valve and I have carbon getting built up in one of my pistons. Can I run the car like this? What cause this from happening what was the cause age?1999 Ford Explorer 4.0 OHV with 146k,miles

- Let me guess, cylinder number 3? (passenger rear) Let me explain. In the last year, we've had three 4.0 Explorer's in our shop with a hung valve on #3. The last one we had in the shop, the valve broke without warning and broke the rod which cracked the block on the drivers side. They said it was running fine one second and made some noise and it started missing. It wasn't even knocking when it came in. Something about the #3 on those.

- Q: 1990 5.7l with a .470 lift cam , is there going to be a clearance issue between the valve guide and the valve. Is the rocker going to bottom out on the guides and bust my heads.. If so what should i do.

- Get yourself a degree wheel and check. A valve stem usually has about 1-1/2 thousandths of an inch of clearance between it and the guide to allow movement and lubrication. Your camshaft has no bearing on this clearance. If you want a wild guess as to whether or not you might get coil bind in the springs, rocker bind against the rocker stud or even valve spring retainer smashing into the top of the valve seal then my guess is not, not with just .470 lift. Probably would take more like .500 for any of that to happen.

- Q: My grandfather is going in for a valve replacement.. and I'm really worried about him.. I just want some information.. any good websites if you have them.. I looked on google.. But if you have any good ones that would be great..No horrible comments please..

- sorry okorder

- Q: The water shut off valve that is under my sink in the bathroom is leaking and I need to replace it. I am wondering if I need soder the new one or can I just put some thread tape around it.

- you solder it, because your pipes have to be copper, which never have threads, so the threads tape would be useless right? just ask a plumber to come over and do it and watch them, really good way to learn without paying a college degree.

- Q: Hey, ive got a scooby and have a baileys dump valve that is a loud deep wooooosh sorta sound. What dump valve does the more high pitch sound? also they dump valve with the higher pitch seems to need less presure ta dump, mine needs alot of pressure before it will dump loud?

- if i remember rite you can adjust the control settings for your dump valve so that it will dump at a lower pressure and a lower pressure dump should also give you the sound that you are looking for.

Send your message to us

Swing Check Valve Wafer Type Double PN 1 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords