API Cast Steel Check Valve 300 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

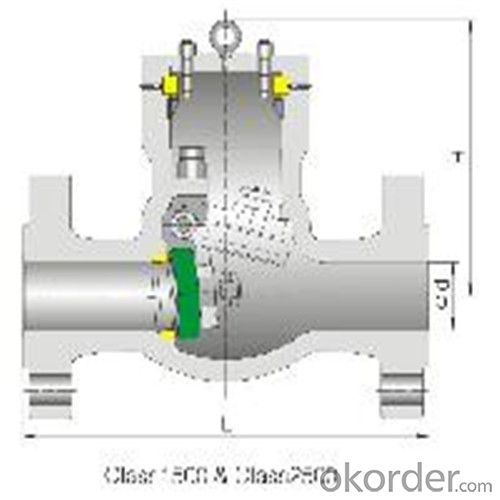

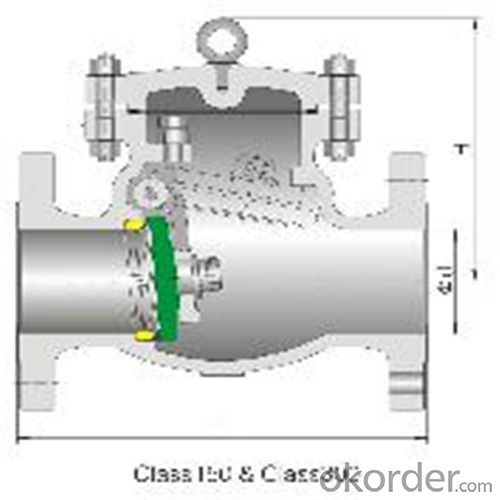

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: I was just wondering if any body got there valve replaced,and if they are still having symptoms..Such as sweating,and shortness of breath.I do not know if i should see a cardologist, or the surgeon who replaced the valve.Any answers would be appreciated.Thank you.

- Yes I just know a person just had that sugary like 4 weeks ago.Well after sugary he have to stayed in the hospital about 6 days. He going be out of work about 2 threw three months.He really tired and in a lot pain and he slept after heart surgy a lot and he doing well praise god!!!!!!!.If you have a problem of your heart you should to the Doctor you might have a heart attacked. i will pray for you.God bless u.hoped i helped

- Q: i was filling the tire on my car and the valve stem completely came out when i finished, quickly deflating the tire. i could push it back in but then the process repeated itself when i tried refilling it again. is there part of the stem i'm not seeing. the stem that i saw was long and straight and threaded. advise, thoughts? thanks.

- There is a disc shaped part of it that goes on the inside. It probably tore off and fell into the tire. Pick up a new valve stem at an auto store. They insert from the inside, so you'll have to loosen the tire bead in the valves vicinity. Lubricate it with soapy water to help with the insertion. Or, Take the wheel to a tire store and let them fix it.

- Q: We just got a new washer and cannot remove the old hoses from the pipes with the shut off valves on them. I don't want to bend or break anything. any suggestions?

- for really bad ones you can cut diagonally across the snout of the hose connector with a hacksaw until you just break thru. slow and gentle is the key here. this method removes even the most stubborn hoses.

- Q: The pump is working fine on the presta valve on my back tire, but it is not working on the other presta valve. It seems like the the presta valve isn't sticking out far enough out of the tube for the pump to be able to lock in on it. What could be causing this?

- to apply the adapter, you need to first unscrew the presta valve, then placed the adapter on and pump up the tire, then take the adapter off and tighten the presta valve to close it. I consider the different answer that that's recommended to replace the tubes so as that the presta valve does not come aside. New tubes are inexpensive - approximately $6 or so. you need to purchase a spare, too, merely in case you flat. in case you do no longer understand the thank you to alter the tubes, your community motorbike save can do this for you and clarify the technique so as which you're able to do it your self interior the destiny and sell you the tire levers (and patch kit in case you want) you will ought to do it. reliable success!

- Q: When using seafoam through the PCV valve. Which side contains the vacuum? From the crank case of intake manifold? The brake booster line is very difficult to access and on their site it says I can apply seafoam through the pcv valve.

- Remove the PCV valve from the rocker arm cover remove the hose off the PCV valve shake the valve, is it springy? if yes it is OK put it back on. If not spray the top and bottom holes and shake it back and forth till you can feel it becoming springy Best world I can think of sort of feels like a ball bouncing inside when it's free afterwords spray it till it's clean then dry it and install it bak into position. The hose is the vacuum side but you DO NOT want to get the sea foam into the booster diaphragm or it will damage it, it's made of rubber and ea form will harm it as will any oil or lubricants that gets on it. The PCV valve is a controlled vacuum leak and it pulls engine gas out and recreates it to burn again and it supplies boost to the brake system as well. Hope this helps.

- Q: Hey quick Q, I heard somewhere that you could degrease the the reed valve? I love cleaning up my CR250 as much as I can. I just want to know if this is done, and if you could, tell me where I'm supposed to clean.Thanks.

- The flow of gasoline rushing past the reeds is enough to keep them clean. No degreasing is necessary. Are you sure you didn't hear de-carbonize the power valve? If so, remove the power valve and linkage from the cylinder. Remove hardened deposits with a wire wheel on a bench grinder. Clean the parts with parts cleaner.

- Q: So the plug in the bathroom since fell in, coming off the attachment to open and close it from the top. When I got under the sink, I turned the shut off valves all the way to the right and the water stoped working. I unscrewed the attachment and fixed the plug (on the drain no the water) and when I turned the vlaves back on, no water. It dribbles just a little ifi turn the sink all the way on, however I cant get full water pressure. Any help?

- In some homes the place the sink is fixed to the wall, as on your case, there may be close off valves interior the basement at as quickly as under the bathing room. If there are none there then you certainly will maximum possibly ought to close off the main water the open the tub room sink faucets to empty off extra water. stable success.

- Q: My husband just found out that one of the heart valves is 100% blocked and the other 3 are 90% or more blocked . He is 78 years old he Is nearly non mobile. What kind of treatment would you suggest?

- A heart valve can't be 100% blocked. The heart simply couldn't function. On the other hand, coronary arteries can be blocked as you described. Normally, 4 vessel disease is treated with bypass surgery. In a high risk patient, angioplasty might be an option. However, if he is not having cardiac symptoms , or if he is thought to be TOO high risk, the option is medical treatment. Sit down for a talk with his cardiologist.

- Q: Dr says I have a leake heart valve. Should I be concerned?? He doesn't think so but I am worried. Should I get a second opinion? I am 53 and a diabetic. Has any one ever had this problem?

- I was diagnosed with a leaky heart valve at age 18, they did regular tests but only once a year, they then found an aortic aneurysm (bulging in main heart pipe) after many years i had surgery at 47 ! i came out of hospital 10 days after op. i am fitter than ever or i will be when i have my hip replacement later this year. so don't worry IF you have to have surgery its not that bad !

- Q: emission control valve toyota camry

- Is English your first language? Where is the question?

Send your message to us

API Cast Steel Check Valve 300 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords