API Cast Steel Check Valve 250 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

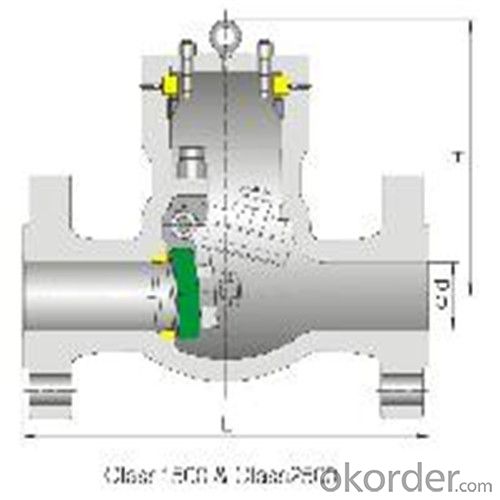

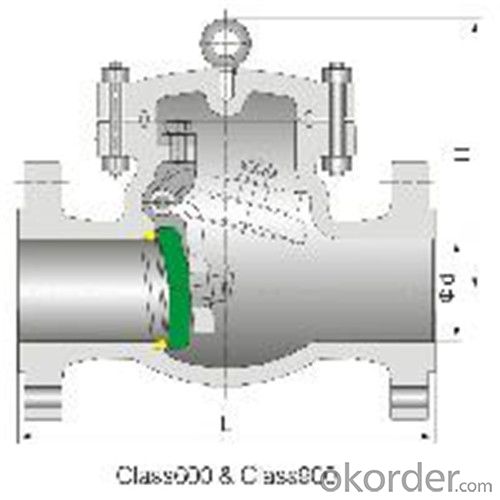

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: Bought a 1986 GMC 350day 1 started up good - idle was rough - idle really too low, when brakes where applied, it would backfire. (day 2) Changed oil which was really dark - oil filter too... ghanged spark plugs and wires. % 10 improvement... Engine lack power and vibrates but no more backfire.day 4 Changed Cap and rotor - % 30 improvement - day 5 Got the manifold gasket replaced. Same condition but silent... day 6 Changed coil in cap ... Changed fuel filter % 60 improvement... The thing ran like new... Full power I started beliving again..Got full oil pressure 300 kpa - no valve noise Ran 30 minutes on highway.... Valves started making noise especially on driver's side... Engine lost lots of power, and vibrates a lot... doesnt heat up to much but oil pressure seems very low. (day 7) Start up the thing, and even when cold and choke on, oil pressure not as good as in the beginning. What went wrong

- loosing oil pressure like that,it sounds like the oil pump.if the parts arent getting oil,it will loose power.also check the timing,it could be off and loosing power.if the timing is off,it will make the valves noisy.

- Q: I play the trumpet and I took it home for Christmas Break. On Friday I am playing Amazing Grace at Church for New Years Eve, but the problem is my valves on my Trumpet is sticking and I don't have any valve oil for it. Is there any other oil that I can use for the Valves? It will be really great! Thanks :)

- Pull it out and try saliva. Always worked for me

- Q: The shutoff valve for the hot water under my bathroom sink has a very tiny leak. It is coming from where the turn knob meets the valve.So long as the valve is either all the way open or all the way closed, all I get is a single drop every couple seconds. But if it is anywhere in-between, it is a pretty steady drip.What's the simple/quick fix for this? Replacing the entire shutoff valve is probably not an option because it is an apartment complex.

- In this case, the terms simple and quick do not apply. What's happening is the valve packing gland is leaking. That's the seal around the valve handle that keeps the valve from doing what it's doing now. The valve needs to be replaced--period! It is actually the simplest and quickest fix for the problem. Of course the water will need to be shut off while it's being replaced. The good news is that a competent plumber can do it in fifteen minutes unless he runs into problems. Then, it can take up to 3/4 hour. Your landlord needs to address this issue.

- Q: A friend of mine who is 26, was just told by her doctor that she has aenlarged heart valve. Is this really serious? Will she need surgery? Why can't I find any info on the internet? Please help I'm really worried. Thanks

- I am a CCMA Look up the word Cardiomyopathy. This is the Medical Terminology for an Enlarged Heart Valve and Yes it is VERY serious. Best Wishes

- Q: Hi guys, Thanks for your advice. RandyK is right, my dad's GP told me that if we don't get the valve operation, his heart will swell in years time and might cause more complicated illness. Just let you know my dad had seen his cardiologists recently and had some scan or tests done. The results will be discuss in next appointment, they suggested that mechanical valve would be used if the operation go ahead. At the mean time I just hope and pray his condition will under control by medication. Wendy, may I ask you how old are you when you had your valve operation? I am too scare to suggest or encourage my dad to do the operation. Because if there is any difficulties or worse ...during operation, I will be the one send him away......If anyone have a relative like my dad's case,(76 years old had valve operation) please give me some advice.. Many thanks

- Hi David, just saw your post. I was young when I had my valve replaced. I was 37, now am 42. My mother had her valve replaced at the age of 54. Honestly, that is the oldest person I know of that has had valve replacement. As with any surgery, there are alot of risks young or old. The older a person is though it may be tougher especially if he has a lot of other health problems. Just take all of this into consideration when you and your father are discussing all the details, etc. and find out any and all options that he has before proceeding with surgery. Best wishes to you both.

- Q: I recently adjusted the valves and put new valve covers on my bug and now I have a leak around the fron corner of one of my valve covers. What happened? What can I do?

- probably the gasket slipped or the bolts need to be tighten more but just snug them down.

- Q: Hi there - We have an old house with galvanized steel pipes. Our main water shut off valve leaks -- the leak is from the packing nut. A plumber came out yesterday and tightened it, and it now barely leaks at all, maybe one drip every 24-48 hours (which it probably has been doing for the 6 years we have lived here, we just didn't know when we bought the place). Rather than replacing the whole valve (which, apparently, has a high liklihood of breaking the pipes in the foundation, requiring jackhammering and whatnot), we are thinking of installing a new shut off valve higher up on the pipe, where I guess it's less likely to break. If we go for the second valve, is there a way to close up that old valve (hydraulic cement, tape, solder, etc.), so it doesn't leak at all? The tiny leak is coming from the stem of the handle - can we remove the handle and cap it off or something? (And thanks to those of you who answered my husband's question about the pipes yesterday!)

- with my background in replacing galvy with copper or even new galvy is not that your problem is fixing the old valve, but replacing that one with a new one and new lines to the house. your first problem is is there another shutoff at the street meter and if so, shut it off and replace from the meter to the house and add new ball valve at the street on your property and another at the house before entering the foundation. getting through the foundation is a whiz as the removal of the old pipe will enlarge the hole enough to allow new pipes to enter. on the inside, install another gate or ball valve if accessible so you thru a basement and then feed copper throughout the home. The electrolysis that the other person is speaking of is a valid point, but i believe in doing thing right. add a union between the galvy copper (6.00) and forget about it . sometimes if you have a lot of iron in your water, rusting will start in a year and destroy your couplings...so do it right.

- Q: what to use to inflate self sealing tube with the presta valve?

- Gazoo If you do not have a pump that will accept a presta valve, then you can either buy a presta schrader pump, or a presta valve adapter. I have an adapter in each of my seat bags, they are only a buck or so, and will allow you to use service station air on your trips. Just cause you may not know, the presta valve has a rotating screw inside the valve. So to add or release air you must take your fingers and twist on that knurled circular end so that the presta valve extends away from the valve stem. Then when the tube is filled, twist it back tight to seal it off. Soccerref

- Q: My third valve won't move at all. I haven't played my trumpet in a while and I tried to oil it to get it to unstick but it still won't move at all. People say to screw it off but I can only unscrew the little cap at the bottom of the valve where you push in, not the white button at the top. Help please! Thank you so much! =]

- i got here across that Dennis Wick valve oil is a procedures more advantageous ideal to any that I easily have used. you'll locate it on Amazon. If cleansing with dish cleansing soap and heat water would not artwork, alongside with the Dennis Wick oil, I recommend that you're taking it to a restoration shop. be careful at the same time as cleansing now to not get any cork or felt moist. only dip the truly valve section into the water.

- Q: I've just been told that I need to replace the valve cover gasket on my 97 Volvo 850.....to the tune of $650.00 .....ouch.....is it that difficult to fix?......can you use the red gasket sealant? is there a difference between the head gasket and the valve cover gasket.......yeah I know there probably is.......but when I look on line all i can find is head gaskets......no valve cover gaskets........which scares me into thinking they are the same thing.....i'm hopeing i'm wrong......if its the valve cover gasket it looks like it would be right on top of the engine and fairly accessable.......or am I wrong......sure would like to save the $650 if it is something i can do myself!!!!

- valve covers are easy to remove and replace. don't pay 650 bucks for that. yes, you can use the red sealant, but I would suggest high temperature sealant, usually comes in black, it's oil resistant also. just move anything out of your way, unbolt the valve cover, clean the surfaces off the gasket will touch (cover and engine) apply gasket maker and re-attach.

Send your message to us

API Cast Steel Check Valve 250 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords