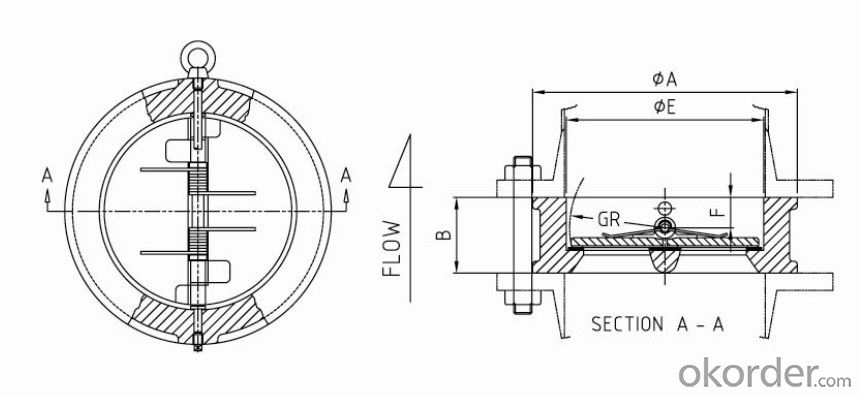

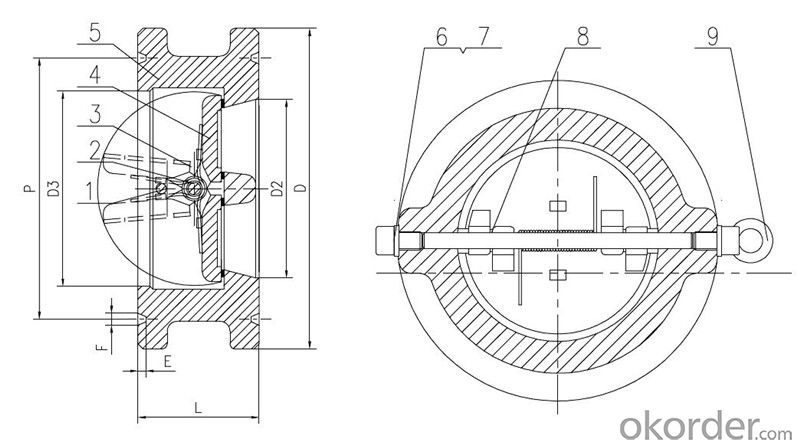

Swing Check Valve Wafer Type Double Disc DN 600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: what does mild sclerosis of aortic valve means? Why does it happens and what is its curethanks

- This is a routine, well established procedure. The incidence of major complications are less than 4%. There are two kinds of artificial Heart Valves. One is mechanical, and the other is tissue valve. The mechanical valve requires the person to be on life long anti-coagulation therapy. This also requires periodic check on the persons pro thrombin time. Based on this, the anti-coaglation dose will be adjusted. The problem with anti-coagulation is that it may lead to bleeding complications. The tissue valve is made from the tissues of a bovine or porcine heart. The tissue is denatured to ensure that the valve is not rejected as a foreign tissue. (This is not a problem with mechanical valves.) Being made of tissue, these valves do not allow clots to form, which means that anti-coagulation after a short initial period is not required. This is a major advantage, especially for women, who may have some earlier bleeding problems. Then why are mechanical valves used at all? Being made from non-living denatured tissue, tissue valves cannot repair themselves. They also tend to get calcified in younger people with more calcium activity. They also have a shorter life than mechanical valves. Surgeons tend to favour mechanical valves for younger people (whose life expectancy is higher), and the tissue valve for the older, as such people may already have some bleeding problems, the valve's durability is not critical and the patient has lower calcium activity. These are general considerations. Only a surgeon armed with the full test results, and a knowledge of the patient history, who can advise the patient on what is the best option in each case. To reiterate, AVR (Aortic Valve Replacement, not my initials) is a routine procedure and recovery tends to be uneventful. Wish you all the best, and as uneventful a recovery as possible.

- Q: Alright. The engine is a 7mgte. The clearances for the skims in the intake side is 0.20mm and the exh side is 0.25mm. What happens if i mixed the shims?

- You can check the clearance with a feeler gauge of the correct thickness.If the gap is too big it will tick,idle will be rough,and throttle response will suffer.

- Q: I am trying to repalce the water turnoof valve under my sink but the valve just keeps turning and no progress is made to get it off so I can put on a new one. I am turning it clockwise but it just keeps turning. Can someone please tell me how to get this off? I do not want to have to call a plumber for something that I might be able to fix myself.Thanks.Sandy

- basically component to the diverter valve is broken, besides the undeniable fact that, it extremely is terrific to replace to total diverter stem. If their are 3 handles, you are able to do away with the middle one devoid of turning the water off. Then convey total stem with you to the ironmongery shop. There are quite some video clips on youtube and different ironmongery shop factors of interest in case you like help. good success.

- Q: When and why do you need to get a valve job? My car has 85k miles on it. What is the difference between a valve-job and valve-adjustment? what would the increase in power be on mine? 3800 series 2 engine, assuming it is just a little old, no major problems. 5-10hp?

- MOST modern engines have hydraulic lifters, which pretty much eliminates the need to have any periodic valve adjustments. You can take stock heads to a shop and put two grand into them and make better flow and bigger valves and more power, or actually buy a set of performance heads for less and make more power. the only time your valves would need to be set is when putting together a new engine, or taking apart the one you have and replacing say a head gasket or something. (in which case you would have a shop go through the heads and make sure they are up to factory specs. If your engine is running fine, and you have kept the oil clean and the motor in good tune, follow the recommended maintenance intervals in your owners manual. a valve adjustment is not going to give you horsepower.

- Q: How much will it cost to fix 5 broken gas valves out of 6 from my truck it's a Chevy s10 99'I live in North Carolina

- ...Gas Valves???....WTF....

- Q: where in the engine is the heater control valve located on a 2001 toyota corolla

- standing okorder / sign up and post in the 8th gen corolla forum. great ppl. been a member for years.

- Q: behind the valve cover of the #1 and #2 cylinder there are 2 intake and 2 exhaust valves I need know (cylinder #1) which is the intake and which is the exhaust. thank you in advance.

- 1. Intake valves are usually larger than exhaust valves 2. Exhaust valves are on the same side as the exhaust manifold

- Q: I got a '99 bmw 740il that is leaking and burning oil. It shoots smoke out the exhaust when i first start it from burning oil. And the car misfires when idling, i did a tune up and the spark plugs were soaked in oil causing the tune up not to help anything for long cause it was missfiring the next day. Does this sound like the valve stem seals? I bought new valve cover gaskets and grommets and im gonna replace those this weekend, im hoping that will help. Comments please

- Bad okorder /

- Q: I have mitral valve prolapse. Just recently Ive been getting chest pains more often * few times a day* and the panic and anxiety have gotten worse. I had a pain last night that lasted about 10 minutes and it was very uncomfortable.I know mitral valve prolapse is a condition that usually not a threat. But can it get worse over time with some people?My doctor already knows I have it but should I go back to have more tests done?Im kinda scared because my symptoms are getting to be more than what they were.Any advice?

- It's not clear whether or not your symptoms are pathological and you are anxious and worrying because you are having symptoms or you are having panic attacks/anxiety episodes and the symptoms you are having are a result of this. It's often a vicious circle, there may be nothing wrong. As you have been told, MVP is a fairly common finding and generally does not cause any problems. MVP is often over-diagnosed, especially in young women- GPs are terrible for this. This happens because some Doctors have incomplete understanding of normal valve anatomy and ECG appearances. Various symptoms are often attributed to MVP, such as atypical chest pain, palpitations, syncope and anxiety. These were sometimes termed mitral valve prolapse syndrome. However, data from the Framingham study and others does not support a link between these symptoms and MVP. Please bear this in mind because some misinformed Drs and Nurses may try to tell you otherwise. The problem only comes with MVP is if one develops severe mitral regurgitation. IF there is severe regurgitation (which I seriously doubt), the most likely symptoms you would experience would be breathessness, dizziness or tiredness. Chest pains (angina) can occur if there is reduced blood flow to the coronary arteries or if not enough blood gets to the thickened ventricle. Best advise here is for you to pop along to your GP so he can do an ECG and possibly an Echo, this is more to set your mind at rest though. In absence of other symptoms, the most likely explanation for your symptoms is musculoskeletal pain.

- Q: why do new motorcycles need to get their valves shimed alot? can someone explain how the whole valve adjusting thing works? why do some engine types require more attention? i have owned thumpers my whole life and never really thought about it. i was looking at this like cheap beater bike (hyosung gt250 v twin) and i read the valves need to be checked like 3 times in a short span, wtf??

- Motorcycle Valve Adjustment

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords