Swing Check Valve Wafer Type Double Disc Body Material CF8M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

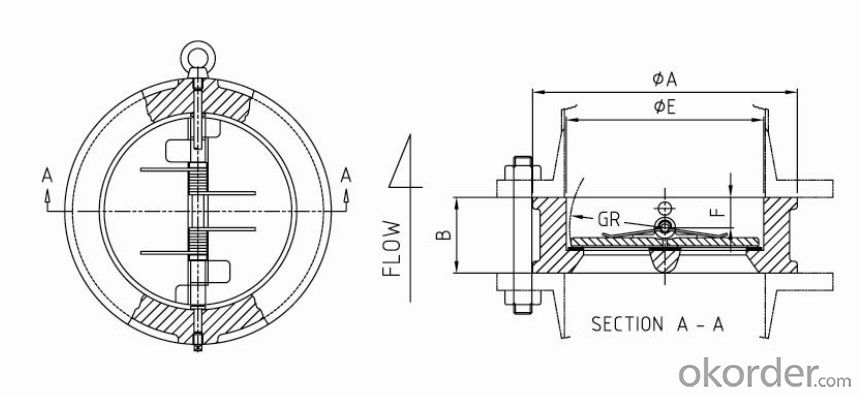

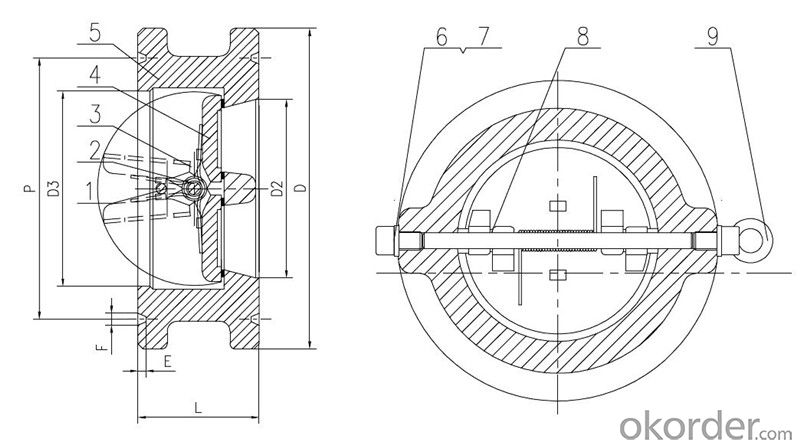

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customiz |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: My friend had heart surgery and it was pretty serious. She got a new heart. Days later they checked her and discovered that she bursted a heart valve. The doctors say it's one she can live without. That really concerns me. The valves connect directly to the heart. Please help.. Will she be ok if she doesn't get it replaced?

- If she has a ruptured heart valve it needs repair or replacement. The valves serve a critical role in maintaining normal flow of blood through the heart. Without the valves blood will backflow and cause buildup and many problems. Maybe she is stable and can wait for surgery at a later date? I'm not aware of a situation where you can live with a ruptured valve. I hope she is in good care.

- Q: I have three zone valves, two out of the three don't ignite the gas. Once I turn up the thermostat I see the lever on the zone valves move but no gas ignition. Only one of three works fine. Any leads? Thanks!

- the zone valve will turn on the pump. if the water temp is high enough, the gas wont turn on. check the aqua stat to see the temp setting

- Q: I was told on Tuesday that i have mitral valve prolapse and that i inherited it and that i will be fine. Well i take toporol xl 50 mg because the mitral valve prolapse makes my heart beat fast. For the past week i have noticed that my chest/lungs get tight, kind of like i have congestion in my chest, it comes and goes and sometimes its really bad and sometimes i can tolerate it. Is this normal for someone with the mitral valve condition. My cardiologist didn't go into details about the symptoms and i'm wondering if i should go see another doctor. I do have a sniffly nose and was wondering if this could be symptoms of a cold or something else. Any one out their with my condition having the same problems??? If so what is it???

- I have mitral valve prolapse and have lived with it for quite a while. I take no medications for it all. It's more common in females than males, and is usually not a cause of major concern. If your symptoms are worse than before you were diagnosed than you should consult your MD . Some people with mitral valve prolapse require surgery but that is rather uncommon. As with any heart issues there are degrees of involvement. Ask your MD to order an Echo-Cardiogram. It is a non-invasive test, painless and simple. That with whatever other test your MD may suggest should determine how bad the prolapse is. See a (Cardiologist ) is my recommendation. The symptoms that you are having are quite common with this condition, all except the sniffles.

- Q: i wanted to know what is the actual difference between check valve (non return valve) and globe valve?

- Check valves are designed to prevent back flow. A globe valve is used when the ability to throttle and control the flow is desired. The globe valve can be positioned at anywhere from 1% to 100% flow. This allows for very precise control over how much liquid will be allowed to flow through the valve. There is another type of valve called a gate valve. The gate valve can not be positioned with such precision as the globe valve and it is used when flow rate is not as important.

- Q: Movers messed up the valve so hose won't screw in w/o leaking

- Buy a new valve at an appliance parts outlet. Make sure it's the right one. Many times they will come with instructions. Unplug the unit. Shut off the water and remove the hoses. Remove the back panel to access the valve. Remove the old broke valve and replace it with the new one. Replace the panel. Attach the hoses and turn on the water. Check for leaks. Plug in the unit and give it a test. Try all the temperature settings. Congratulations. You are now a professional..

- Q: We are using safety valves of gas and steam for detergent slurries. Why they do not function?

- I suggest that you rethink that application. Even if the valve does function it might not pass enough slurry quickly enough to relieve the pressure overload.

- Q: the pressure relief valve on the top of the tank needs replaced

- Gas fired? Place thermostat to pilot to keep burner from coming on while you work. Turn off cold water supply to Hot Water heater. Open all the Hot water faucets in the house. Get a Pipe wrench and some pipe dope. and of course the new relief valve, place some towels under the relief valve as some water will leak out. Put pipe dope on the new relief valve threads, remove old relief valve using steady pressure, immediately put in new properly pipe doped relief valve, screw in hand tight, then use pipe wrench until it is set. Don't over tighten. Dry off area around new valve so you can more easily detect leaks. Reopen supply water to HW heater, let faucets run until no more air comes out, then shut faucets. Put regulator back on. Done.

- Q: this question is related to Ball valves, In actuated valve for the selection of actuator we need differential pressure across the valve so I wanted to know that what is meant by differential pressure?

- Differential Pressure Definition

- Q: My washing machine had hot and cold water, but was leaking. I changed the inlet valve which stopped the leak, but now I have no hot water. When I put the setting on warm, the cold water runs for a bit. Then stops and no hot water comes. Any help?

- I suspect the leaking valve that was replaced was your washer's solenoid valve. Did you remember to turn the hot water supply valve on after you finished? That is the valve, next to the cold water supply valve, on/at the wall behind the washer. There are rubber hoses coming from those valves to the solenoid valves on your washer. If you forgot to turn it back on after replacing the leaking valve you'll get no water. If you turn off both the hot and cold supply valves on the wall you should be able to remove the rubber hoses right where they connect to the machine and check the water flow by directing them into a bucket or pan while you open the supply vales. If you have good pressure and flow make sure there is no debris clogging the screen, just inside there the hose connects to your machine. These can get blocked where the water won't pass or runs very slow. Sometimes it pays to check the simplest causes first. Good Luck. SS.

- Q: I have a hot water oil burner. I need step by instructions on how to replace the pressure relief valve.Do you know?Please help me.

- First off shut it down and let it cool off turn off the water source and the power to the unit. You will need either a large adjustable wrench or a monkey wrench to remove the valve if there is a drain pipe connected remove it first. Check the temp stamped on the old one and make sure the new one is for the same temp. you will need Teflon tape wrap around the threads several times to form a good seal.tighten and put the valve at the same angle it was before. Turn everything on and run unit to check for leaks. Good luck

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material CF8M

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords