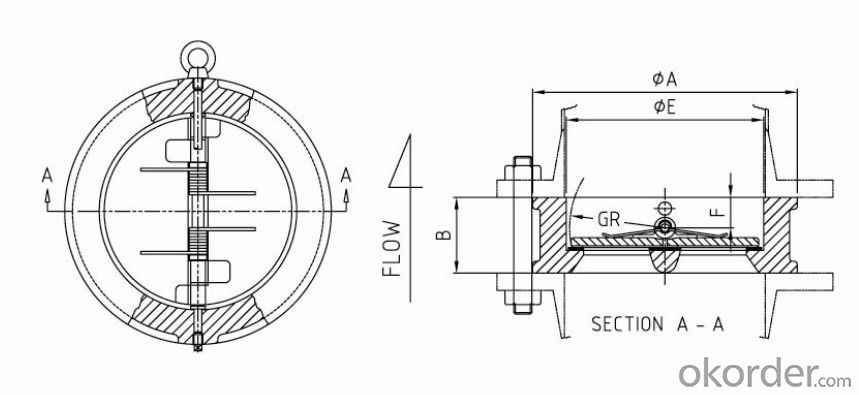

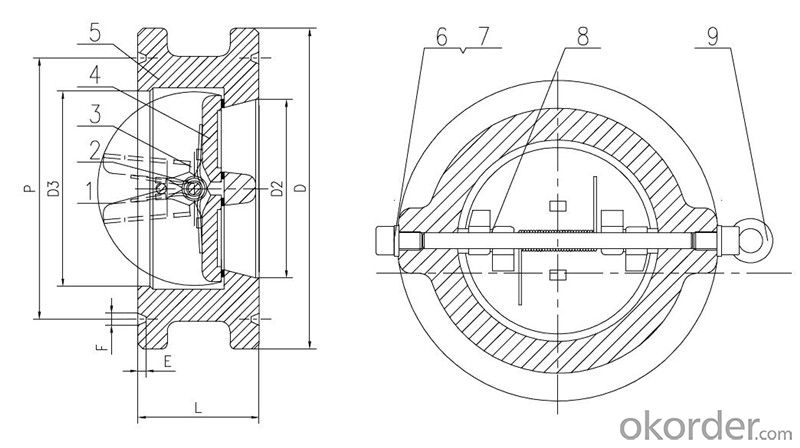

Swing Check Valve Wafer Type Double Disc DN 200 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: anyone know where this switch or whatever you want to call it is located. the car was in accident. so it wont start but cranks. so i wanted to know where the shut off valve is located for the fuel. thanks.

- 2007 does not have a shut off valve. Sounds as if some one has used a non programed key Nissan Imobilizer has detected the aftermarket non programed or key with chip embedded in the key has failed. After 4 attempts the car turns on lock mode and it is tow truck time. Gather up all the keys you have they all have to be reprogramed. And it is a good time to have two complete sets of keys and remotes money allowing of course. Only computerized lock smiths and Nissan dealerships can introduce keys. Is there a red light that looks like a car with a key lighting up when you attempt to start the car?

- Q: I opened the OPD valve on the BBQ propane tank and propane spray out, I have heard that propane should come out only when it is hooked. Is there something wrong with the propane tank?

- extremely tough stuff seek onto yahoo that will will help

- Q: Im trying to replace the egr valve on a 97 lincoln continental. I need to find out what size wrench I need, to get the nut off. Do you know?

- I am assuming you want to replace the EGR valve because you are getting an insufficient EGR flow trouble code. Before you replace a perfectly good valve with an inferior aftermarket part that will likely fix nothing, a little more diagnosis is in order. If you have access to a scan tool and a vacuum gauge, perform a KOER (key on engine running) test on the engine with the vacuum gauge connected to the hose to the EGR valve. When self-test reaches the EGR test, look for the vacuum guage to move during the self test. If it moves, the vacuum source and EGR solenoid are good. If not, trace the vacuum harness for leaks. Without the scanner and vacuum gauge, find a length of hose and suck on the hose, or connect to other vacuum source to test the valve. You are looking for an RPM drop at idle when you open the valve in this way. I suspect your problem is a passageway clogged with carbon. Remove the valve and throttle body to access the clogged areas and manually decarbonize. This is the most common reason for an insufficient EGR flow on a Lincoln, along with a faulty DPFE sensor or related hoses. My money is on the clogged passages or the bad DPFE sensor.

- Q: We have a 2005 GMC Sierra 1/2 ton truck that has a check engine light on. The dealer checked the code and he told us we need a new Evap Vent Valve and clamp. The cost is over 500.00 with labor being most of the cost. Is this diffcult to change out? Im a very mechanical person. Also he said it would be ok to drive for now but could cause problems down the road. ????like what?My wife is getting ready to take a trip in it, should it be ok for awhile? Dont have 500+ to spend on it now.

- This Site Might Help You. RE: Evap vent valve? We have a 2005 GMC Sierra 1/2 ton truck that has a check engine light on. The dealer checked the code and he told us we need a new Evap Vent Valve and clamp. The cost is over 500.00 with labor being most of the cost. Is this diffcult to change out? Im a very mechanical person. Also he said it would...

- Q: I was wondering if the pressure relief valve can be vented right under the house or does it have to be ran to the outside of the house. Also is there another method such as a catch pan that I can employ? I live in Washington.

- it should be run outside but most people don,t even use one. you can get a catch pan that fits under the heater but you,ll have to raise your heater up to install it.

- Q: Also please tell me why globe valves are preffered for Landing valves in wet risers in firefighting and gate valves in dryrisers..

- A gate valve is like a garage door. A globe, typically called a ball valve, is round with a hollow center and two (open / close), three (open / close in multiple directions) or sometimes four (open / close in multiple directions where one direction is always flowing when valve is open) side openings.

- Q: my dad is going to go under heart valve replacement what are the chances of him surviving he is 58 years old and has copd

- It depends a lot on which valve and why it's being replaced, but unless the COPD is very bad, the average chance that a 58yo man who does not have any other major medical problems will survive single-valve replacement surgery is better than 98% if the surgery is done by an experienced surgeon at a good hospital. The COPD will very likely mean that his post-operative recovery will be prolonged and difficult, but he should do fine.

- Q: I'm thinking about getting a Cold air intake along with a Bypass Valve to prevent Water Indigestion on my Toyota Corolla 07. I was wondering if Bypass Valves actually work and can someone explain to me the physics around it???( How bypass valves work)

- This Site Might Help You. RE: Cold Air intake + Bypass Valve. ? I'm thinking about getting a Cold air intake along with a Bypass Valve to prevent Water Indigestion on my Toyota Corolla 07. I was wondering if Bypass Valves actually work and can someone explain to me the physics around it??( How bypass valves work)

- Q: I have a T4-T10 and L5-S1 spinal injury and I recently found out that my tricuspid and my mitral valves leak. I have never had heart problems before I got the spinal injury. Do you think the valve leaks could have been from the trauma when I received the spinal injury?

- Maybe but usually MVP doesnt give people much problems and if it does usually sudden

- Q: I've just been told that I need to replace the valve cover gasket on my 97 Volvo 850.....to the tune of $650.00 .....ouch.....is it that difficult to fix?......can you use the red gasket sealant? is there a difference between the head gasket and the valve cover gasket.......yeah I know there probably is.......but when I look on line all i can find is head gaskets......no valve cover gaskets........which scares me into thinking they are the same thing.....i'm hopeing i'm wrong......if its the valve cover gasket it looks like it would be right on top of the engine and fairly accessable.......or am I wrong......sure would like to save the $650 if it is something i can do myself!!!!

- Valve Cover Gasket is a tuff thing to fix alone. I would say, take it to the shop and pay the $650.00- look at it like this, at least you will have a garentee if anything goes wrong you take that bad boy back and have them hook it up the right way! Best of Luck!

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 200 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords