Gate Valve for Water System of China High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 60000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

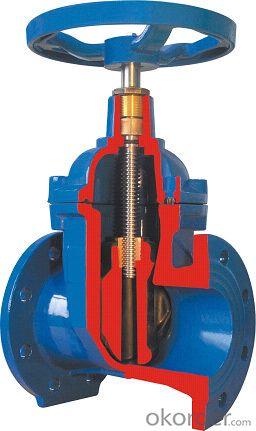

1. Structure of Gate Valve Description:

1. Selected materials, in line with domestic and international standards, high overall quality of the material.

2. In line with the requirements of domestic and foreign advanced standards, reliable sealing, excellent performance, attractive appearance.

3. Sealing pair advanced and reasonable, gate and seat sealing surface with different hardness Stellite (Stellite) cobalt-based alloy cladding made, reliable sealing, high hardness, wear resistance, high temperature, corrosion good anti-abrasion performance, long life.

4. The use of flexible wedge gate structure, medium and large caliber set thrust bearings, friction force is small, and with a striking manually open and close with ease.

2. Main Features of the Gate Valve:

stainless steel flanged gate valve Z45T-10 valve uses wedge-type elastic single gate structure, apply to the temperature less than or equal 135 degrees of water, steam, oil in pipeline and other media to open and close. Main features: body is made from precision casting, sleek style seat closed plate tightly ,reaching no leakage, no sediment, circulation, smooth, open and close flexibly.

1)Full port design

2)OS&Y Outside screw and yoke .

3)BB. Bolted Bonnet .

4)Flexible wedge, Fully guided

5)Choice of solid or split wedge .

6)Renewable seat rings

7)Forged T-head stem

8)Rising stem and non-rising handwheel

3. Images of the Gate Valve:

4. Specification of the Gate Valve:

1.Material:A105,A105N,F304,F304L,F316,F316L,LF2,F5,F11,F22,F347,F321,F51,Monel......

2.Size:≤3"

3.Pressure: Class150~2500

4.Connection Ends:

1)Socket Welded Dimension:ANSI B16.11,JB/T1751

2)Screw Ends Dimension:ANSI B1.20,JB/T7306

3)Butt Welded:ANSI B16.25

4)Flanged Ends:ANSI B16.5,JB79

5. Pressure grade: PN10, PN16

6. Coating:

a) Fusion-bonded epoxy 200-250 microns inside and out side

b) Coating as per customers' requirement

5.FAQ

1. Can I get free samples?

A: Yes,we can provide you the free sample, but you need to bear their own delivery costs.

2. Can I request to change the form of packaging and transportation?

A:Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3. Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4. Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear

their own the cost.

5. Can you produce the products according to my own drawings?

A:Yes,we can produce the products according to your drawings that will be most satisfy you.

- Q: Hi. I looked at instructional videos for installing shutoff valves and instead of simply unscrewing old valve, the plumber simply cut the copper pipe. Is this necessary? Why can't I simply unscrew old shutoff valves from copper pipe?

- Before you think about cutting the pipe. You should know there is water pressure behind it. You must first shut your water off at the meter. If you opt to take on this endeavor by yourself you have some easy options. There are four types of connections to my knowledge. Soldered is most common and very effective but takes know how. Then there is compression, threaded (which involves sweating a connection on the copper, and then some genius has came out with this new type of connector commonly refered to as shark bite or gator bite (those being the top two leading brands). With these connectors all you must do is put the little plastic insert in the pipe then push the connector on. Ta da! Then your done. I would even bet they make a push on connector with the shut off valve. So to recap. Shut off water, cut the copper and remove burs from pipe, take that piece to the hardware store so you know you have the correct size of pipe fitting. Go home and push it on and then turn your water back on and your done.

- Q: HAS ANYONE HAD VALVE REPLACEMENT (WITH PIG VALVE) OPEN HEART SURGURY. WHAT WAS THE RESULTS? HOW DO YOU FEEL NOW?

- Pig valves and Cow valves are the tried and tested valve replacements used for longtime. These work well and have minimum post-surgery problems.. Go ahead.. Al the best..

- Q: I have a 2000 Ford Explorer sport(2wd). I live in the Fort worth,Tx area. What would be a resonable price to have this valve changed out with a new one(valve labor)?

- Valve is about $100 at dealer, $40 at Autozone, give or take, and it should take about 30 minutes, so I would guess about $150 max. I have same problem with 2002, trouble is it's on the transmission, and not that easy for a DIY. As to changing it, mine has caused the check engine light to go on, but has in no way effected the car, so I haven't bothered to change it yet.

- Q: I wanna do it myself My dad knows how But i must buy the parts I have a rmz250 and i was wondering if u can jus buy valves and seals and jus put them in without grinding since the seals are new i heard u must gring the seals to get the valves to sit flush againt the metal serface but cant u jus buy new seals and retainers and put that in plus the valves and ur done?

- you *can* just put the valves seals in and run it but it is NOT recommended. If you want the best seal which will = the most power, the valve seats need to be cut. If your not running a titanium intake you could get away with just lapping the valves with course and then fine lapping compound. I know a lot of people who just lap them in, but the most professional way with the best results is to cut the seats.

- Q: If I buy one of those Presta valve adapters can I just screw it on and leave it on while I ride? Will I lose air pressure at to fast of a rate?

- If ya want to leave an adaptor on you could. I would close the valve though. That way you would have the adaptor always available. It only takes a few seconds to open the valve to fill the tire. Or, like most people, simply buy a punp that fits presta.

- Q: I was woundering if anyone had a repair manual for this valve on a 2004 Nissan Maxima. I just bought the car and Im getting the P1800 Code. Any help would be appreciated!

- 2004 Nissan Maxima Manual

- Q: I have a Chevy Silverado 2500 5.7L V8. I have been having problems with passing smog. First one failed because it needed a new cat. Replaced it and tested again. NOx emissions are off the chart (1450/1006 max of 992/59615/25mph). I replaced the EGR valve based on a suggestion. Quick test today said the NOx emissions are still way off. Suggested that I change the EGR solenoid valve and also pull the EGR valve and use a coat hanger to clean some of the carbon build up. I purchased a new solenoid today but looking at it I noticed something. Since there are what are appear to be two ports on one side of the solenoid, I must have replaced the vacuum hose onto the wrong one after replacing the EGR valve. How much would this make a difference on the test readings taken? Would it be beneficial to just replace the solenoid anyway or try to test again with the current one but connected properly?

- try changing the egr vac solenoid, and the O2 sensor. dad has a 1992, and i replaced the egr valve, the solenoid, all the vac lines, and the O2 sensor to get rid of a missfire, and help mpg. we dont do smog tests here, so it wasnt for a smog reason went from 12mpg to 15 mpg. your supposed to connect the egr to the normally closed port on the solenoid. should be the top port. there is supposed to be a bit of foam glued to the VENT port. check your check engine light codes, you can do it in 5 minutes by jumpering terminals A and B. read more about it online. code 32 is the EGR code, its the most common code on these old trucks

- Q: How does a thermal bypass valve work, specifically in a car.

- Water flowing into the valve is directed to two outlets. One outlet directs water back into the engine to recirculate and the other outlet directs water to a radiator where its cooled and the returned back to the engine. The amount of flow diverted to these outlets depends upon the position of the valve disk. In a car engine the water is constantly recirculating through the ports of the engine and the thermostat is located in one of these passage ways. The thermostat and its valve creates a third port or second outlet that allows water to flow to a radiator. When the valve is closed the water bypasses the radiator and recirculates hrough the engine. How much flow is diverted to the radiator is done by a temperature sensitive component that causes mechanical movement of the valve position based on the water temoerature flowing through the valve. the hotter the water the more flow that is diverted to the radiator to cool. The colder the water less flow is sent to the radiator and more flow is recirculated back to the engine bypassing the radiator. The mechnical sense element of what is commonly called a thermostat is called a pill. It consists of a sealed unit which for lack of a better description acts like a piston inside a cylinder and the cylinder is filled with wax. This piston is free to move back and forth but is limited in its movement because the wax is incompressible and a spring is pushing the piston back agains the wax. Now as the temperature warms up the wax melts and the liquid wax expands as it heats up. As the wax expands the piston is moved agains the spring and the shaft attached to the piston is used to move a disk away from the seat of the valve and allows more water to flow to the radiator.

- Q: One of my valves leaks a small amount of water through the valve and into the water line. why would it leak and what do i have to do to fix it. the valve is a rain jet valve. i would like to fix it without having to remove it from the valve box. inside the valve box there are 8 valves and they are glued in and i dont want to have to remove all of the valves and box.

- It depends on the type of leak. I recently had a leak (mea culpa four-pronged fork) and I was able to fix it by mounting an original hose clamp around it. If it is big you can use more than one hose clamp and perhaps a sheet of rubber or a part of the original hose in combination.

- Q: I am 31 and just discovered I have severe Mitral Valve Prolapse (Heart probelm). I probably have to have surgery. I have been healthy all my life and I am a little scared. Anyone had surgery for it? What can I expect??

- No okorder /.. If you look at the menu on the left of that page - it should answer most of your questions. Print it out if there are specific things you want to discuss with the cardiologist. Also be sure to click on the minimally invasive surgery Good luck.

Send your message to us

Gate Valve for Water System of China High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 60000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords