API Cast Steel Check Valve 300 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

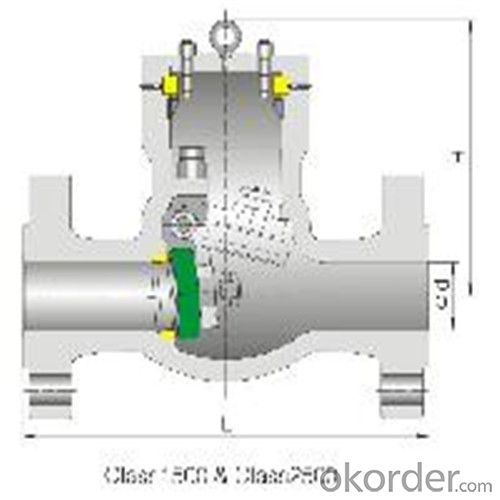

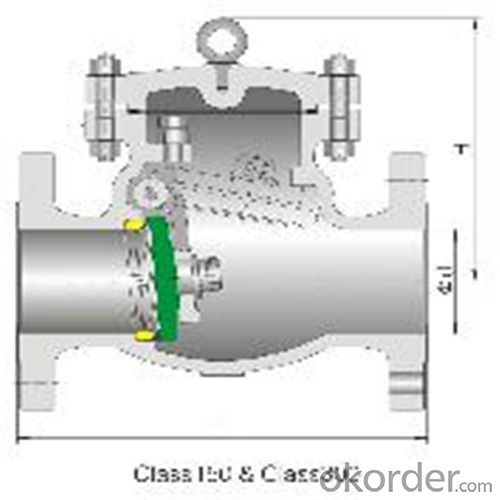

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I have a stainless valve I want to install in a copper domestic water line. My concern is: are the two metals compatible? Are stainless steel and galvanized steel compatible?

- I am a bit confused. You ask about nnecting Copper to stainless steel, then ask if Stainless steel is compatible with Galvanised steel. However to join Copper to stainless steel , you will need a special Flux which is only obtainable from a Plumbers merchant. That is if you need to solder them Together. If you dont solder them, Then , yes they are compatible.

- Q: is it possible to check valve to piston clearance with out taking the heads off? I want to buy a bigger camshaft for my 351 windsor stock pistons with 1970 heads. cam is 230 duration (280) and 512 lift

- The piston isn't the issue here, the issue would be the valve springs. Stock Ford small block springs will bind at .500 lift, this cam will require new springs. If you don't have adjustable rocker arms (most Fords are a postive stop or torque value) you will need an adjustable valve train also. 351s and 289s BOTH use 4 inch pistons, and you CAN'T put a 3.5 inch (351) crank in a 289!

- Q: ok im buying an aftermarket blow off valve for my car. the car itself is taken apart completely and i have no idea wht vacuum lines go where. i know tht the top nipple of the bov has to be connected to the throttle body but it has 5 lines. does it matter what line is connected to it?

- Don't do it. First of all, if you knew enough about turbo charging or supercharging, blow off valves, bypass values, hooters, etc., then you would have known we need to know the size of engine, model of turbo, piping diameter, etc. The actual control lines are not that complex. By using your tongue you can tell what each line is ported to, and then you just need to know if you blow off valve is operated by vacuum or lack of vacuum. They make both types. And your throttle body will have ports on both sides of the plate. And yes, it does very much matter. Turbo charging is not for the novice to fool around with.

- Q: How much would it cost to get a new valve cover gasket on a 1993 Nissan Quest van?? I know of a van for sale, but they said it might need a gasket soon. How much plus labor, average, do you think it'll cost? Thanks!!

- www.okorder /

- Q: how do u remove a valve seat from a head, and install the new one?

- What engine? Not all heads have valve seats that are pressed in. Some (many later model cars) have the seats ground right into the head and are not removable.

- Q: What is the purpose of the LNG Vs Propane Valve that has to be installed on Gas Stoves/Ovens before use ? How can I set it myself for Propane ? What negligible effects would I experience if I hook a stove up to Propane while the valve is set-up for LNG ?Thank You !

- LP gas and natural gas work off of two different pressures. Usually there will be a inner spring that need to be changed out inside the valve, and the orifice will need to be changed as well. If you don't convert your valve, it can prove to be very dangerous! Most likely it will only have an erratic flame, and burn very dirty. The flame will burn out of control and have orange color to it. However, it could result in not burning off all of the gases as they are released, and could cause an explosion. Most of the time in the owners manual it will have step by step instructions on converting LP to Nat, or vise versa. Remember, gas is a safe alternative to electricity, but if not handled correctly it can be very dangerous. Please proceed with care, or if you are uncertain with yourself, call a qualified technician. It shouldn't take em more than an hour, and most techs charge around 60 bucks an hour. A cheap price for a job done safely.

- Q: Ok i just be nt a valve on my 97 eclipse gst. I did a compression test and all my other cylinders were at 175psi which is good(thank god).My 3rd cylinder is only at 25psi.My mechanic will do the installation of the new valve but his friend has to do a valve job and re condition the whole head. Just because i guess your suppose to re condotion and clean the whiole head when this happens. What do u think a ball park estimate would be for this kind of work?I think he is going to replace all of the valves and seals y hes got the head off. The car has 100k on it and there is nothing else wrong with it. The guy i bought it from put a brand new bosch alternator and waterpump in and it also has a new timing belt so i dont have to worry about it skipping on me. WHAT DO YOU ALL THINK WHAT I SHOULD DO? HOW MUCH WILL IT BE? IS IT WORTH RECONDITIONING THE WHOLE HEAD? THX ALOT FOR YOUR INPUT.

- if a compression attempt is widespread then you certainly have not got a tendency valve to bend it it has to hit some thing like the piston and that's no longer exceptionally. have you ever run low on oil or crushed on her a splash? if it consistently knocks decrease than the comparable condition its probably piston appropriate. if it knocks each and every each and every now and then then its gasoline or ignition appropriate

- Q: How would you change the Heater control valve on a 1997 honda civic hx?its my first car, so i dont know much about cars.

- You have to take the whole dash apart. Not an easy job, and definitely not one for a novice.

- Q: I have a WRX. slightly modified. im getting some upgrades here soon. clutch, brakes, and catback exhaust. i have a blow off valve i bought a while back, but found out it was illegal here in cali. if you know about blow off valves, then respond. is it worth putting on? what are the consciences of having one illegally if noticed by cops? all i know is that it sounds bad ***! :)

- A blow off valve is a protection function combating something from exploding or combating your engine from stalling. in case you have a speedier and you're on finished throttle after which you abruptly permit flow and your throttle valve is in idle then the turbine remains generating boodt however the throttle valve does no longer permit all of it bypass springing up back tension. This back tension reasons the engine to stall. whilst the throttle valve is in idle after finished throttle distinctive tension after the thorttle valve after the manifold creates a vacuum lifting a spriing permitting the severe air to be discharged into the ambience or it is going back into the intake or speedier.

- Q: I own a 1982 Pontiac Firebird base model which has recently started leaking oil from its Proportioning Valve. I have looked all over the internet for a replacement, and it turns out GM has discontinued the part. Now im faced with difficult and risky task of attempting to fix it, or turn it over to a repair shop as a last resort. The valve seems to leak out of a small circle with a hole the size of a needle inside which was covered by a rubber gasket. I have no clue what this does, and how to repair it.

- First up is that the valve is not leaking oil, it is leaking brake fluid. That is bad. The proportioning valve controls the brake pressure to the rear brakes. Most of the braking is done with the front brakes and without the valve you could lock up the rear brakes on medium to hard stops and the rear end could loose traction, that would be a bad thing on a sharp turn. With that said please replace the valve I have never seen a repair kit for them. Have you looked at to GM for the part? They may also have knowledge on a conversion of the master cylinder with the valve built in.

Send your message to us

API Cast Steel Check Valve 300 Class in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords