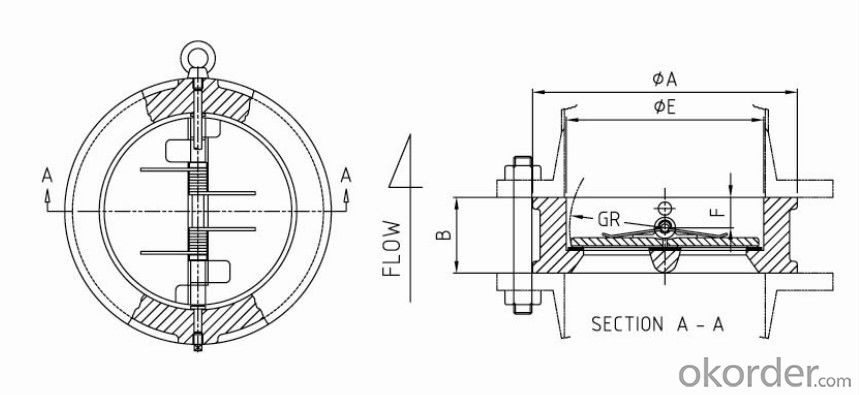

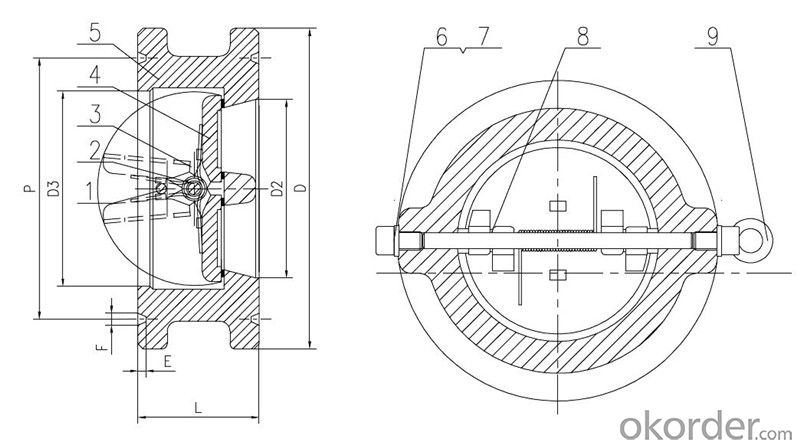

Swing Check Valve Wafer Type Double Disc DN 250 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: We have an oil steam system. There are Dole valves - 1A on each of the radiators. We bought new ones. They don't seem to be working. They look like a bullet shape with a screw in (on the side of the bullet) to the radiator. On the top of the bullet is a slit with numbers 1-10 on a dial. A picture we saw on the web showed a plastic piece of tubing in the screw part which looks like it goes into the radiator. If we remove the valve, the radiator gets hot with steam coming out of the hole. With the new valve on, the radiator barely gets warm. We're in Piscataway, NJ 08854. H-E-L-P.

- First off these are vents , the valves are at the bottom of the radiator where the pipes come in. Sounds like the vents are either closed or broken. Try turning the adjustment screw if that doesn't work I recomend replacing the with vent from a company called ventrite the valve you are looking for is a vent rite #1. These are adjustable vents used to balance the heat throughout your unit the dial at the bottom is labeled 1-8 start with all of them on 8. Now when the radiators heat up if you find some are getting hotter faster turn those down a notch and check again in a day or so.

- Q: 1998 Ford Crown Victoria LX 4.6L Use 89 Octane BP, Shell, Chevron gas. When the engine is under stress(acceleration or going up incline) the engine sounds like the valves are chattering. I can increase the rpm's and the chattering goes away. Had the same problem with 95 Thunderbird 4.6 and have heard other ford cars going down the road with this problem. Air leak? Don't really want to use higher octane due to gas prices and possible engine damage. Also, in the thunderbird, i used a bottle of octane boost and the next day a valve spring broke. Was the octane boost a possible cause?

- it is not valve chatter, it is called Pinging, it is a fairly common problem, what it is caused by is hot spots in the engine, or by overly advanced spark timing, i would check your base timing, perhaps even back it off a degree or two, i would also run a bottle of marvel mystery oil, or gm top engine cleaner through a vacuum line to burn out the crud that has built up, the sum total of these repairs: about 15 bucks, the savings: your engine! as for your t-bird, it was the pinging that broke the valve spring, not the tank of hi octane. hope this helps

- Q: Ok, I recent rebuilt a set of vortec heads, but the valves I got are a bit longer than stock, I believe .1 competition products pn I2552P. I also installed howards cam 98214 springs with 10° locks and retainers, the locks are +.035. I was just wondering if I would have enough spring pressure.

- You need to measure your installed height. No guessing here at all. Measure to be sure. If you don't have a valve spring micometer, you can use a std dail caliper's outside jaws. Remove spring, put retainer on, put 2 locks in, and pull up on retainer till it seats in lock groove. Now measure from spring seat on heads to bottom of retainer.. If you have to then you can measure to top of retainer and then measure thickness of retainer and take that off of your total. You have to know the installed height to figure spring pressure change. The 98214 springs has a rate of 411.. That 411 # per 1 inch and rated installed height is 1.700 So you take the amount of change from the 1.700 and X it by the rate of 411 and that's your total pressure change.. Then take or add that to your rated pressure (which is 115 #) and that gives you your new spring pressure So lets just say installed height is now 1.750 So .050 x 411 = 20.55 #, 115 - 20.55 = 94.45 # total seat pressure Now you need to list the cam your running, diff lift needs diff amount of spring pressure ***EDIT*** Thats a .465 lift cam. If your not winging RPMs past 5,000 then you can get away with a 80 # seat pressure spring, 6K rpm you would need about 5-8 # more seat pressure

- Q: I have a 2006 saturn vue that has a valve tap in the engine. The car has about 100k miles on it now. I'm the original owner of the car, and I've had the problem with the valve tap since about 50k miles, and even when taking it to saturn dealerships, I was told it was nothing and the car was fine. Now that I know what it is (I took it to another mechanic that was a friend who went over it with a 'fine tooth comb') I ahve done research and know what can go wrong a little too late :(So my question: My car only makes the tapping sound for about 5 or so minutes when i turn the car on, then it goes away and you can't hear it anymore, is this usual for a valve tap?

- Yes, it's quite usual. You're more likely to hear the valve tap when you start up the engine from cold. This is because as the engine warms up, expansion of the metal components slightly reduces the clearances and so the sound tap goes away. I'd also agree that you should keep an eye on the engine oil level. If the oil level is a bit low then the tap can also be accentuated.

- Q: can anyone tell me the difference between Pressure Safety valveTemperature Safety ValvePressure Relief Valveused in a process industry

- Doleful is an adjective which means that it describes a noun. Similar words include: dreary, forlorn gloomy, grieving, lamentable, melancholy, mournful, pitiful, plaintive, sad, sorrowful. It was a very doleful day for Mary when she had to leave her friend behind. Lament is a verb. It means to grieve or to bemoan the loss of something. Frank lamented the death of his beloved cat. Woe is a noun. Other words meaning the same thing are misfortune, sorrow, suffering, grief. misery. Woe to the person who breaks his promise to me. Their woes became unbearable to handle.

- Q: I have a 98 Mitsubishi Mirage, seems there is a valve cover oil leak, i know this can be easily fixed by replacing the gasket.. but how will i know if the leak isn't from the valve cover gasket . Is the cylinder head gasket a major issue also .. if its not really the valve cover thats producing the oil leak should i not worry and just replace the valve cover gasket .?

- Valve cover leaks are typically characterized by what you're experiencing: oil oozing out from the cover/cylinder head mating surfaces. If this were your cylinder head gasket, then you'd be experiencing some problems with how the engine runs ...very unlikely it would cause oil to leak from the valve cover. *Do not* simply wrench down on the bolts holding the valve cover; all you will do is crush the gasket and create a bigger leak. Two things you need to do: replace the valve cover gasket and make sure your PVC or crankcase vent system is not blocked. Swapping the gasket is pretty obvious ...they get old and dry out and leak. Checking/cleaning the crankcase vent system keeps compression blow-by gases (a normal thing in engines) from pressurizing the crankcase and forcing oil to seep out in places it shouldn't. A healthy, properly working crankcase vent system helps prevent this.

- Q: pls. tell me the differnce between isolation and block valves and also where it to be used .

- An okorder /. There's numerous systems that use isolation valves. Let's say you want to make some ice cream, you open the isolation valve to let the milk flow into the mixer, then open the valve to let in the cream. Depending on the valve type, you could then open it to allow in the vanilla, sugar, egg, etc. All with the same valve. It just keeps the ingredients from coming in contact . A block valve is used to shut off a supply, so you can perform maintenance, or just stop the flow.

- Q: need a different pump for? Is this some improvement on the old valve?

- There are schrader valves which are bigger diameter and are used also for automotive tires. They have a spring-loaded center pin that gets pushed down and opened when a inflating head is used. The spring is what keeps the air in the tube. The presta valve is the skinnier one. It does not rely on a spring to keep the valve close. The air pressure inside the tube keeps the valve closed. Generally, less expensive bikes use schraders while better bikes use prestas. All decent pumps have pump heads that accomodate both types. Either it is done by manually reversing the inside of the head assembly to change between presta and schrader or the head automatically adjusts or you use the appropriate one when the head has holes for both.

- Q: Well I had a Anginogram that said I have Mitral Valve Stenosis with the LVEDP was Moderately Elevated and My Right Ventricular Moderately Elevated and My Right Atruim is Moderately Elevated what do all this mean I see my cardiologists in two weeks to go over things. Oh yes they don't say how much the Mitral Valve is narrow.

- Mitral stenosis (MS) is narrowing of the mitral orifice impeding blood flow from the left atrium to the left ventricle. The (almost) invariable cause is rheumatic fever. Common complications are pulmonary hypertension, atrial fibrillation, and thromboembolism. Symptoms are those of heart failure; signs include an opening snap and a diastolic murmur. Diagnosis is by physical examination and echocardiography. Prognosis is good. Medical treatment includes diuretics, β-blockers or rate-limiting Ca channel blockers, and anticoagulants; effective treatment for more severe disease consists of balloon valvotomy, surgical commissurotomy, or valve replacement. The normal area of the mitral valve orifice is about 4 to 6 cm2. Under normal conditions, a normal mitral valve will not impede the flow of blood from the left atrium to the left ventricle during (ventricular) diastole, and the pressures in the left atrium and the left ventricle during diastole will be equal. The result is that the left ventricle gets filled with blood during early diastole, with only a small portion of extra blood contributed by contraction of the left atrium (the atrial kick) during late ventricular diastole. Patients with mitral stenosis prompts a series of hemodynamic changes that frequently cause deterioration of the patient's clinical status. A reduction in cardiac output, associated with acceleration of heart rate and shortening of the diastolic time, frequently leads to congestive heart failure. In addition, when AF sets in, systemic embolization becomes a real danger. Please undergo echocardiography test and check whether you have other heart defects such as mitral regurgitation and aortic insufficiency.

- Q: So outside we have a gas grill. There is a valve to turn when you want to use it. U can only hear the gas going when u turn the burner knobs but say u left the valve open and no knobs turned at all for 5 hours is gas escaping or does it only escape when the grills knobs are turned? Thanks

- The valves on the grill itself are the ones that allow the gas to flow. As long as you have no leaks between the main valve and the grill valves, no gas will flow when the valves on the grill are turned to the off position.

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 250 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords