Gate Valve of Double orifice from China on Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Gate Valve Description:

1. Selected materials, in line with domestic and international standards, high overall quality of the material.

2. In line with the requirements of domestic and foreign advanced standards, reliable sealing, excellent performance, attractive appearance.

3. Sealing pair advanced and reasonable, gate and seat sealing surface with different hardness Stellite (Stellite) cobalt-based alloy cladding made, reliable sealing, high hardness, wear resistance, high temperature, corrosion good anti-abrasion performance, long life.

4. Stem quenched and nitride surface treatment, has good corrosion resistance, scratch resistance and abrasion resistance.

5. The use of flexible wedge gate structure, medium and large caliber set thrust bearings, friction force is small, and with a striking manually open and close with ease.

2. Main Features of the Gate Valve:

1)Full port design

2)OS&Y Outside screw and yoke .

3)BB. Bolted Bonnet .

4)Flexible wedge, Fully guided

5)Choice of solid or split wedge .

6)Renewable seat rings

7)Forged T-head stem

8)Rising stem and non-rising handwheel

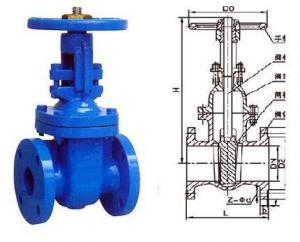

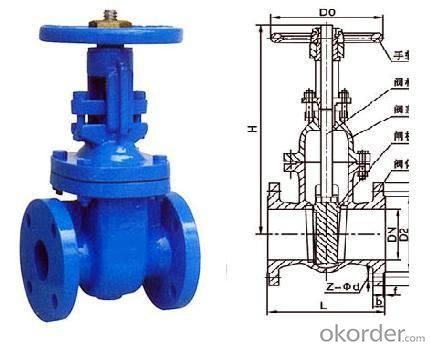

3. Images of the Gate Valve

4. Specification of the Gate valve

1.Material:A105,A105N,F304,F304L,F316,F316L,LF2,F5,F11,F22,F347,F321,F51,Monel......

2.Size:≤3"

3.Pressure: Class150~2500

4.Design and Manufacture:API602,BS5352,ANSI B16.34

5.Connection Ends:

1)Socket Welded Dimension:ANSI B16.11,JB/T1751

2)Screw Ends Dimension:ANSI B1.20,JB/T7306

3)Butt Welded:ANSI B16.25

4)Flanged Ends:ANSI B16.5,JB79

6.Test and Inspection:API598,GB/T13927,JB/T9092

7.Structure Features:

B.B(Bolted Bonnet) and OS&Y(Outside Screw and Yoke)

W.B(Welded Bonnet) and OS&Y(Outside Screw and Yoke)

5.FAQ

1. Can I get free samples?

A: Yes,we can provide you the free sample, but you need to bear their own delivery costs.

2. Can I request to change the form of packaging and transportation?

A:Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3. Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4. Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear

their own the cost.

- Q: For instance, I am buying some new tires that don't have the valve stems on them, so could I remove my existing valve stems from my used tires onto the new tires? Is this recommend at all? Is it safe? Is it possible? Can this be done? why or why not? thank you.

- Impossible. Tires don't have valve stems. Wheels do. For gosh sakes man, if your Mom ever taught you anything never re-use something that will eventually bite you in the butt. Old whipped out valve stems have tiny cracks which lead to leaks. It would cost you five times more than a simple valve stem if you had to break a tire down, replace a leaky valve stem, remount the tire, re-balance it and stick it back on the car. What is your economy $ thinking? Tell you what, if you ever see a tool for removing valve stems for re-use I'll eat it! Go hole hog and spend a big dollar or two and get past your idea.

- Q: Is it posible there is underground valves? I looked all over my yard and can only find2 valves.???

- Yes, electric valves are set on the Mainline which is under pressure. Usually in a loop around the home with the valves set where the zone starts. Some are designed to have a short mainline with the valves set in a large box next to a vacuum breaker. All valves need wires that run from the clock. Sorbet can be found with a metal detector if you simply can't find them. You can also set them to go off manually time delayed a few minutes, enough to go listen to hear the valve opening.

- Q: 2003 Ford Focus SE2.0L SPI EngineAutomatic Transmission 145KPerfectly maintained since new!One of the pistons had snapped, yes the actual piston, it didn't mess up the walls, but I am hearing a LOT about these dropping valve seatsI intended to do an entire rebuild with a kit, but did it break BECAUSE of a droppedvalve seat?I don't know because I don't know what that isHelp is appreciated

- Valve seat is the actual area on the head that the valve rests in when closed. Dropping a valve normally means that the keepers have come loose or a spring has broken and the valve has dropped into the cylinder. This was a common occurance when some one has modified an engine without upgrading the valve train especially in older engines.

- Q: what's the differences of American standard valve standard and Europe valve standard.Like API598 and ISO5208 , EN12266 valve inspection standard, or API600 valve design manufacture standard,and EN598,

- This Site Might Help You. RE: Is valve standard of API and ISO same? what's the differences of American standard valve standard and Europe valve standard. Like API598 and ISO5208 , EN12266 valve inspection standard, or API600 valve design manufacture standard,and EN598,

- Q: Also, Is a pneumatic control valve an ATC or an ATO; is it a FO or FC valve?

- When the individual ego is very high, directly relating itself to universal oneness is a difficult process, so he or she can get married and experience and grow with each other and than expand further. Such elaborate procedures are followed in ancient tantra philosophies. There there is no husband and wife tagging required, just two partners agree upon to help each others evolve and help each other as a subject in there experiment and practices. My brother coyote above makes this point very clear. -- Deito Harirnama Harirnama Harirnama Kevalam.

- Q: I was wondering if anyone knew how important tire valve stem caps were in maintaining inflation pressure in auto tires? I noticed one of my tires losing air slowly (from 30 psi to 21 psi in about a week) and this tire (unlike the other three) also had a missing tire valve stem cap. I've just replaced it, and was wondering if a missing valve stem cap caused faster loss of tire pressure.

- The valve caps main purpose is o keep dirt/debris out of the valve stem. if the valve inside were to leak due to not being tight or dirt holding it open the cap may prevent leaks. but if you refill that tire once a week, the dirt would have been forced in. replace the cap and see what happens. check the tire and valve stem with soapy water to help find the leak.

- Q: Hi all,My 1995 nissan altima (122k on the odometer) stalled for a few minutes this morning. I noticed that one of the sparkplug holes ( where the cable from the distributer connects to the spark plug) is sorrounded by oil. I cleaned it out and it got filled with oil again. luckily for me, and by god's grace it somehow started normally and i drove home. I am sure its the valve gasket. There is not much oil leakage, the oil level is fine.I need to know if its going to damage my engine if I ignored the problem for 3-4days.Thanks.

- Check okorder /

- Q: I jsut got my valve cover replaced on my car what does that do?

- it covers up the valves to keep the oil in the engine

- Q: I want a valve sound that is clean and 'true', but I also want pre-sets. Someone said that digital pre-sets distort the valve sound.

- First off, valves aren't meant to be clean or true. Technically the reason we like tubes is that they distort fairly easily, but in a pleasing and musical way (largely 2nd order, etc). Just being picky. =) Digital things can sound very digital in a tube amplifier depending on the quality of the DSP chip and how it's used. It looks like what they're doing in this case is modifying the gain values of the tubes digitally. This doesn't actually interfere with the signal itself. It's kinda like using a digital thermometer to control your heater instead of an analog one, or turning it on and off by hand - the heat still comes out, the method of when and how much comes out is all that changes. I'm very impressed with this amp. Whoever said that digital presets distort the valve sound were talking about something else - maybe the Line 6 Spider 3 or something, where the distortion doesn't come from the valves but from a DSP chip. Your amp there is a different beast completely. Saul

- Q: My brother is 32 years old.He has an enlarged heart ,a murmur,high blood pressure and heart regurgitation.He may be having the valve replacement surgery.I was wondering if anyone has had these things wrong with them and had the valve surgery and did well afterwards.Any information would be very much appreciated.

- Which valve is getting replaced (there are 4 in the heart)? Will he be getting a man made one (which will require life long blood thinners but are also very durable) or a pig valve (no need for blood thinners but won't last as long) ? Many people get valve replacements and it makes them feel wonderful afterwards.... make sure you find out about exactly the surgery he's having so you know... but I'm sure he'll be fine.

Send your message to us

Gate Valve of Double orifice from China on Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords