API Cast Steel Check Valve 500 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

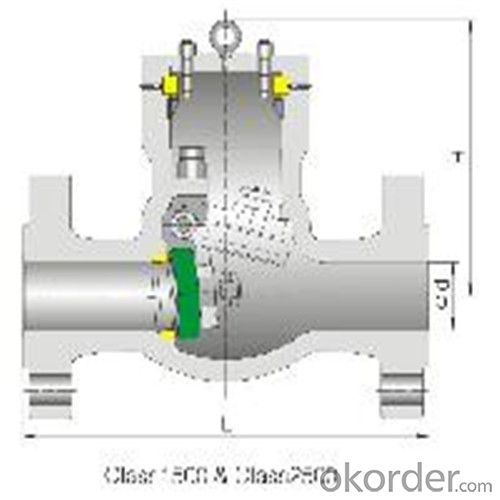

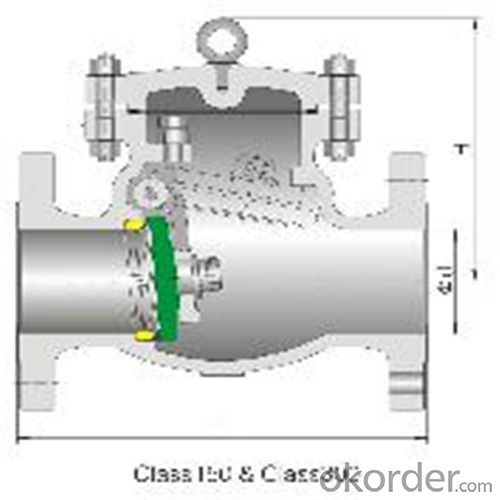

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I was told on Tuesday that i have mitral valve prolapse and that i inherited it and that i will be fine. Well i take toporol xl 50 mg because the mitral valve prolapse makes my heart beat fast. For the past week i have noticed that my chest/lungs get tight, kind of like i have congestion in my chest, it comes and goes and sometimes its really bad and sometimes i can tolerate it. Is this normal for someone with the mitral valve condition. My cardiologist didn't go into details about the symptoms and i'm wondering if i should go see another doctor. I do have a sniffly nose and was wondering if this could be symptoms of a cold or something else. Any one out their with my condition having the same problems??? If so what is it???

- I also have this condition and I also take Toprol every day. If I forget to take it I know by noon I didn't. My heart really runs fast. I also have the tightness in my chest. AT times i feel like my heart is turning over, now that is weird. I am with you on not knowing what to do, one Dr says leave it alone another says fix it. I am not much help but I understand your thoughts.

- Q: i have a 1986 Ford Mustang 3.8L V6 automatic. i need to change to valve cover gaskets but im not sure if i can do it. what do i need to do? and do i need to ad something else other than new gaskets? thanks

- Take your time when changing the gaskets. You will more than likely have to disconnect things. Make sure if you remove something it is put back. If you have to remove the spark plug wires, number them. From front to back, the left side is 1-3-5-7 and the right side front to back 2-4-6-8. I mark my wires with a sharpie but they are red wires. I use to use wooden clothes pins and write the number on the clothes pins. If you get the wires mixed up you'll have to get the firing order to get them back to the right cylinder. Good luck, you will appreciate your vehicle more now that you know the work is done right.

- Q: What are the function of reed valves on a motorcycle?

- Reed Valves

- Q: My grandfather is going in for a valve replacement.. and I'm really worried about him.. I just want some information.. any good websites if you have them.. I looked on google.. But if you have any good ones that would be great..No horrible comments please..

- sorry okorder

- Q: I have an old trumpet valve stem that will not screw in the valve cap. I ordered a new one but I'm not sure how to remove the old one and put the new one on without doing anything that would influence the look and playing. HELP!!! Professionals are welcome and others. I don't have any professional technicians near by .Summer band is starting up so I need this FAST.

- I hope you have a Bach trumpet, because each valve stem is specific to a particular maker and even to specific models. So, if you don't have a Bach trumpet it is very likely that the stem won't fit. If you cannot remove the valve stem with your hands you can try soaking the joint with oil and/or warm water and dishwasher detergent. You should give yourself a couple of days to see if you can loosen them up. Do not use tools--no screwdrivers, no pliers, no vices, no strap wrenches--if you don't know what you're doing you stand to damage the very fragile valve. You may need to take it to a tech--remember you're trying to avoid a $100+ dollar bill for repairing a damaged valve.

- Q: here are pix's i want to no, if there is a easy fix or does it have 2 b machined thanksi think it use to have a bent valve in it

- hard to tell looking at your pic,s. your best bet is to find a trust worthy machine shop...they can tell you if they can be lapped or if they need replacing...newer heads have hardened valve,s seat,s..if damaged they should be replaced ...valve,s , seat,s , guide,s , valve seal,s , possible rocker assembly,s , lifter,s , push rod,s ,Etc......best of luck!

- Q: I have a Ford Explorer 4x4 2004 model.The check engine light soon has been on for two to three weeks, I finally got it checked and they said i need my ERG valve cleaned. They quoted it for around 50 bucks, which is fine. However, i dont get paid until a week from now. Will it be alright until then?What are the effects of a dirty/faulty ERG valve if not taken care of??There are not sputtering or anything abnormal that i can tell..Thanks.

- If your truck runs, you can probably continue running it for a while (likely a long while), though you might pollute. If the EGR valve gets stuck open, it will drop your vacuum pressure radically. That will cause your engine to run roughly and inefficiently. If the EGR valve gets stuck closed, your smog system won't work right (you won't be recirculating the exhaust gas to re-burn pollutants. It is possible that the shop had no reason to tell you to clean the EGR valve. You might ask the mechanic if it is stuck open or closed. He might have suggested cleaning the EGR as preventive maintenance.

- Q: Hi everybody,I need some information about the operation of a double solenoid valve and how to control it using a PLC

- A double solenoid has two solenoids, and when voltage is supplied to one (and not the other) the valve shifts. Note that if voltage is supplied to both solenoids at the same time, the valve will stay in the position is was in (i.e. it won't shift since the solenoids will be working against each other). This is typically not desired, so make sure you remove voltage from one side when supplying it to the other. If no voltage is supplied to either solenoid, the result will be the same as if voltage is supplied to both, in that the valve will stay in the position is was in. What this means is that the cylinder has no home position, so when power is cut, the valve will stay where it was at that time, and the cylinder will continue to do work in the direction is was working in. Again, depending upon what the cylinder was doing, this may or may not be desired. For Conrolling with PLC you may need to wire two discrete outputs of PLC to those two solenoids using relay. And the ON/OFF those two outputs as required.

- Q: I have just been diagnosed with a Mitral Valve disorder. The Doc's notes say Trace Center Regurgitation. Also Trivial Tricuspid Regurgitation. In simple terms, what do these things mean, what causes it, and how do you treat it?

- If there is regurgitation but it's minimal, you likely have little to worry about. Mitral Valve disorder is commonly known as a heart murmur. Many people have them. It's only when there's regurgitation involved that it becomes more complicated. Since yours is trace and trivial it definitely requires investigation. At some point they may want to do a repair of the valve or a replacment but that depends on the degree of regurgitation. Regurgitation simply means that the valve does not close properly when the heart pumps out blood. It is the abnormal leaking of blood from the left ventricle, through the mitral valve, and into the left atrium, when the left ventricle contracts, i.e. there is regurgitation of blood back into the left atrium. Treatment will depend on the severity of the regurgitation so it's something you'll need to discuss with your doctor/specialist.

- Q: How would you change the Heater control valve on a 1997 honda civic hx?its my first car, so i dont know much about cars.

- Honda guy has the best answer, but I have a couple things to add. If it is like my daughter's 1993 Accord, it is easier to do from under the car than above it. In that case the converter heat shield is nearby and it badly cut my wrist when I tried to get the valve hose off the heater core - put a rag on that wicked thing. Be very gentle while wrestling the hose off the heater core pipe that sticks through the firewall - the pipe is thin brass and easily deformed. It is best to cut the hose lengthwise and peel it off, and be patient. You will want to replace that bit of hose anyway. EDIT - one more thing. After refilling the coolant, find the nipple (probably on the thermostat housing) for bleeding the trapped air out of the cooling system. Open it half a turn and close it when a steady stream of coolant comes out. Top up the radiator - remember, always use proper coolant diluted according to directions with purified water, never tap water. Life is good.

Send your message to us

API Cast Steel Check Valve 500 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords