API Cast Steel Check Valve 200 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The features of check valve

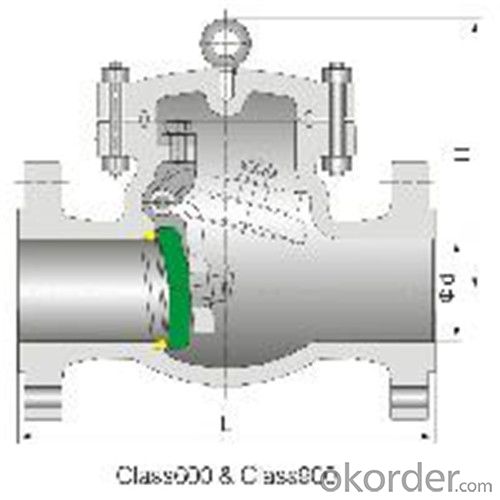

Bolted Bonnet;Swing and lift disc;Metallic seating surfaces.

Body and Bonnet Connection

The body and bonnet of Class150~Class900 check valves are usually with studs and nuts.And the body and bonnet of Class1500~Class2500 check valves are usually of pressurized seal design.

Body-To-Bonnet Joint

Stainless steel + flesible graphite wounded gasket is used for Class 150 and Class 300 check valve;Stainless steel + flexible graphite wounded gasket is used for Class 600 check valve,and joint gasket is also optional for Class 600 check valve;Ring joint gasket is used for Class900 check valve;Pressurized seal design is used for Class 1500~Class 2500 check valves.

Seat

For carbon steel check valve,the seat is usually forged steel.The sealing surface of the seat is spray welded with hard alloy specified by the customer.Renewable threaded seat is used for NPS<10 check valves ,and welded on seat can be also optional if being requested by the customer.Welded on seat is used for NPS>12 crbon steel gate valves .Forstainless steel check valve,integral seat is usually adopted ,or to weld hard alloy directly integrally.Threaded or welded on seat is also optional for stainless steel check valve if being requested by the customer.

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm 650 mm 700 mm 750 mm |

2 inch 2.5 inch 3 inch 4 inch 5 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 24 inch 26 inch 28 inch 30 inch customize | |

Actuator | Automatic customize |

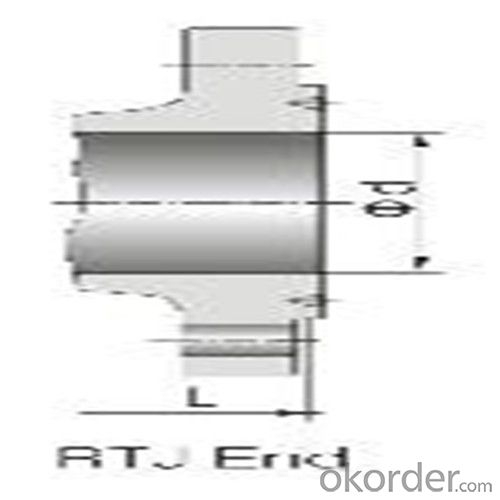

Connection | Butt Welding Flange RF Flange RTJ customize |

1-Body Material | A216 WCB A351-CF8 A351-CF8M customize |

2-Seat ring | A105+13Cr A351-CF8M A351-CF8 A105+Tool Steel customize |

3-Disc | 13Cr+A216 WCB A351-CF8 A351-CF8M Tool Steel+A216 WCB customize |

4-Arm | A351-CF8M A216 WCB A351-CF8 customize |

5-Nut | A194-8 A194 2H A194 8M customize |

6-Arm pin | A182-F316 A182-F6a A182-F304 customize |

7-Yoke | A351-CF8M A216 WCB A351-CF8 customize |

8-Bonnet nut | A194 2H A194 8M A194-8 customize |

9-Bonnet bolt | A193-B8 A193-B8M A193-B7 customize |

10-Bolt | A193-B8 A193-B7 A193-B8M customize |

11-Gasket | graphite+304 316+graphite customize |

12-Bonnet | A351-CF8 A216 WCB A351-CF8M customize |

13-Eye bolt | A181 customize |

Design Standard | API 6D BS 1868 customize |

Connection Standard | API 605 ASME B 16.25-2007 ASME B 16.47A ASME B 16.47B ASME B 16.5 MSS SP-44 customize |

Test Standard | API 598 API 6D customize |

Face to Face | ASME B 16.10 customize |

Pressure-temperature ratings | ASME B 16.34-2004 customize |

Wall thickness dimension | API 600 BS 1868 customize |

- Q: How do you clean an EGR valve on a 1999 Ford Taurus DOHC? What do I do and what can I use? Will water work? I've read a lot about a plunger mechanism but I have no idea what this is. Please explain in the best detail you can how to remove, clean, and re install the EGR valve?

- you don,t want to use water. the way i clean mine on my oldsmobile is i take it off and take a rag and some carburator cleaner and clean the bottom off where those little pintals are at. make sure the pintals work back and forth without sticking.

- Q: Arrange these structures in the order in which blood passes through them-assume the blood is about to leave the right atrium.Put in order:AortaAortic semilunar valveLeft atriumLeft ventricleLungsMitral valvePulmonary arteryPulmonary semilunar valveRight ventricle Superior/inferior vena cavaTissues of the bodyTricuspid valve

- Superior vena cava right atrium tricuspid valve right ventricle pulmonary valve pulmonary trunk (we actually refer to this as the main pulmonary artery) pulmonary arteries pulmonary capillaries pulmonary veins left atrium bicuspid valve (we refer to this as the mitral valve) left ventricle aortic valve aorta

- Q: can a person survive with only one heart valve functioning?

- Everyone has correctly identified that there are 4 heart valves. The question of survival is producing a variance in the responses. This may be because you do not define what you mean by 'not functioning'. People may do reasonably well - at least initially - with varying degrees of stenosis and / or regurgitation of more than 1 heart valve. So Yes in a sense if I understand your question correctly a person may survive at least temporarily with only one heart valve functioning perfectly. Please bear in mind that you have not given much information for me to work with in answering your question. If I may be of further assistance please let me know. I wish you the very best of health and happiness and in all things may God bless. JR

- Q: this question is related to Ball valves, In actuated valve for the selection of actuator we need differential pressure across the valve so I wanted to know that what is meant by differential pressure?

- differential pressure is simply having a different pressure each side of the valve. In this case I think that means you need a difference in pressure to move the ball closing the valve.

- Q: My eight month old daughter was just diagnosed with pulmonary valve stenosis. Anyone have an experience with this? Did you have cardiac catherization? Did that fix the problem?

- I had a different heart condition in high school. Mine was called superventricular tachicardia (SVT) but it required a cathedar in my heart. I had the ablasian surgery twice. We're not sure if it didnt work the first time or if there were two seperate problems, but after the second surgery I havent had any problems. Speak more to your doctor, he should be able to tell you more information and answer all of your questions. For me the surgery meant putting me to sleep and inserting the cathedar through three arteries, one on each side of my shoulders and one in the groin. I have very small scars that arent very noticable and I went home the next day.

- Q: I'm installing a shut off valve under my sink. can you tell me all the materials that i need to install it by myself because to hire some body else is very expensive where i live. i need to change the old ones because they are leaking very bad when i want to use the sink.thanks a lot

- It might just be the rubber gasket inside the valve You'll need: Screw driver to take off screw for handle, Adjustable wrench(Crescent, spanner etc.) a faucet repair kit which has various sizes of seats Turn Off Water!!!!!!!! Open lowest sink or faucet outside or inside let drain off pressure. have a pan or something to catch the drips. with the screw driver unscrew handle and take off for minute, unscrew top (sometimes you can stop a drip by tightening this top to push on the packing depending on where it is leaking) of valve with adjustable wrench and take off there will be a packing material around shaft of valve (black, graphite grey) refasten valve handle and open valve all the way (counter clockwise) It should come out after unthreading. On the bottom of valve stem should be a screw holding the rubber valve seat try to unscrew the screw holding the rubber seat if it breaks you take to hardware store and find a replacement take top with you ask for help. Re-install the opposite way Make sure when re-installing to put the packing around stem three or four turns enough for the top to compress it and able to screw back on the valve if you over tighten you won't be able to turn valve back off until you can.

- Q: I have a question about my car. The mechanic told me that my valve body needed to be rebuilt. However I read that the valve body is a sensor that tells the car when to shift gears. Now my car is a semi automatic so I can shift gears myself! I was wondering if someone could tell me whether it was still necessary to rebuild it if I'm going to be shifting gears myself? I just don't want to mess up the valve body even more and eventually have to get a whole new transmission!

- Its an electrically shifted automatic. The valve body is not a sensor it is the valving system that sends fluid to different parts of the transmission to shift gears. The solenoids on the valve body move the valves dependant on what the computer tells it to do. The paddles or shifter you have do not go to the transmission but to the ECU and the ECU decides what to actually do with the transmission. It does not matter if you shift it or let it do it its self if the transmission is going out it needs work or rebuilt, it WILL fail sooner or later and leave you stranded. So you either need to get it rebuilt or get another transmission. If you drive it until it fail you will need another unit, if you fix it now yours might be able to be saved.

- Q: Hello. I am interested in purchasing a Hydroclean Fill Valve for my toilet. Are these good fill valves? Thanks!

- who cares, a toilet fill valve only costs a few bucks. as long as it opens and closes it's a good valve. if it only lasts for a year then it's a piece of junk and you should try another brand. it's not a major decision

- Q: I am 31 and just discovered I have severe Mitral Valve Prolapse (Heart probelm). I probably have to have surgery. I have been healthy all my life and I am a little scared. Anyone had surgery for it? What can I expect??

- costly Madam, i'm a heart professional sending this text for you. desire it enables you. Mitral valve prolapse, often spoke of as MVP, is a basic heart valve illness. The mitral valve is between the left atrium and the left ventricle of the midsection. It has 2 leaflets (flaps) that administration the blood pass. MVP occurs whilst one or the two between the leaflets are enlarged or have extra advantageous tissue. MVP is often innocuous. besides the shown fact that, substantial issues can ensue, alongside with a blood clot in the recommendations and an infection called infective endocarditis related to the mitral valve as nicely as different valves. MVP seems two times as often in women persons as in adult men. that's maximum regularly a hereditary illness. some those with MVP have not have been given any indications. besides the shown fact that, maximum sufferers adventure a speedy or bizarre heartbeat, shortness of breath, easy-headedness, and protracted fatigue. Many sufferers additionally be afflicted by migraines, eating and drowsing issues, an overactive or contaminated thyroid gland, diarrhea, and chilly arms and ft. Emotional rigidity often magnifies the indications. medical doctors usually prescribe prevalent exams and cardio workout for persons who've MVP. sufferers are additionally advised to limit their intake or use of extreme-carbohydrate meals, caffeine, and decongestants. some sufferers would want beta-blockers and specific antiarrhythmic medicine. extra severe circumstances will require surgical operation to repair or replace the valve or to insert an digital regulator, including a pacemaker or defibrillator.

- Q: my Hunter SVC VALVE will not work with my Lawn Genie Valve. Is this becaous the voltage is not matched? Hunter says it operates solenoids at 6-9 v DC // Lawn Genie says it is an 18 v DC solenoid. :-( my original Hunter Valve broke and I replaced it with the Lawn Genie. Should I get a Hunter Valve , or a Lawn Genie Controller at this point/ or is there something I have overlooked?.

- Your Hunter transformer only provides about half the voltage needed to operate the Lawn Genie solenoid. You might find a weaker spring for the LG solenoid, but the long term fix is to stay consistent. Either use all Lawn Genie, all Hunter, all Rain Bird, etc.

Send your message to us

API Cast Steel Check Valve 200 mm in Accordance with ISO17292、API 608、BS 5351、GB/T 12237

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords