API Cast Steel Check Valve 600 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

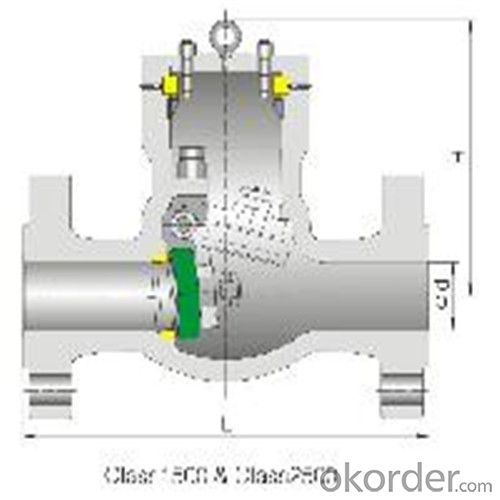

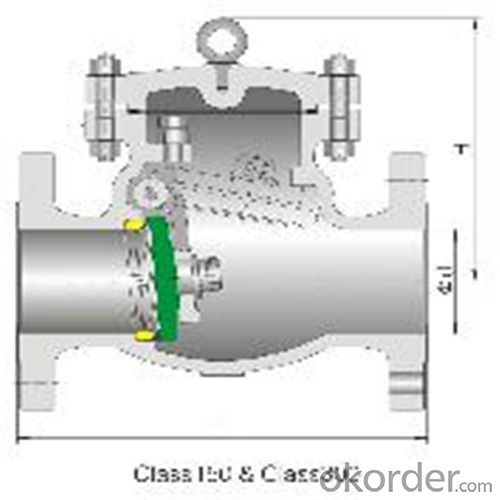

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: problem seems like a bad IAC valve - When I start it, it runs at 2000 for 10 sec then starts varying between 1000 2000 rpm at idle. Over 2400 it is level. If I pull the connector it will vary quickly around 1500 rpm as soon as it is started. Cold or hot no difference. 10 sec delay will happen every time it is started.I just replaced the air cleaner and cleaned the PCV valve, which seems to work about the same as a new one, then this started. Coincidence or something else wrong - like an air leak? How can I be sure it is the IAC??I've pulled the air intake and plugged the bottom throttle port and it goes to idle. the only trouble code is 0505 unless of course I pull the connector. Pulling the throttle position sensor plug yields a constant 2000 rpm and an code indicating it is open.thanks.

- iac valve common to fail on odysee also has problem with the wires to the power steering pressure switch pulling out of the connector causing idle to fluctuate lightly pull on wires to check for bad connection switch is in the power steering pressure line pass. side of car on back side of engine

- Q: I have a 87 cbr600, consumes oil at a considerable rate. Took the engine out of the frame and disassembled cylinder head, block and pistons and found there is a thick layer of cooked-on oil over all sixteen valves. I figured the oil consumption was due to bad rings, but could it have been the valves?

- Valve guides and seals will, but not the valves. Bad valves will lower compression on the engine and reduce performance but won't burn oil. The deposits on the valves are most likely from oil burning, getting to the heads past the piston rings. The rings aren't hard to change if you already have the head off... pull the cylinder block off and the pistons will be accessible. Getting the block back on can be tricky as you have to get the rings compressed. Might take two or three people. Good luck. Reassembly is harder than disassembly, but you probably already know that. Make sure you get the cam marks exactly right!

- Q: compare the structure of the tricuspid valve with that of the pulmonary valve??please help me

- Hello Inga, I'll help you this way. Form Follows Function. Remember that as you learn anatomy. It will guide you, make sense out of confusing things. In this instance, those two valves are not the same. They have very different requirements. Understanding the structural functioning of the heart will make this clear to you. Go back to the text, reread this section. Ask yourself. What are the differences between these compartments? Once you've an understanding of the cardiac cycle. You'll see ( hence remember it) for yourself.

- Q: I need the valves that I need to press down for the notes on the bass stave. Can someone please write them down for me in a list like this?F = openG = 1 and 3A = 1 and 2 etc.Thanks people.

- I'm sorry I don't play the tuba and so I don't know, but please don't refer to a tuba player as a tubarist! I mean, I got a good laugh, but that isn't a word. They're called, tubists.

- Q: The hot water shutoff valve to the washing machine was dripping. I removed the packing nut and put in new packing over the weekend. Problem is that the packing nut seems to only go back on at an angle no matter what I do...it may have already been that way though. The valve isn't currently dripping, but I'm not liking the way the packing nut only goes on at an angle. Would it be crazy to keep the existing valve if I keep an eye on it and over time it doesn't drip, or is it too risky to keep this valve given that the packing nut is on at a funny angle? (Local plumbers here in Northern NJ all want around $350 if I were to replace both the hot and cold with a watts single handle valve.) Thanks, J.

- I would do a little more trying to get the nut on straight. Turn it counter-clockwise until it drops a little bit. Then turn it clockwise. Question to ask yourself is, how long will it take you to get to the main house shutoff valve if the nut lets go? You should be able to replace just the one faucet for less than $10.

- Q: i have a zone that - when turnd on by timer or manually only about 1 foot of spray comes out of sprinkler heads (used to wk fine). When i turn the ittle screw on top of valve (its about the size of a dime) water pressure comes up and wks fine - only water leaks at screw and when zone comes on next time NO pressure??? metal valves were just replaces about 1 yr ago.

- No. that's not gas tight and the plastic factors would possibly no longer delight in the petroleum ecosystem. you will choose a valve it is meant for propane. And the suitable valve would matter on the rigidity the place you meant to place in the valve interior the line. you will additionally would desire to layout the entire element very intently - no open touch relays - to steer away from a spark that would spark off errant propane.

- Q: All i see is portal and l4d Valve must of discontineud Half life. Its been 6 years they should at least tell us the making the game. I guess this means half life is dead and the last one is ep.2 why valve? why? tell us its coming to xbox 360!

- Valve is pretty secretive about their game development. They have made no indication that they are not continuing the series, although last January, it was implied that they may skip Half-Life 2: Episode 3, and move on straight to Half-Life 3.

- Q: sprinkler valve leaking

- Most valves are either 3/4 or 1 with female connections. Use the same size male adaptors with teflon tape wraped around the threads and screw it into the valves. Take a photo before you start to refer to when rewiring.

- Q: Could my subs kill my EGR valve? I replaced my O2 sensor and my check engine light didn't go off. So I had it checked again and the same problem was still there. It said that all the cylinders were running either rich or lean..... I can't remember. But I was told it could be the EGR Valve so I replaced it and for about a week the check engine light was off.Now its back on. Had it checked again and the same deal was going on. Oh there was also a low voltage reading..... which is why I'm thinking its my subs.So could it be my subs that keeps killing my EGR valve? And any solutions will be helpful. I don't want to have to replace my alternator because its in an extremely tough place to reach. And I already have a small Cap.... .5. My subs handle 600 RMS total. WOuld getting a bigger Cap help?

- next time state year/make/model/mileage. most egr valves operate via vacuum. your subs can't affect a vacuum operated egr valve. if the o2 sensor didn't help out, you probably have a bad vacuum hose somewhere. that will cause the system to go into havoc because the car computer can't compensate for the excessive air being sucked in. a cap does not help with anything except for a loud THUMP. the THUMP causes a voltage spike and stresses the charging system. the cap takes care of the thump safer, it's not a complete solution.

- Q: If someone is not born with heart valve disease... can a teenager or a 12 year old develop heart valve disease?

- If a teen has heart valve disease, is most likely something they where born with, but it can go undiagnosed till the are teens. I was born with aortic stenosis, aortic regurgitation, bicuspid aortic valve(all are valve disease) and i also have an enlarged aorta. Im 16 years old. I was born with the bicuspid aortic valve and aortic stenosis, and that caused me to develop aortic regurgitation when i was 10, and an enlarged aorta at 14. In some cases a teen can develop it with out being born with it, its uncommon but it can happen.

Send your message to us

API Cast Steel Check Valve 600 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords