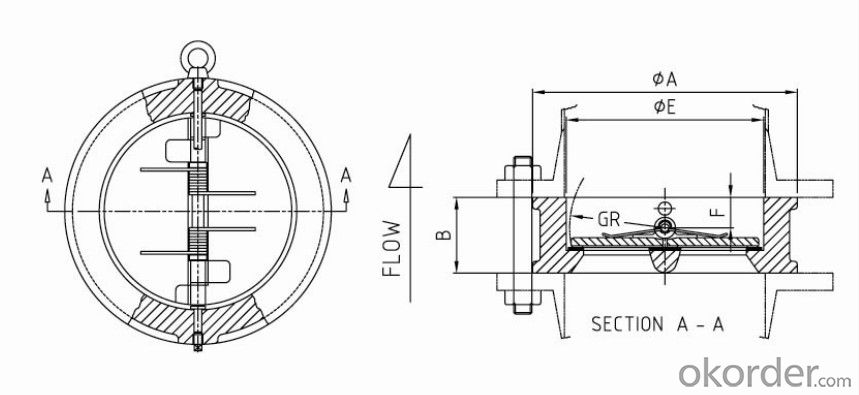

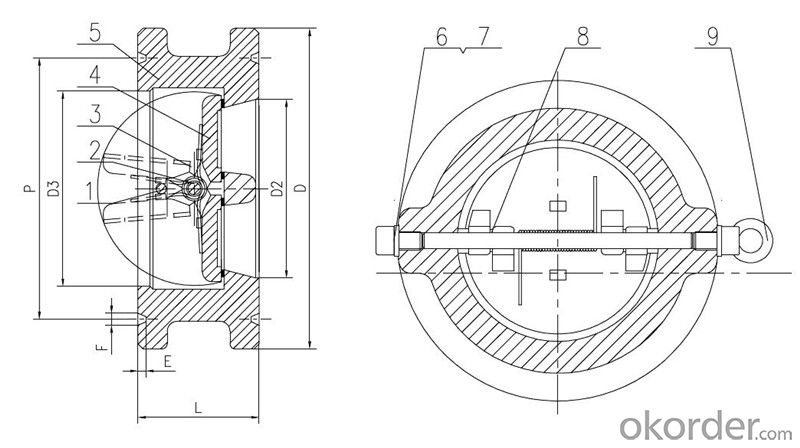

Swing Check Valve Wafer Type Double Disc DN 450 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: My electric water heater relief valve keeps opening 30 min after turning it on.I turned it down to 90F and 30 min later overflow again.when power is off no leak with the water on uld the valve be opening because of over heating?I know it does'nt leak with cold running through it.

- Sometimes I find that the relief valve is not working correctly and needs to be replaced. They tend to get a buildup of minerals from the water that interferes with proper function.

- Q: non-return valves

- ..?..non-return valves..? I will assume that your 'non-return valves', are what is also known as check valves. Check valves allows flow in one direction only. These are used wherever you need to prevent backflow into the system, or to maintain a charged circuit with fluid, until you choose to unload(depressurize ) it. Now, why are they used in discharged lines of salt water, basically to prevent backflow....reason not known, here , requires usage info.

- Q: my pcv valve tube is broken in half I replaced it with a rubber hose does it have to be whole

- pcv valve does not hepl transmission inany way it stands for positive crackshaft ventilation pcv valve is for emissions only it does nothing for transmission should be replaced on most cars every 48000 km, i would'nt worry about a pcv valve..

- Q: I have mitral valve prolapse and I don't get why only some people get chest pains? and what causes people to get chest pains with M.V.P (mitral valve prolapse), like me. PLEASE HELP!!!!!!!

- With MVP, your mitral valve is smaller due to extra tissue. This makes it a little bit harder for blood pumping through the valve to get through, which can often times cause an aching pain. As far as I've seen, this is not life-threatening and the pain can be treated with over-the-counter painkillers. Imagine you kink your garden hose while it is running. The water can't get through the hose and the pressure builds up. When you unkink the hose, the water flows freely. Your mitral valve has a permanent partial kink or blockage. The blood behind that partial kink can get blocked up and cause pressure in your chest. Be sure to get regular check-ups with your doctor, just to be sure your MVP is stable. Your doctor will also be able to suggest some pain remedies.

- Q: Just wanted to know what the significance of the number of valves is?I know that theres valves for intake and exhaust if i'm correct.if there is four i'm guessing its 1 for air and 1 for fuel if its fuel injected. and 2 for exhaust?are there bikes with 3 valves or more than 4 valves and why?and a basic carburated 2 stroke just has an intake from the carb side and then an exhaust.please give me more info and let me know if i'm correct or not.

- As goobersmooch says, your guess regarding 4 valves is wrong. On a 4-valve engine (i.e. that means 4 valves per cyclinder) there are two exhaust and two inlet valves. I can't remember offhand if there are bikes with 3 valves, but there are definitely cars with 3 valves. They are usually one inlet, two exhaust, because the exhaust valves get hotter (having to deal with hot burned gases) and two valves give a better surface-to-volume ratio, thus aiding with keeping them cool. I'm fairly sure there are bikes with 5 valves per cylinder, but I'm danmed if I can remember what they are. Why? Same principle applies - more valves in a given space means a better area for the gases/vapours to flow over = more efficiency. But eventually the ol' cost/benefit ratio catches up. It's harder to make a valve train to open 5 valves than it is to make one to open 4,3, or 2. All engines have their intakes on the carburettor side, whether 2-stroke or 4. Or, more acurately, their carbs are on the intake side. 2-stroke valves, if they have any, are completely different to 4-stroke, and they are on the intake side only. A 2-stroke engine doesn't necessarily need to have valves.

- Q: I have a 98 Mitsubishi Mirage, seems there is a valve cover oil leak, i know this can be easily fixed by replacing the gasket.. but how will i know if the leak isn't from the valve cover gasket . Is the cylinder head gasket a major issue also .. if its not really the valve cover thats producing the oil leak should i not worry and just replace the valve cover gasket .?

- Sounds like you should clean your engine, then take a look to see where the leak is. Have you tried tightening the valve cover bolts?.

- Q: My sump pump shut-off valve is very noisey. I wrapped insulation around it, but it still clunks. The clunk can keep me awake.

- Silent Sump Pump

- Q: need a different pump for? Is this some improvement on the old valve?

- There are schrader valves which are bigger diameter and are used also for automotive tires. They have a spring-loaded center pin that gets pushed down and opened when a inflating head is used. The spring is what keeps the air in the tube. The presta valve is the skinnier one. It does not rely on a spring to keep the valve close. The air pressure inside the tube keeps the valve closed. Generally, less expensive bikes use schraders while better bikes use prestas. All decent pumps have pump heads that accomodate both types. Either it is done by manually reversing the inside of the head assembly to change between presta and schrader or the head automatically adjusts or you use the appropriate one when the head has holes for both.

- Q: why can't i just use solenoid valves hooked to a small bank of relays(using relay logic to control operation) connected to thermostats to control a multi zone boiler system? it would work, but can i do it, why must i use expensive zone valves?

- Its just an educated guess but I would say it would cause system shock if a valve just snapped shut as against closing gently. Assuming the system was shutting down as a zone valve shuts the control switch opens and turns off the plant whilst the valve is still partly open. With a solenoid unless you fit a timer to pre shut off the plant then shut off the solenoid you would probably cause some plant damage. Also by the time you have wired all that lot up you may as well do the job with a zone valve.

- Q: We had a sprinkler zone that did not send much water to sprinkler heads. Checked the spring on the solenoid. We took off the top of the valve and rinsed gasket and parts below – put back together. The zone then worked. However I then noticed that the valve that does not shut off completely – water meter shows usage. I turn off water as it comes from the house.We then replaced the solenoid, the zone would not turn on. When back to the old solenoid. I switched wires at the timer and valve, it started, but when the cycle was through there still was water going through the system. Put wires back to their original locations.Space is crowded and looks tricky to replace valve. Would like advice on that for next year. However my main concern is when we shut down for the winter. We manually run each of the 8 stations and blow out the water. Will the bad valve cause a problem?

- we had the same problem last week. the valve was leaking allowing water to seep through. luckily it is a current valve and all the man did was replace the top part and that solved the problem. 75 bucks and he also checked out the entire system for proper operation.

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 450 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords