API Cast Steel Check Valve 350 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

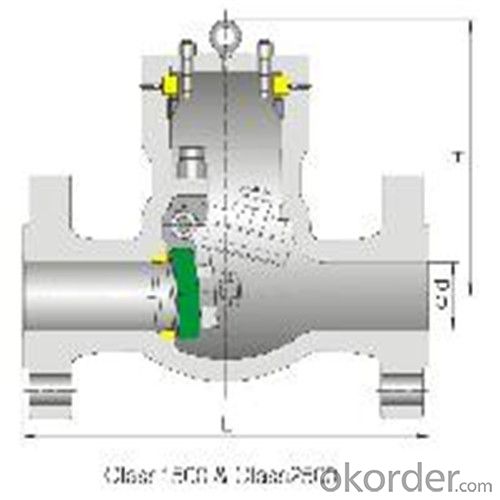

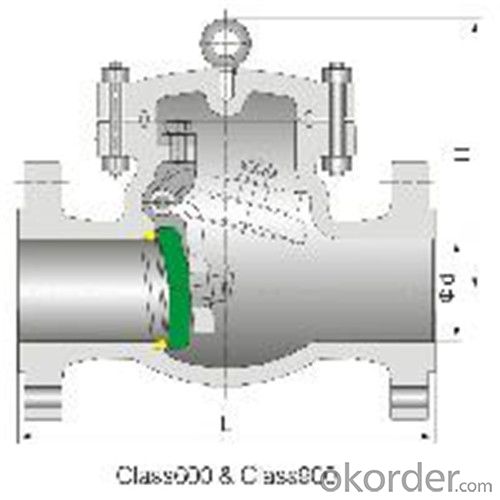

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Is there a more technically correct name for a valve that slowly opens, allowing increased pressure in a water line without blowing the end off?

- I've always known them to be simply called motorized valves, but they aren't specifically made to prevent instantaneous pressure build up. They are usually installed as a convenience type of thing and in lieu of solenoid valve which WOULD be an almost immediate full pressure situation, but any valve other than a solenoid activated one will allow for slow build up of pressure. A motorized valve just lets you do it automatically and you don't have to be right at the valve location to open it. Al

- Q: where is the oil pressure relief valve at in a 2003 ford focus

- its in oil pump some engines have a oil filter relief valve in behind the oil filter that can cause this problem but not certain if your engine does but worth a check

- Q: im looking at buying a 1995 ford probe, but it has a busted valve in the head, does anyone know how much it would cost to have fixed?

- When you say busted valve, do you mean a bent valve, or a broken valve? if you meant broken valve, i guarantee you my friend, that car is something that you do NOT want to invest your money into. a broken valve can cause and may have already caused all sorts of further damage. this can include exhaust fumes leaking into the cooling system and over-heating the engine, engine cylinder or gasket leaks causing oil to mix with coolant, broken timing belt, blown head gasket, and the list goes on. i HIGHLY recommend you stay clear of a broken valve. if you meant bent valve, this is generally not as serious, but is something to be very cautious of. the best way to check for a bent valve is to have a compression check done. a mechanic can do this, or you can do it yourself if you buy a compression checker. if the valve is indeed bent, the first thing you will want to find out is WHY it got bent. generally this happens because the timing belt slips or the valve has a leak from being stuck open. if this is the case, you might be looking at coughing up $300, maybe a little more, maybe a little less. but before dumping your money on fixing a bent valve, you want to get a professional inspection and make sure that this bent valve didn't cause damage to anything else. i hope this will help you with your question and with your decision on buying or not buying the car. good luck!

- Q: When using seafoam through the PCV valve. Which side contains the vacuum? From the crank case of intake manifold? The brake booster line is very difficult to access and on their site it says I can apply seafoam through the pcv valve.

- The PCV valve scavenges OIL VAPORS from the crankcase tthe VALVE COVER. Remove it and you will FEEL the vacuum when you put your thumb over it. It will POP the small pellet inside it. Foolow up with GUMOUT srpay and use BOTH to clean the THROTTLE BODY and the IDLE AIR CONTROL VALVE, the IAC is resonsible for mixing AIR with injecte4d fuel. A dirty IAC will RUIN mileage and clog up the converter. GOOD LUCK!!!

- Q: hii have just found out i have a genetic disease called multi valve prolapse but i want more info about itwhat are the symptoms? can it kill me? any info will help!!thank you

- Do you mean Mitral valve prolapse? The mitral valve helps blood on the left side of the heart flow in one direction. It closes to keep blood from moving backwards when the heart beats (contracts). Mitral valve prolapse is the term used when the valve does not close properly. It can be caused by many different things. Most people have no symptoms, but some people have chest pain, a rapid pulse, awareness of heartbeats, migraine headaches, fatigue, and dizziness. In a small number of cases, the prolapse can cause blood to leak backwards. This is called mitral regurgitation. Mitral valves that are structurally abnormal can raise the risk for bacterial infection. Some forms of mitral valve prolapse seem to be passed down through families (inherited). Mitral valve prolapse has been associated with other genetic disorders.

- Q: Is there a product that can fit over a foot valve to give it further protection in muddy water? I am looking for something for forest firefighting in mind. Something like a screen box something else that can give it further protection. It would be nice if it was small, and compact. Pictures would definitely be an asset. Thanks to everyone that answers. Greatly appreciated.

- most foot valves i have bought come with a strainer attached perhaps you should look for that type. if your valve has a strainer you may consider making a further coarse strainer out of a ball of chicken wire and place this over the foot valve assembly(thats what i do for the cold water supply to my house) don't compress the chicken wire very small as it will block up i tie the wire filter on with galvanized wire then i can easily replace it if necessary ps i tried stainless steel pot scourers but they were to fine and blocked easily

- Q: im looking for the egr valve on a 97 mazda 626 its not in top of engine like other cars where can it be?????o and its a 4 cylinder

- Dont know about your car, but look near the intake by the fuel rail

- Q: My Dr placed me in the care of a cardiologist who ran some test and an echo scan reports i have a leaking valve but she failed to tell me which one and i failed to even think to ask. What are the results of leaking heart valves? I asked my mother and she says each one has a different result. What are they? Any help would be great. thanks.

- i exchange into an open coronary heart RN. we frequently operated on people for the 2nd time, often desiring valve replacements. an consumer-friendly hassle after a 2nd time around open coronary heart surgical treatment is bleeding. the 1st 12 hours is extreme. countless those victims pull by using and do only extreme high quality. stable fulfillment with your Dad.

- Q: My boyfriend is getting mitral valve replacement surgery soon, he is getting a mechanical valve put in.Has anyone had this surgery done? What are the risks. Anything else need to know about this surgery that is important. Im just worried about the surgery wanting to know as much as I can to be prepared. thank you

- Haven't had it done before but: It's a pretty involved procedure. Patient is put under general anesthesia and is usually on the cardiopulmonary bypass machine (heart-lung machine) since you can't really replace a heart valve if the heart is beating. mortality for full valve replacement according to wiki is 6-8 percent, prob less than 5% for young healthy patients. Recently, many people have been doing the procedure laparoscopically. Patients are put into the surgical ICU for typically 1-2 days after the surgery. You can be discharged about a week after. Obviously there's risks, this is a very involved and definitely not a simple procedure. However, the cardiothoracic surgeons do these procedures every day for their entire lives-they're very skilled and qualified. good luck!

- Q: like my Acura has a 16v 4clyinder engine , and i dont know what valves does , the more vavles the faster?

- the more valves, the more complicated the engine, but yes, more power. a regular 4cyl engine has 8 valves, or 8V. 1 intake valve, 1 exhaust valve. (4x2=8) in a 16v engine, it can be 2 intake valves, 2 exhaust valves 4x(2x2)=16 there are engines with up to 32 valves, those are usually in the 8cyl engines. as a valve opens, it allows air into the combustion chamber, after the burn, the exhaust valve opens to let the burnt fuel out and thru the tailpipe. the faster the air can excape, the faster new air can enter. so more valves, more power. problem is, if they bend or break, very expensive to repair.

Send your message to us

API Cast Steel Check Valve 350 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords