Swing Check Valve Wafer Type Double Disc Body Material CF3M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

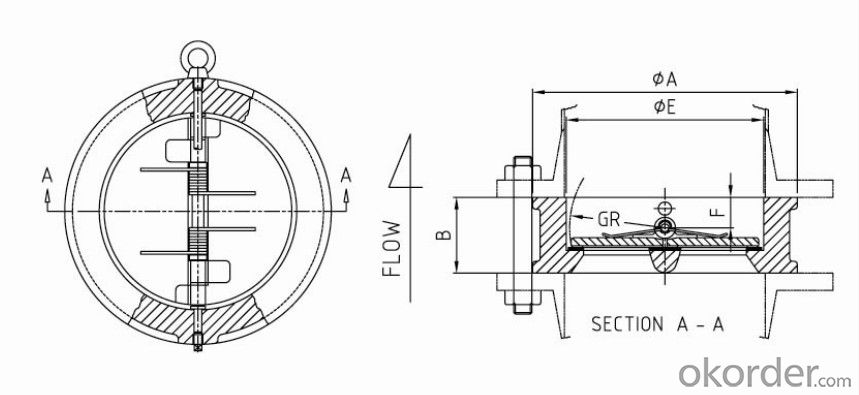

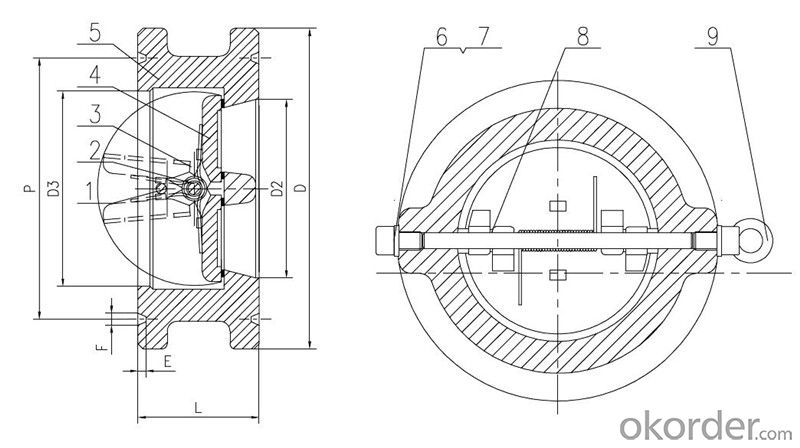

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I have a curtis toledo compressor at my house. While moving it a helper dropped it on its side into the tank and broke off these 2 valves off the very top of the compressor. They had a copper line that ran off both of them and went over to the auto on/off switch, I'm guessing that's what it is. Where can I buy these or at least what are they called?

- They are the unloader valves. Look online for places that sell parts for air compressors.

- Q: I have a 1997 Toyota Corolla. My check engine light has been on. I tried to get my car smogged and it failed. I then got an oil/air filter change and just yesterday I replaced the EGR valve which was the result given after 2 diagnostic tests. The mechanic gave me my car and the check engine light was off, I've only driven about 5miles and the light is back on. I have to pass smog asap to register my vehicle. I plan on calling the mechanic back and telling him the light is on, but could it just be a sensor?

- it could be a sensor ! the EGR code probably showed up because a sensor was interfering with the valve !

- Q: Hi. I am planning to install new kitchen faucet and noticed that there are two shut off valves under the sink. One of them is badly rusted and needs to be replaced. I noticed that it is connected to three pipes (one of which is kitchen faucet). The other is clearly water coming in. What is the third one connected to wall? Also how should I go about replacing this? Anything that I should be careful of? Thank you.Here's picture of shutoff valve.

- Ditto on the picture. It sounds like a valve that supplies water to both the faucet and another appliance. If the line not going to the faucet is copper and measures 3/8 across (OD or outside diameter), likely a dishwasher. If it's 1/4 OD, likely a refrigerator ice maker. More important is what kind of pipe you have coming into the cabinet to the valve. An older house may have galvanized steel, typically nominal 1/2, which measures about 3/4 OD. Newer homes are more likely to have copper, typically nominal 1/2, which measures 5/8 OD. Hopefully, either will come into the cabinet for several inches before meeting the valve. Shut off the water downstairs, then disconnect the two smaller supply lines at the valve. For steel pipe, the valve is threaded onto it. Use two wrenches, one pipe wrench on the pipe itself, tensioned clockwise, then another to unthread the valve counterclockwise. For copper pipe, the valve is typically soldered on or has a compression connector with a fairly wide nut holding onto the pipe. Cleanest removal, with enough copper in the cabinet, is to use a mini tubing cutter and cut the copper right under/behind the valve, freeing the valve. Take the valve to the store and buy a match, preferably a quarter-turn ball valve. One glitch is the possibility that it's an old flare valve - meaning that the two lines you unhooked have flare nuts. If they're copper, I'd plan to slide the flare nuts back a little, cut off the flares at the end of the tubes, and get a new valve with all compression fittings. If the old lines are then too short to make it to the new valve, they can be cut back further, then extended with new copper, or short flexible water supply lines with compression fittings on each end. I'm still leaving out more stuff, but that's enough.

- Q: I was wondering if the pressure relief valve can be vented right under the house or does it have to be ran to the outside of the house. Also is there another method such as a catch pan that I can employ? I live in Washington.

- it should be run outside but most people don,t even use one. you can get a catch pan that fits under the heater but you,ll have to raise your heater up to install it.

- Q: My car had white smoke coming out from the exhaust.After talking to my mechanic, he said that the valve seat is faulty in which i suspected earlier. He also told that my car need to be overhauled. What would a faulty valve seat cause my engine?

- If the valve seats leak it will cause oil to run down the valve stem and either it gets sucked into the intake or it get pushed out the exhaust, depends if both valve stems are leaking. It would be black smoke not white. Your car will produce water in the exhaust system when exhaust goes through the cat converter this may come out as a white smoke but it should not be something you can see if your driving. If it is that much you have a head gasket problem.

- Q: I was diagnosed with Mitral Valve Prolapse when I was 18. I am 23 now and feel like my symptoms have only gotten worse. Sometimes I could just be still and have severe chest pains with slight paralysis in my arms. It's like my body locks up from the pain. Recently I had an episode and I immediately started crying from 3 seconds of severe chest pain. For the past three days I've had this headache in my temples that sends a slight numbness down my jaw. I didn't know if these symptoms were in any way related to my MVP. I'm going to see the doctor today and plan on mentioning it. Does anyone have these same symptoms or an idea of what is wrong?Thank you!

- Although mitral valve prolapse is a lifelong disorder, many people with this condition never have symptoms. When diagnosed, people may be surprised to learn that they have a heart abnormality. When signs and symptoms do occur with mitral valve prolapse, it's typically because blood is leaking backward through the valve (regurgitation). Symptoms can vary widely from one person to another. They tend to be mild, develop gradually and may include: A racing or irregular heartbeat (arrhythmia) Dizziness, lightheadedness Difficulty breathing or shortness of breath, often when lying flat or during physical exertion Fatigue Chest pain that's not associated with a heart attack or coronary artery disease When your heart is working properly, the mitral valve closes during contraction of the left ventricle to prevent blood from flowing back into your heart's upper left chamber (left atrium). But in some people with MVP, the mitral valve malfunctions. In these people, the mitral valve leaflets are abnormal with extra tissue, bulging (prolapsing) like a parachute into their left atrium each time the heart contracts. The bulging may keep the valve from closing tightly. This may not cause problems if only a small amount of blood leaks back into the atrium. When blood leaks backwards through the valve, it's called mitral regurgitation (MR). MR can cause symptoms. Take care always! OIRAM

- Q: Is it hereditary? My dad had a bicuspid valve and we got told it was hereditary but some doctors say it's not, my parents wanted to get me tested in case i had it so we would know in advance but the doctors here refuse to do it (I live in England if that makes a difference) my dad said he would pay to go private if it's hereditary. I know someone who had a bicuspid valve and 3 out of her 4 children inherited it, i know it's pretty harmless until i reach an older age but my parents and i would like to know now, i'm 13 by the way.=]

- it is hereditary sometimes, but sometimes its just a fluke. Im 16 and i have a bicuspid valve and there is no history of this in my family. and yes it will most likely be no problem for you till you get older, if at all most people dont have any problems and will be totally normal, but get it checked just in case because there could be other heart problems caused by it. I have a bicuspid aortic Valve, and aortic stenosis(which is because of the bicuspid valve) which then led to aortic back leak, and then all of those led to be getting an enlarged aorta. Most people do NOT get all these problems, but you never know. Good luck

- Q: My third valve won't move at all. I haven't played my trumpet in a while and I tried to oil it to get it to unstick but it still won't move at all. People say to screw it off but I can only unscrew the little cap at the bottom of the valve where you push in, not the white button at the top. Help please! Thank you so much! =]

- i got here across that Dennis Wick valve oil is a procedures more advantageous ideal to any that I easily have used. you'll locate it on Amazon. If cleansing with dish cleansing soap and heat water would not artwork, alongside with the Dennis Wick oil, I recommend that you're taking it to a restoration shop. be careful at the same time as cleansing now to not get any cork or felt moist. only dip the truly valve section into the water.

- Q: Hi, this is a part 2 question to the one I posted last night. After turning the water shut off valve on my toilet back on, it didnt start to hammer till about 1 min pasted. When the hammering is happening I look in the toilet tank and see air bubbles coming out of the base of the fill valve and the water coming out of the fill tube isn't smooth and flowing its kinda step wise/ in intervals. I forgot to mention that I live in an apartment, does this affect anything?My official question is, is this an air bubble problem or is it a rubber gasket/ rubber seat problem?This is a new building only about 2 yrs old, so parts can't be that bad right?

- First check for a kinked or twisted supply connector hose. You may also have a piece of rubber gasket/washer debris stuck in the valve body (seat washer) or in the fill valve itself (from the connector compression washer). Shut off the water supply at the angle stop and disconnect the supply hose from the fill valve nipple under the toilet tank. Get a bucket and put the end of the supply connector hose/tube into the bucket and open the supply valve again. If it still hammers when unrestricted like this, the obstruction is in the anglestop valve body. The water pressure may force it out, but if it doesn't, you'll have to shut off your main water supply to clean the stop or replace it. If it doesn't hammer when unrestricted, the problem is now in the new fill valve, and is probably a deteriorated piece of the compression washer in your old supply connector hose or tube that has been pushed into the fill valve. Since it's a Fluidmaster, you can disassemble the head of the valve and remove any visible obstruction or just replace the top part.

- Q: my Hunter SVC VALVE will not work with my Lawn Genie Valve. Is this becaous the voltage is not matched? Hunter says it operates solenoids at 6-9 v DC // Lawn Genie says it is an 18 v DC solenoid. :-( my original Hunter Valve broke and I replaced it with the Lawn Genie. Should I get a Hunter Valve , or a Lawn Genie Controller at this point/ or is there something I have overlooked?.

- Your Hunter transformer only provides about half the voltage needed to operate the Lawn Genie solenoid. You might find a weaker spring for the LG solenoid, but the long term fix is to stay consistent. Either use all Lawn Genie, all Hunter, all Rain Bird, etc.

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material CF3M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords