API Cast Steel Check Valve 400 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

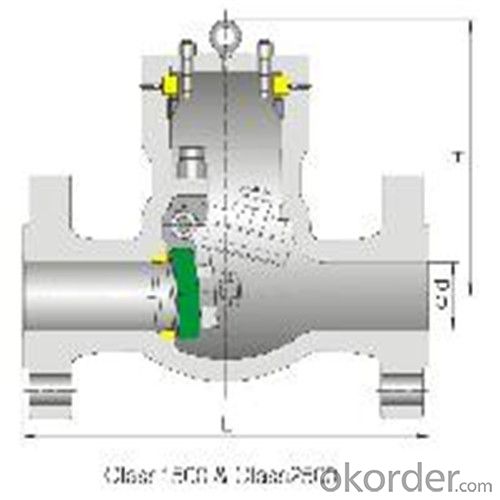

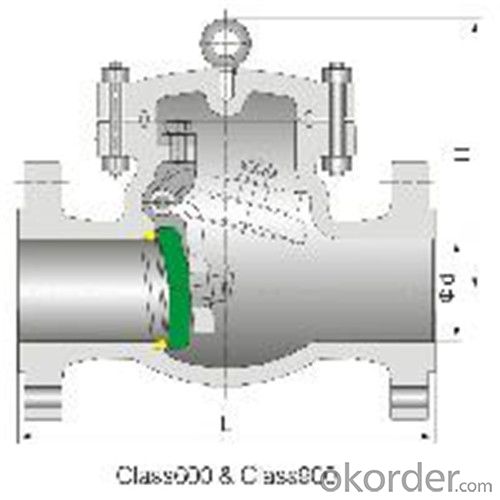

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check="" valves="" and="" welded="" on="" seat="" can="" be="" also="" optional="" if="" being="" requested="" by="" the="" customer.welded="" is="" used="" for="" nps="">12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: compare the structure of the tricuspid valve with that of the pulmonary valve??please help me

- Structure Of Pulmonary Valve

- Q: My 4.0 L V6 2002 Ford Explorer has this plastic casing on top of the intake manifold...some of the hoses (brake booster, etc) are actually connected to the plastic casing, now how can i replace my pcv valve?

- Try okorder

- Q: My car may have warped valves. What does this mean? Can it be fixed? If so about how much? And how does this happen in the first place? Anything helps! Thanks!

- Warped Valves? I take it you are talking about the engine? {May you mean Bent Valve Steams?} is the Head(s) apart and you have seen this? If it is Bent Steams there is no fix, Replace Valves Valve Guides. [Did some guess at this? the only real way to tell is have the head(s) off]

- Q: what do the doctors do and is it dangerouse? aslo how do you get a cloged valve?

- they are dangerous and you get them sometimes form cholesterol and stuff, the doctors clean it out sometimes unless you are in real danger when you have it removed

- Q: 1. Why is there an exaust valve. Isnt it only a port. Where do the gases that go into the exaust valve go?2. How does air enter the intake valve. If you look at a push rod diagram, you cant see where the air is enteringCan someone explain to me the valve concept

- You're not dumb for trying to learn. In a 4 stroke engine the air goes into the intake manifold and into the intake ports on the head. There it interacts with the valve, which when opened allows the air to be drawn into the cylinder. Then the engine goes through the power stroke and then the exhaust is forced out through the exhaust valve.

- Q: I jsut got my valve cover replaced on my car what does that do?

- Usually only the valve cover gasket needs to be replaced (unless you somehow damaged the valve cover itself). It does just what it says. It is the metal(2) located on the top of you engine that covers the valves. It needs to be replaced when the seals are allowing oil to come out.

- Q: I have a T4-T10 and L5-S1 spinal injury and I recently found out that my tricuspid and my mitral valves leak. I have never had heart problems before I got the spinal injury. Do you think the valve leaks could have been from the trauma when I received the spinal injury?

- Maybe but usually MVP doesnt give people much problems and if it does usually sudden

- Q: My boyfriend is getting mitral valve replacement surgery soon, he is getting a mechanical valve put in.Has anyone had this surgery done? What are the risks. Anything else need to know about this surgery that is important. Im just worried about the surgery wanting to know as much as I can to be prepared. thank you

- Haven't had it done before but: It's a pretty involved procedure. Patient is put under general anesthesia and is usually on the cardiopulmonary bypass machine (heart-lung machine) since you can't really replace a heart valve if the heart is beating. mortality for full valve replacement according to wiki is 6-8 percent, prob less than 5% for young healthy patients. Recently, many people have been doing the procedure laparoscopically. Patients are put into the surgical ICU for typically 1-2 days after the surgery. You can be discharged about a week after. Obviously there's risks, this is a very involved and definitely not a simple procedure. However, the cardiothoracic surgeons do these procedures every day for their entire lives-they're very skilled and qualified. good luck!

- Q: how to replace a valve cover gasket on a 98 pontiac sunfire 2.2. engine?

- First off, you remove the PCV hose and unscrew the plastic nut that retains the PCV valve. Next you remove the air intake tube from the throttle body and the air intake housing. Now locate the bracket on the side of the throttle body that contains the throttle cable. Remove the 2 bolts from this bracket and remove the cables from the throttle body. You should now be able to remove the valve cover from any obstructions. If you are not cleaning the valve cover, there is no need to remove the PCV valve. If you are cleaning it with soap and water, take the PCV out. The gasket is one piece and rubber, but you may find it a pain to keep the gasket in the groove on the valve cover, so you might try some yellow weatherstrip sealer to help hold the gasket in place. Let it dry for a little while before reinstalling the valve cover, so the gasket doesn't 'roll' out of the groove on the corners, or it will leak heavily. Good luck.

- Q: I am 31 and just discovered I have severe Mitral Valve Prolapse (Heart probelm). I probably have to have surgery. I have been healthy all my life and I am a little scared. Anyone had surgery for it? What can I expect??

- yes. In Feb of last year. Had a gradually worsening valve and regurg. Had it done at UVA teaching hospital by an excellent surgeon and 2 doctors who were months away from being certified themselves. IN at 6 am, spent most of the day in surgery, stopped my heart, cut open my breastbone, opened my heart, sewed in a ring and trimmed the valve, closed and restarted. Spent a week in hospital; three weeks at home recovering and was released to come back to work at a very low physical demand (and driving a car with no airbags). Couldn't lift or pull anything for a good six months being cautious mostly about the wires holding my breastbone together. Was on blood thinner for about 45 days and on severe pain meds for about 30. HAd a little fluid develop on a lung that eventually cleared, and some anemia issues that also creared up. After 6 month, my cardio told me it went well enough I didn't have to see him again. Year later, only real side effect is some residual fatigue (im 51) and my breastbone gets sore when I'm tired or overstressed. I'm not a smoker and they said this was textbook. No worries man; you'll blow thru it

Send your message to us

API Cast Steel Check Valve 400 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords