API Cast Steel Check Valve 600 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

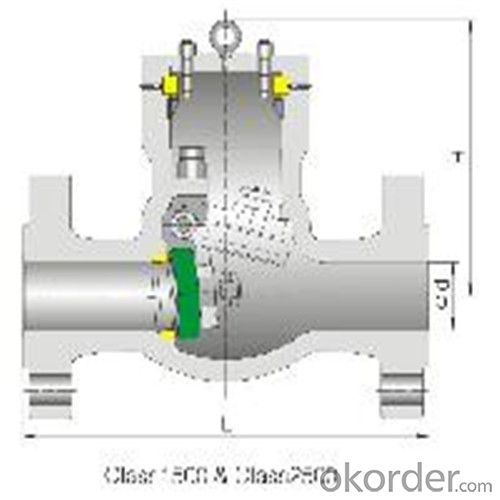

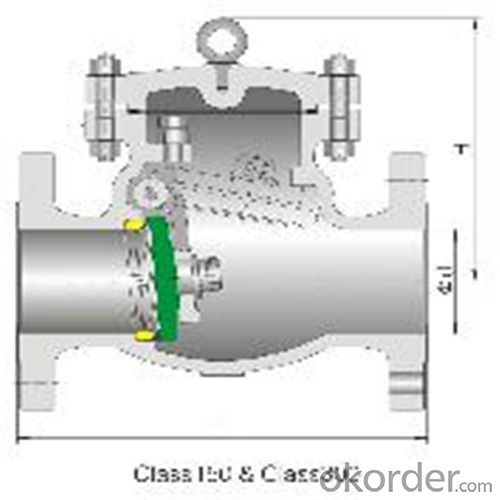

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Long story short, have a 2001 acura tl had a rough idle/ no start issue. figured out by disconnecting vaccuum from the throttle body the idle was fine with the TB pulling air through the disconnected hose port. The hose i disconnected leads to the purge valve solenoid. I removed it and it is closed (no air flow), restarted car with hose disconnected and solenoid still harnessed in (still closed). Just need more info on the function of this thing and what it should be doing.. Can i bench test it with +12V and ground on the two pins? Thanks in advance.

- When okorder

- Q: I just installed three anti-siphon valves(jar top,orbit) for a sprinkler system the main water line is 3/4 then goes into my manifold (pvc)3/4 schedule 40,usually when you turn on the water it comes to a stop where you re valves begin then you either open them manually or their set up through you re timer, the problem im having when i open the main water line the water goes straight through the valves without me even opening them my question is can it be to much pressure or what can the problem be? any info helps thank you

- another thing that can cause this is when assembeling the manifold it got filled full of rocks that are holding the diaphrams open

- Q: Is this possible? The valve is way too big to fit the rim. Is there a special inner tube for this rim? Thanks in advance.

- There are two kinds of valves used on bicycles. The large one, the Schrader valve, is the same as the valve used on cars. The thinner one is the Presta valve. The only possible way to get into the situation you describe is to have a Schrader valve tube and a Presta valve rim. Take the tube back to where you bought it and exchange it for a Presta valve tube. Presta valves are easy to operate. To inflate them, remove the plastic cap if one is there. Fully loosen the fitting at the top of the valve. It will not come off. Inflate the tire to recommended pressure with a Presta valve pump, a pump that automatically does both valve types, or a threaded adapter that will let you use a Schrader valve pump (remove the adapter when done). Then, screw down the fitting that you loosened to start. You really don't need the plastic cap. Their purpose is the keep the valve from puncturing the tube when the whole thing is folded up. Once you've installed the tube in the tire you don't need the cap any more. HTH EDIT: (sorry for shouting) DO NOT DRILL OUT THE RIM! That has the potential for serious safety problems.

- Q: I believe my EGR valve is bad. I am having symptoms of a bad one. If I unplugged it and took my car for a drive would the symptoms improve, if in fact it is a bad EGR valve?

- there are testing procedures that can be found in any car repair manual. the simplest are the vacuum operated ones. the electrically operated ones are a little more difficult to test, but can be done

- Q: Hey I'm high rite now and i have a checkup for mitro-valve prolapse tomrow, i was wondering if they will take my blood and see THC in me....

- Mitral okorder

- Q: When my son was three I switched Dr's for him. The new doctor said has he always had a heart murmur I said no that's the first I've heard of it so we went for test. Anyway heart specialist did all tests said my son had Bav a valve disorder in the heart. He said it is very common. However everyone I've ever talked to has never heard of it. My question is does anyone have this what is your story and have you had to have your valve replaced. My son is very healthy active I'm just worried. Any help would be greatly appreciated....thank you!!

- it is a common cause of murmurs in children, and ordinarily they grow out of it, you can relax.

- Q: My vehicle has 160,000 miles and has burned 2 quarts of oil at 3000 miles. Someone told me to change the PCV valve because sometimes a bad PCV valve can cause oil consumption. I appreciate your assistance.

- A PVC valve, or anything else for that matter, for a vehicle with 160,000 miles on it that's losing that much oil is probably a bad investment... A rebuilt motor might be a good investment if the rest of the vehicle is sound. If you're not willing to do that, any other shiny new part you put on will end up in the junk yard.

- Q: Can I make a heat pump straight A/C ?Or some hints how to replace the reversing valve without reclaiming freon

- some reversing valves(solenoid coils) are energized in heating some are energized in cooling. if it's energized in heat and u remove the coil it becomes straight cool if it's stuck in the heating position it's a heater and you will have to change the valve to get any cooling which will require recovering the freon.

- Q: i got a filler neck for my dodge dakota and was wondering how to put it on. can anyone send me a link or help me. and also what does my EGR valve look like and i cant seem to find a new one not even at the dealer. i was told to clean it how do i do this. can someone send me a link or pic what it look like. thanks

- The VECI decal map under your hodd will show you EXACTLY where your EGR valve is. You may need a magnifying glass. The valve can be removed and cleaned with Gum-out or foaming cleaner (amsoil). When you are done, re-install the valve. While you are getting ambitious, clean your throttle body and plate, and the IDLE AIR CONTROL VALVE. A dirty IAC is the most prominant reason for the EGR valve to clog up. Running Gum-out through your intake system will clean out your O2 sensors, as well. Good luck!!

Send your message to us

API Cast Steel Check Valve 600 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords