API Cast Steel Check Valve 450 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

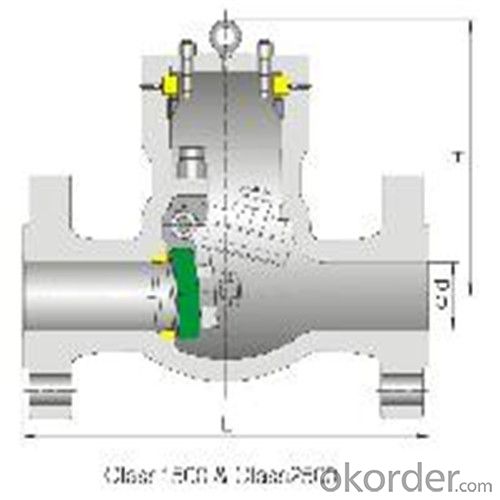

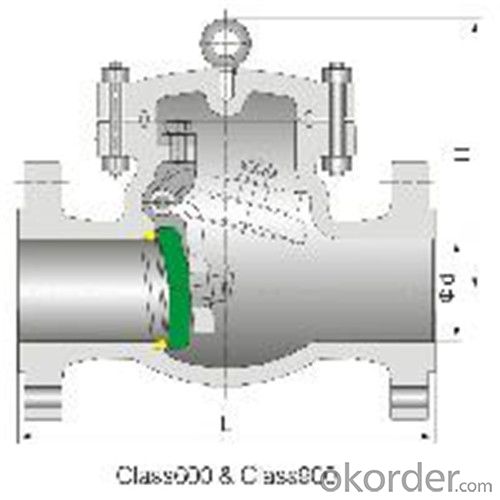

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: 2003 Ford Focus SE2.0L SPI EngineAutomatic Transmission 145KPerfectly maintained since new!One of the pistons had snapped, yes the actual piston, it didn't mess up the walls, but I am hearing a LOT about these dropping valve seatsI intended to do an entire rebuild with a kit, but did it break BECAUSE of a droppedvalve seat?I don't know because I don't know what that isHelp is appreciated

- I okorder /

- Q: I replaced the valve cover seal and I wanted to know the torque specs for the valve cover bolts and the sequence it should go

- A followup question... if I have already tightened the valve cover down, most likely to the incorrect torque, then drove it around for a couple of miles then let it sit for a week. Will I be able to go back and loosen the valve cover then re-tighten them to torque specs or do I need to start with new gaskets? No sealant used. The gasket was the metal and rubber combo type.

- Q: A friend of mine who is 26, was just told by her doctor that she has aenlarged heart valve. Is this really serious? Will she need surgery? Why can't I find any info on the internet? Please help I'm really worried. Thanks

- there are two valves in the heart, a bicuspid valve (two flaps) and a tricuspid valve (three flaps). A valve serves to prevent the back flow of blood in the heart, keeps it all flowing in one direction. An enlarged or incompetent valve would obviously be unable to do it's work properly. How serious the issue is depends entirely on the extent of enlargement. Enlargement is usually a result of uncontrolled blood pressure issues, but can also be genetic. As she is seeing a doctor about this, suggest that you let the doctor worry about it.

- Q: I have a '98 Dodge Caravan 3.0 and the valve cover gasket is bad. How do I replace it?

- take the bolts off pull off old cover and do the same with new cover!

- Q: Just wanted to know what the significance of the number of valves is?I know that theres valves for intake and exhaust if i'm correct.if there is four i'm guessing its 1 for air and 1 for fuel if its fuel injected. and 2 for exhaust?are there bikes with 3 valves or more than 4 valves and why?and a basic carburated 2 stroke just has an intake from the carb side and then an exhaust.please give me more info and let me know if i'm correct or not.

- 4 valves 2 intake 2 exhaust some single cylinder bikes have 5 2 intake 3 exhaust a 2 stroke engine has 0 valves they have an intake and exhaust port cut into the piston

- Q: I got a cold air intake installed on my vehicle and don't have any AEM bypass valve installed, for preventing hydrolock. If I drill a small hole(e.g 1cm) on the intake(short ram section) can that prevent hydrolock or do I still have to get one of those bypass valves?I'm looking for any alternatives, instead of those AEM bypass valves and was wondering if drilling a small hole in the cold air intake could help in preventing hydrolock, just as good as the AEM bypass valve.

- I okorder (i think thats it) for them, Im pretty sure thats where I saw them. Whatever you do though, dont drill a hole in it.

- Q: I own a 2wheel drive 2003 Hyundai Santa Fe 4cly. The engine light was on the code P0401 came up which is the EGR valve. I had it changed out the engine light came back on after I had made it almost home. I took it to auto zone same code came up that made me take to the shop for repair in the 1st place. Ugh. Please help! What's the problem???

- My vehicle is throwing a P0401 code. I was going to replace it, but instead I am going to clean it and replace it. I know the mechanic will want to replace it and charge me well over $100 (I'm seeing the part go for around $52-$55). THe car was recently serviced with the valve cover gasket replaced.

- Q: 1991 Buick Spirit smokes early for five minutes in morning, from exhaust. Tried every carburator and gas cleanative fluid. Mechanic says Valve job'.

- Probably just the valve stem seals need replacing. NOT a entire 'valve job'. The seals help scrape oil off of valve stem to lower the amount of oil weeping into cylinder when engine is running or turned off. As the rubber ages, it cracks and loses its elasticity and doesn't wipe the stem properly. This is a lot cheaper versus a full 3-angle valve job which requires removal of the heads.. Get a second opinion.

- Q: How would this affect the functioning of the heart valves?How would this be detected in a routine examination?

- Endocarditis is usually caused by bacteria. When symptoms are prevalent, blood cultures are done to detect what sort of bacteria is present. Many types of bacteria can cause endocarditis. Normally, blood flows smoothly through heart valves. But if they have been damaged, by some other medical condition, defense mechanisms (such as white blood cells) cannot enter the valves. Then bacteria can have a chance to take a hold on these valves. So if bacteria establishes a hold on the valves, the body cannot get rid of them. Antibiotics can be used to treat the infection. If antibiotics does not work, then the infected valves are removed surgically and replaced with transplants or artificial valves. I hope this helps. good luck

- Q: I have a Tippmann A5 and I removed the gasline from the tombstone and when i went to put it back in the valve washer is in the way. Please help

- When reinstalling the Tombstone it is best to position the marker barrel down this way gravity helps to keep the valve assembly in place. If the washer is dislodged you are probably also missing the large valve o-ring which sets on top of the washer. If the valve spring is setting past the valve body you will need to push it back down (use a small hex wrench). Set the washer on top then with the small hex wench press in the large valve o-ring on top of the washer then the tombstone should fit.

Send your message to us

API Cast Steel Check Valve 450 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords